Heavy bamboo multi-layer composite floor

A multi-layer composite and heavy bamboo technology, applied in the direction of insulation layer, floor, building, etc., can solve the problems of delaying production efficiency, wasting manpower, floor strength, hardness, and service life can not fully meet the actual use requirements, and achieve the appearance The effect of real beauty and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

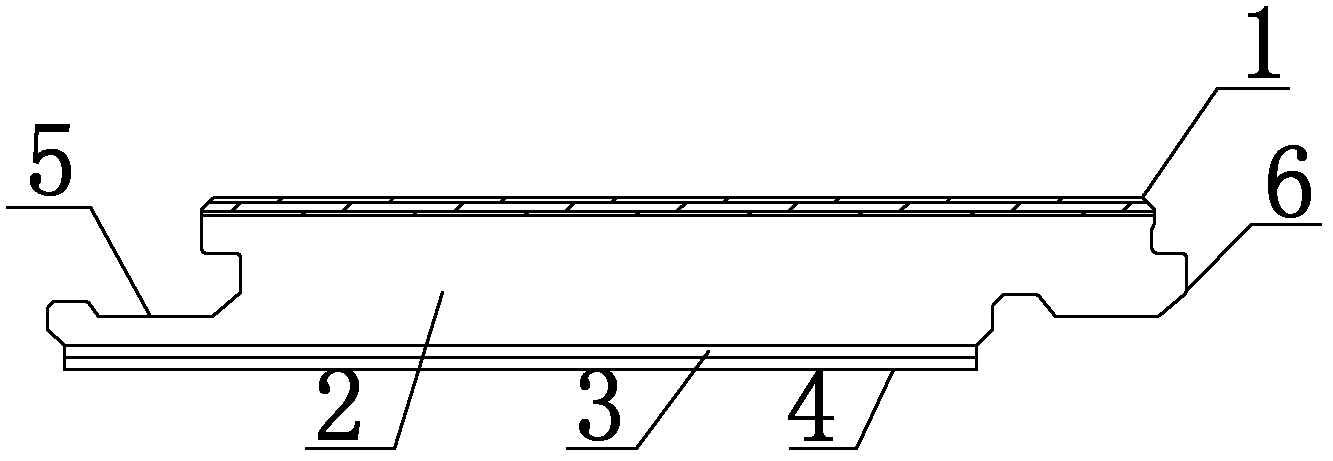

[0017] Such as figure 1 As shown, the heavy bamboo multilayer composite floor of the present invention, in the initial stage of the production process, at first the moso bamboo is sliced, and the heavy bamboo multilayer composite floor includes the heavy bamboo panel layer 1 successively from top to bottom. , MDF layer 2, poplar cortex 3 and mute cushion layer 4, which are glued and connected in turn; both sides in the width direction of the MDF layer 2 are respectively provided with a tongue and groove 5 and a tongue 6, which can also be arranged in a straight Groove structure; the heavy bamboo panel layer 1 is composed of carbonized bamboo fibers, and the heavy bamboo panel layer 1 is formed by pressing bamboo filaments, then steamed or carbonized, then dipped and dried, and finally sliced and Balance; the sound-absorbing cushion layer 4 is a foam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com