Coated leather-like sole and manufacture method thereof

A manufacturing method and imitation leather technology, applied in shoe soles, footwear, apparel, etc., to reduce the harm to workers and the environment, prolong the aging time, and reduce the amount of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The rubber and plastic melt is poured into the flat mold and vulcanized for 5 minutes to form, and then pressed into a rubber and plastic flat plate with a hydraulic press. Use a grinding wheel to polish one side of the rubber and plastic plate, wash it with water, and dry it for later use.

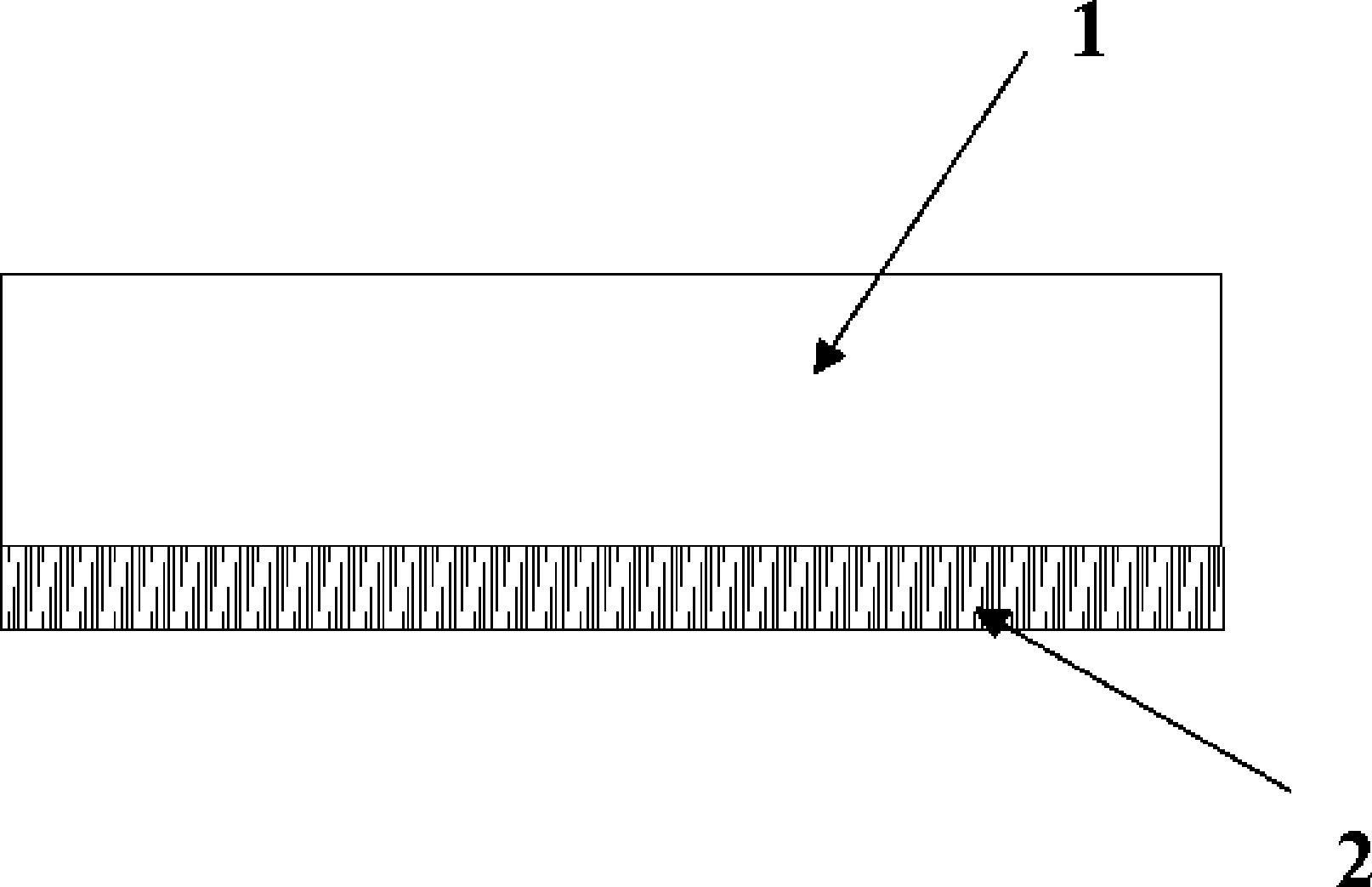

[0028] Print rubber treatment agent (Nanguang Resin, Model 793) on the smooth surface of the rubber-plastic flat plate, print hot-melt glue after drying, and use a laminating machine to print solid-color composite transfer film paper on the aforementioned treated rubber-plastic flat plate. The temperature of the laminating machine is controlled at 90°C, and the finished imitation leather sole is shown in figure 1 . The surface of the sole is flat and smooth, and the composite transfer film 2 is firmly attached and has a matt color.

