Softening and adhering device for production of plastic shoe boards

A technology for shoe boards and plastics, which is applied in the field of softening and bonding devices for the production of plastic shoe boards, can solve the problems of plastic shoe board softening and bonding position deviation, reduced desire to buy plastic shoes, and weak bonding of plastic shoe boards, etc., to achieve Avoid weak bonding, increase convenience, and use safely and conveniently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

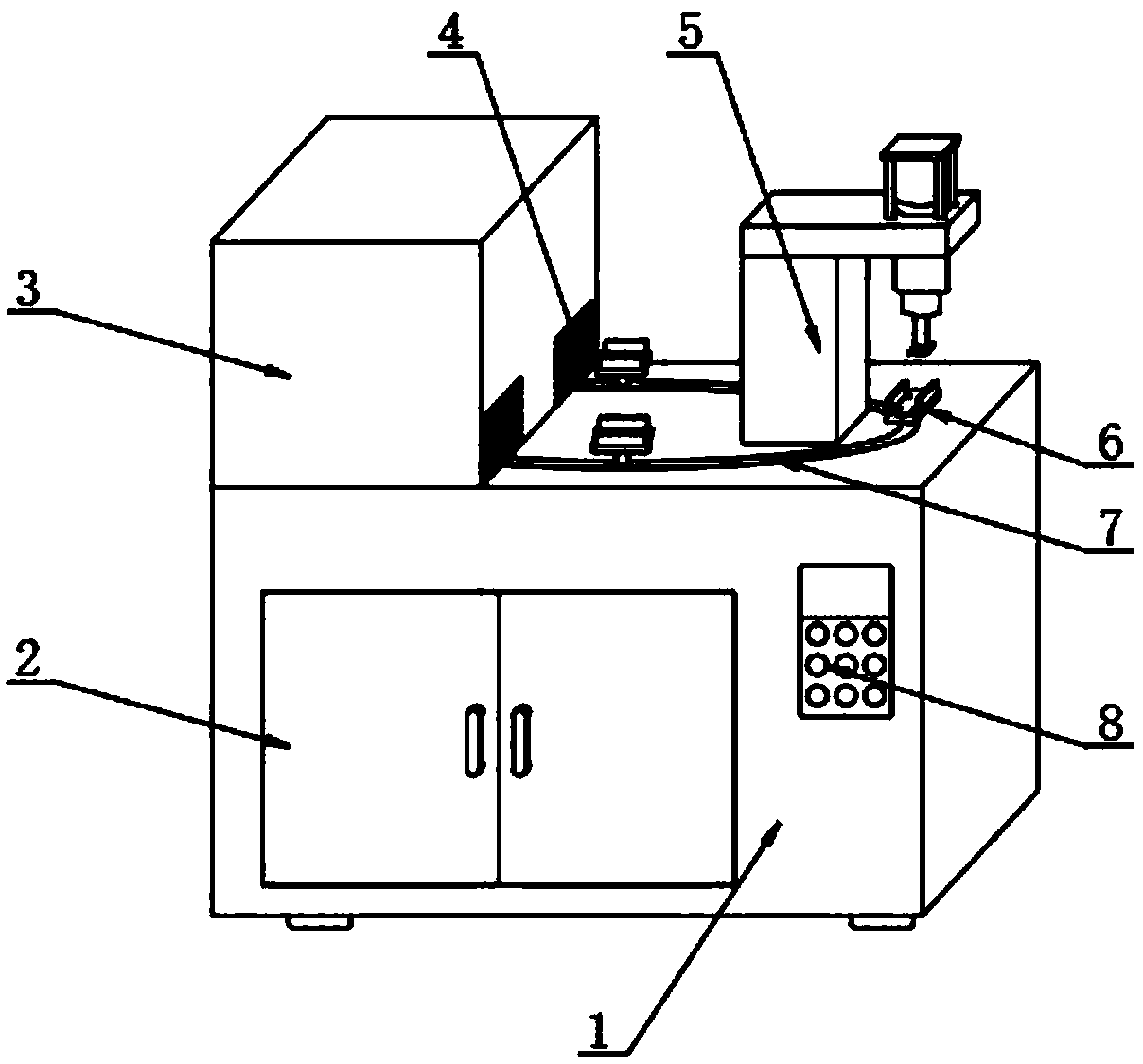

