Plastic rubber gas-blowing foaming injection machine for footwear

A technology of blowing foaming and injection molding machine, which is applied in the application, household components, household appliances and other directions, can solve the problems of declining product qualification rate, unfavorable production, over-burning of materials, etc., to achieve convenient operation and maintenance, and reduce cold material. The effect of producing and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

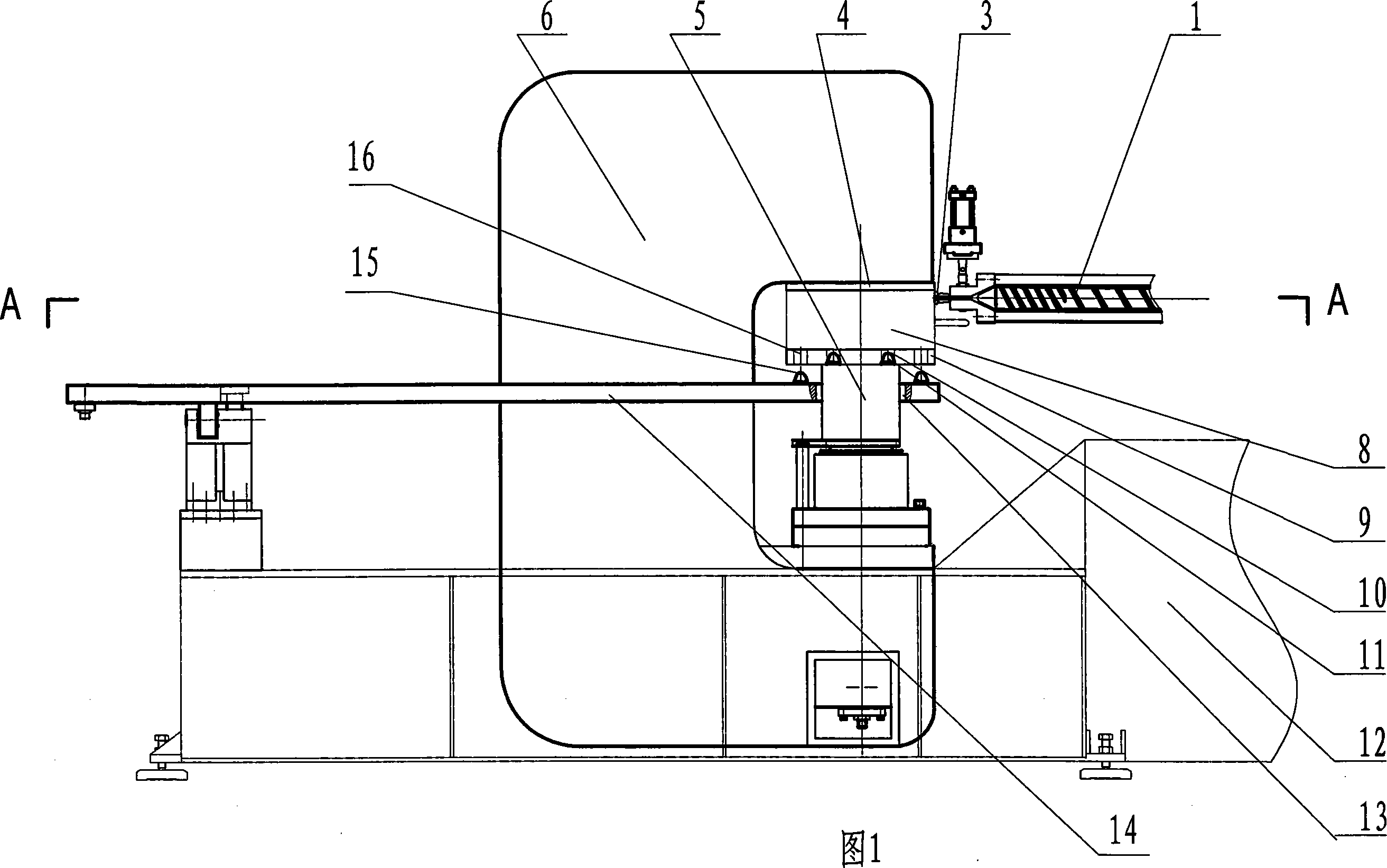

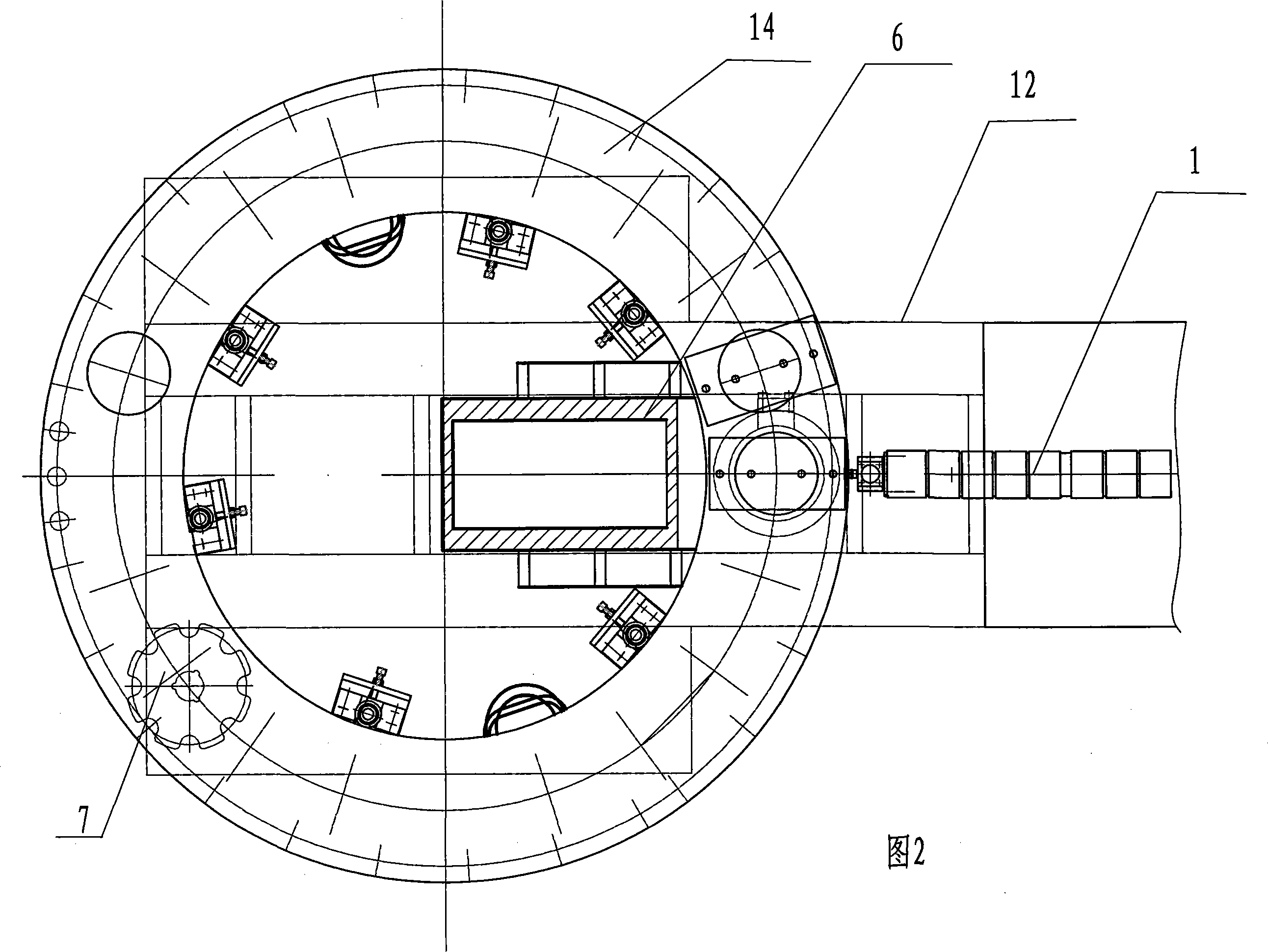

[0009] As shown in Figures 1 and 2, this embodiment includes an injection mechanism 1, a mold clamping mechanism, a turntable 14, a rotary disk mechanism 7, and a frame 12, wherein the mold clamping mechanism includes a mold clamping booster cylinder 5, a jaw type Clamping bracket 6, the injection nozzle 3 in the injection mechanism and the jaw end of the jaw-type clamping bracket are set facing each other, the mold clamping booster cylinder 5 is arranged under the turntable 14, and is placed on the jaw of the jaw-type clamping bracket 6 On the lower surface, the rotary plate 14 corresponding to the clamping pressurized cylinder 5 is provided with a moving channel 13 of the clamping pressurized cylinder 5. There are positioning devices (15, 16), a positioning connection device (10, 11) is provided between the mold positioning plate 9 and the mold clamping booster cylinder 5, and a mold is provided on the upper surface of the jaws of the jaw-type clamping bracket 6 cover plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com