Embodiment 2

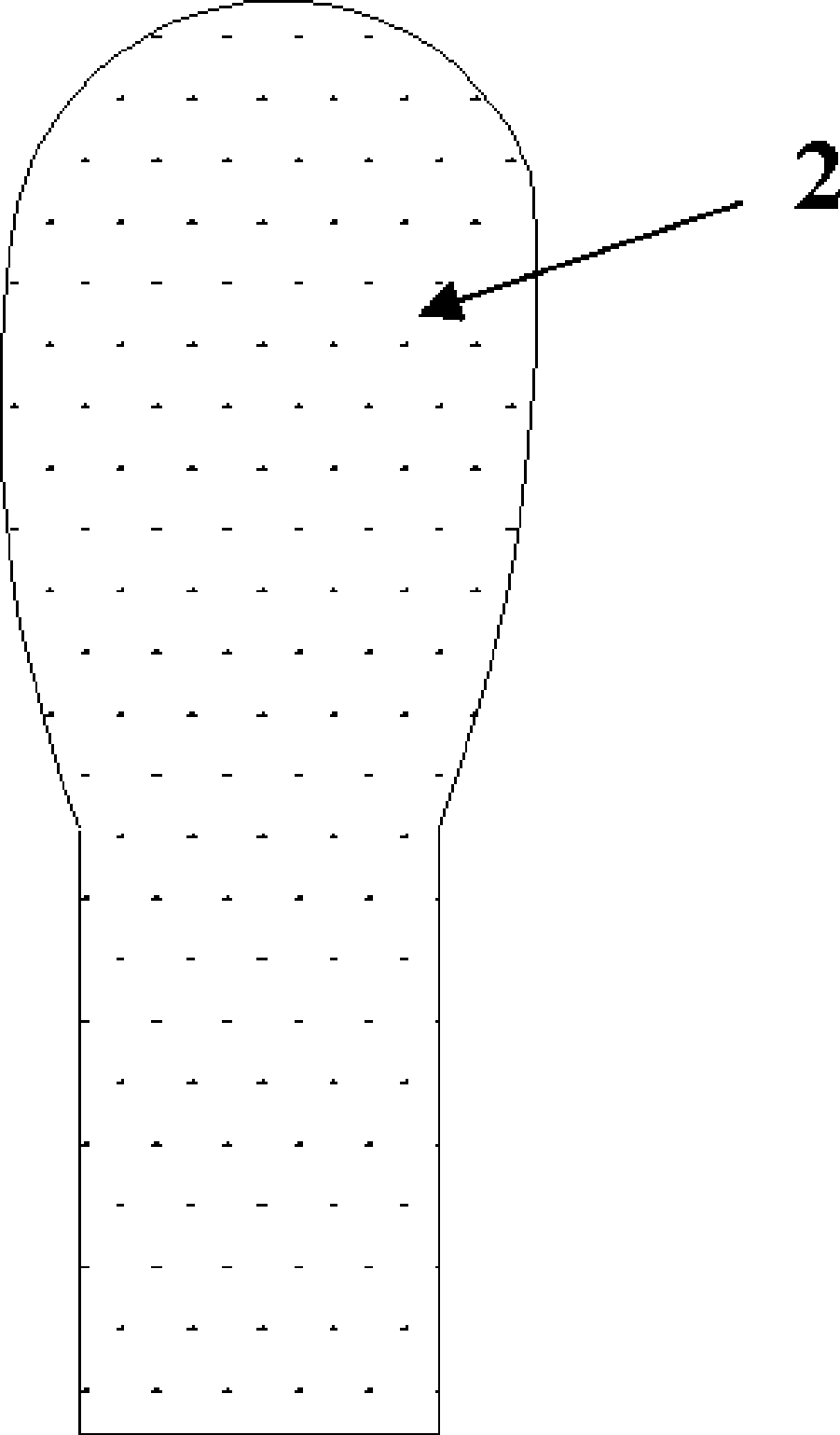

[0030] Method is the same as Example 1, except that the adhesive used is varnish, and after printing rubber treatment agent, before printing adhesive, one layer of rubber paint is printed more, to increase the flatness of rubber and plastic soles, the compound transfer used Membrane paper tape pattern, the temperature is 100 ℃ when laminating, see the finished product of imitation leather sole figure 2 . The sole is flat and smooth as a whole, and the composite transfer film is firmly attached, with bright patterns and elegant appearance.