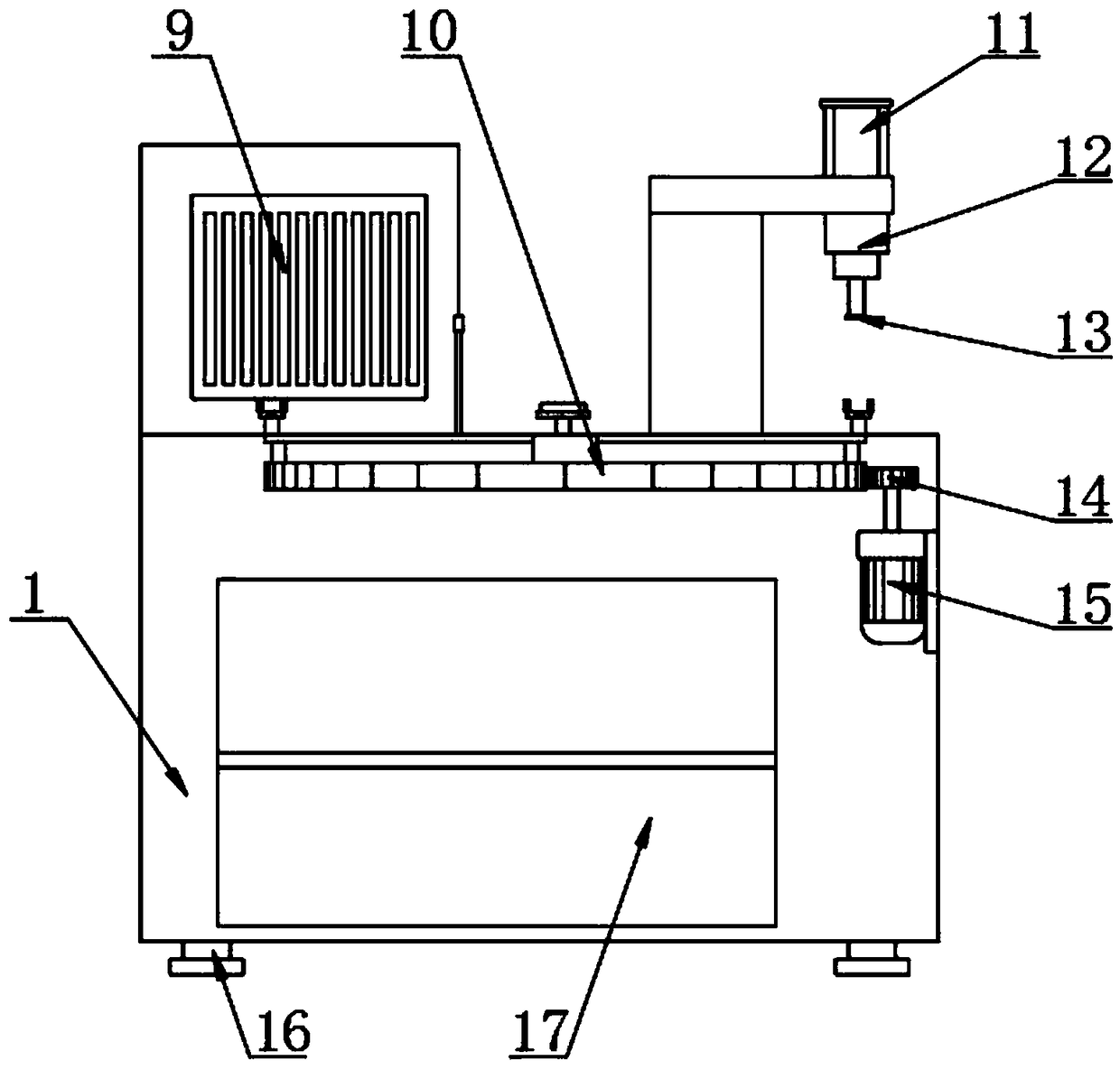

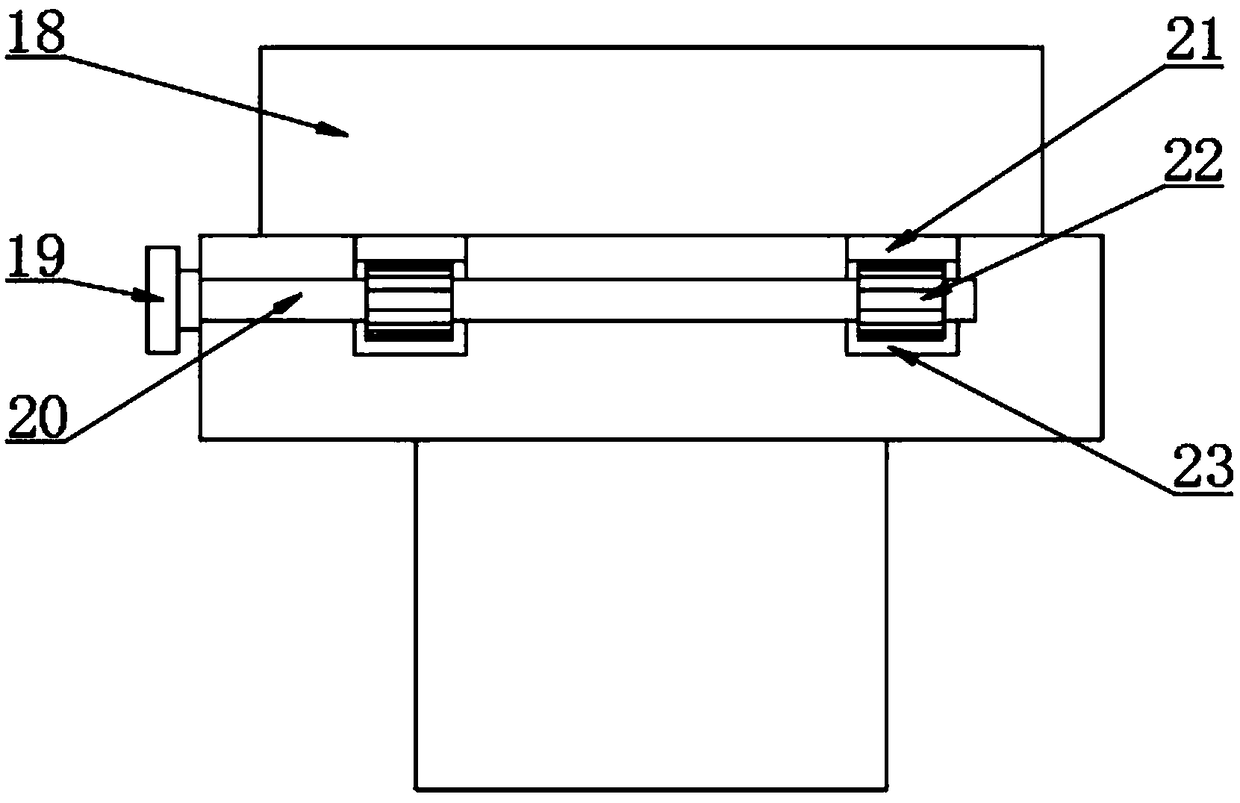

[0021] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a softening and bonding device for plastic shoe board production, including a box body 1, a box door 2, a heating chamber 3, a heat insulation curtain 4, a support seat 5, a placement plate 6, a rotating Ring 7, control switch 8, heating plate 9, rotating gear 10, air pump 11, telescopic column 12, pressure plate 13, first transmission gear 14, motor 15, anti-slip mat 16, storage bin 17, splint 18, adjustment knob 19 , transmission rod 20, slider 21, second transmission gear 22 and chute 23, one side of the box body 1 is movably connected with the box door 2, in order to avoid corrosion and damage to the box body 1 after long-term use, the box body 1 The outside is coated with antirust coating, and one side of chamber door 2 is equipped with control switch 8.

[0022] One side of the top of the box body 1 is fixedly connected with a heating chamber 3, and the inner wall of one s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com