Embodiment 3

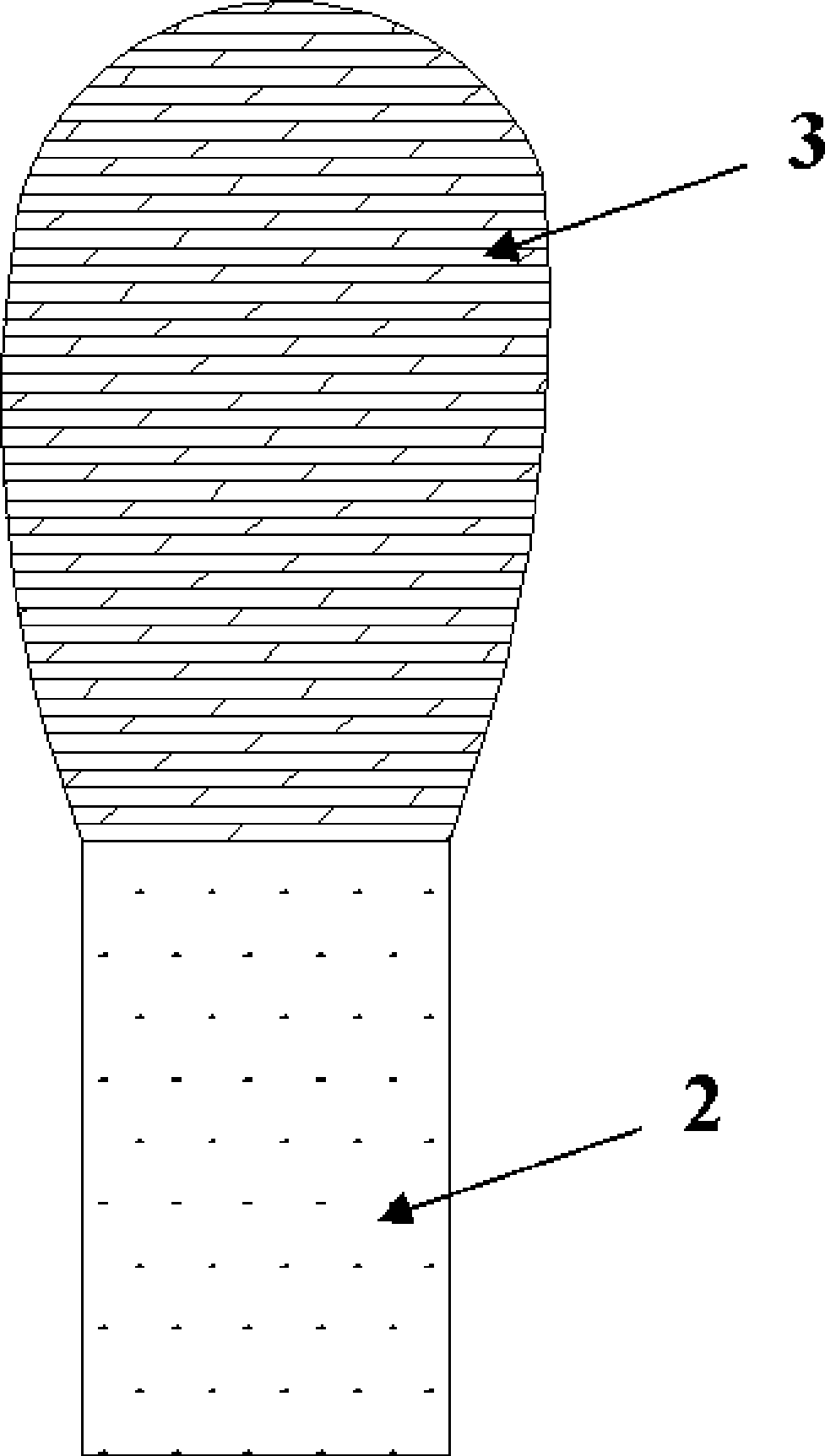

[0032] The method is the same as that in Example 1, except that the adhesive used is PU glue, and the temperature is 110°C when the film is covered. After cooling, place the required embossing mold on the corresponding part of the imitation leather sole, and stamp the film sole with a hydraulic press. Embossed pattern 3 is formed on the surface, which is non-slip, and the finished imitation leather sole is shown in image 3 . The composite transfer film 2 is firmly attached, the forefoot part of the sole is non-slip, and the heel part is smooth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com