Double-silver low-emissivity coated glass and preparation method thereof

A low-emissivity coating and glass technology, applied in chemical instruments and methods, glass/slag layered products, layered products, etc., can solve the problems of redness, ghosting, and softness of the film surface, and achieve soft colors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

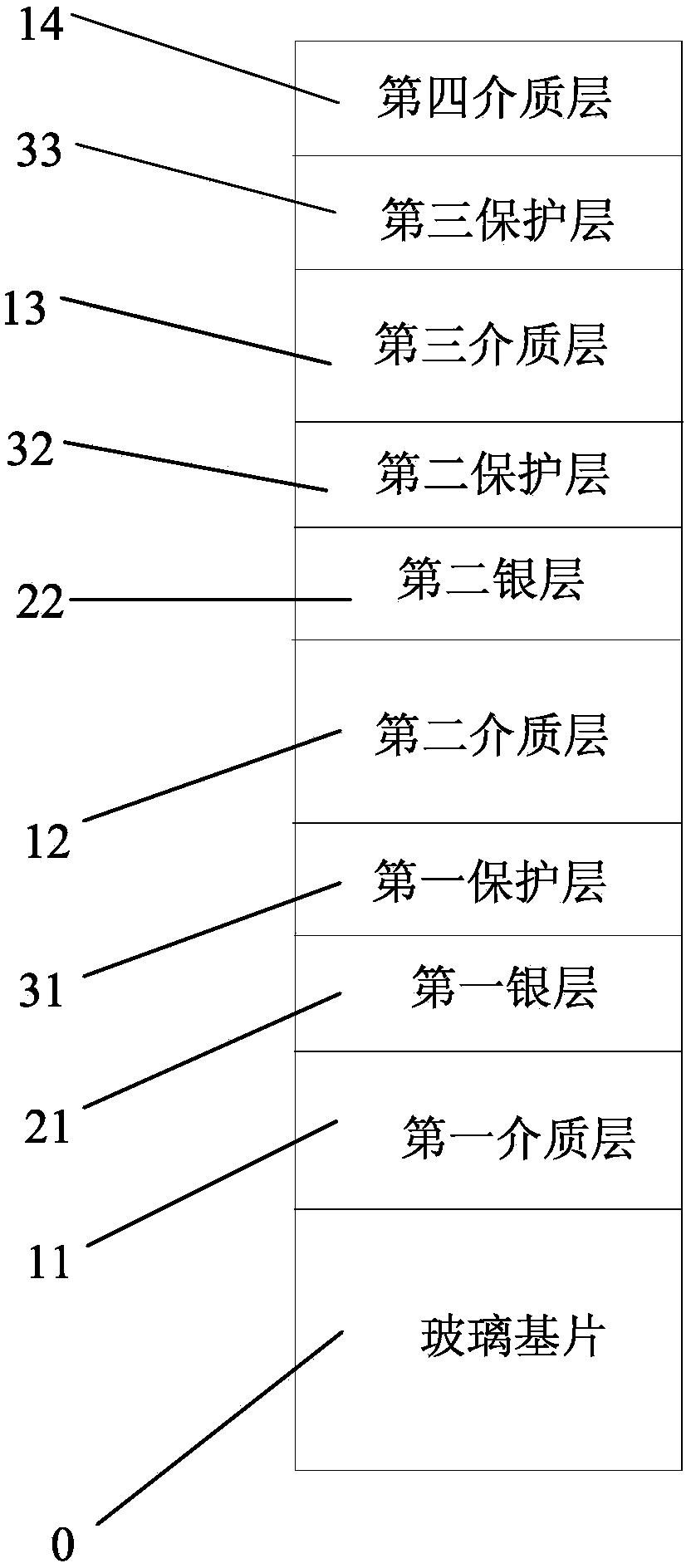

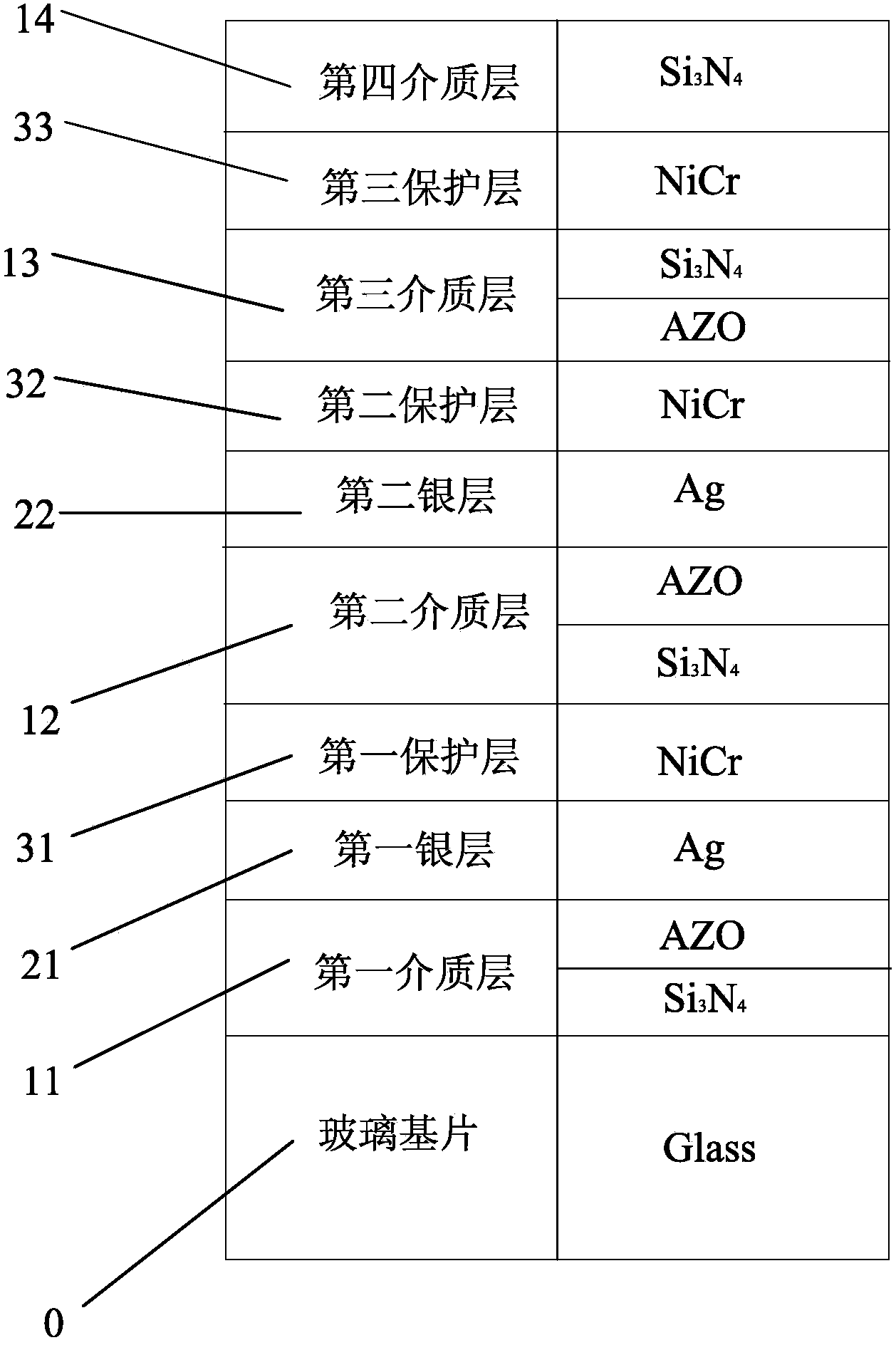

[0023] Such as figure 1 , a double-silver low-emissivity coated glass, comprising a glass substrate O and a film layer coated on the surface of the glass substrate; the film layer is sequentially provided with a thickness of 47nm from one side of the glass substrate outwards The first dielectric layer 11 with a thickness of 5 nm, the first silver layer 21 with a thickness of 5 nm, the first protective layer 31 with a thickness of 3 nm, the second dielectric layer 12 with a thickness of 67 nm, the second silver layer 22 with a thickness of 17 nm, and a thickness of 1 nm The second protective layer 32, the third dielectric layer 13 with a thickness of 31nm, the third protective layer 33 with a thickness of 3nm, and the fourth dielectric layer 14 with a thickness of 24nm, wherein the first dielectric layer 11, the second dielectric layer 12 , the third dielectric layer 13 and the fourth dielectric layer 14 are all Si 3 N 4 layer, the first protective layer 31, the second protec...

Embodiment 2

[0030] A double-silver low-emissivity coated glass, comprising a glass substrate O and a film layer coated on the surface of the glass substrate; the film layer is sequentially provided with a thickness of 53nm from one side of the glass substrate outwards The first dielectric layer 11, the first silver layer 21 with a thickness of 3nm, the first protective layer 31 with a thickness of 3nm, the second dielectric layer 12 with a thickness of 73nm, the second silver layer 22 with a thickness of 18nm, and the The second protective layer 32, the third dielectric layer 13 with a thickness of 23nm, the third protective layer 33 with a thickness of 1nm, and the fourth dielectric layer 14 with a thickness of 25nm, wherein the first dielectric layer 11 is formed from the glass substrate 0 to The outside is sequentially provided with Si with a thickness of 50nm 3 N 4 layer and an AZO layer with a thickness of 3nm, and the second dielectric layer 12 is sequentially provided with Si with...

Embodiment 3

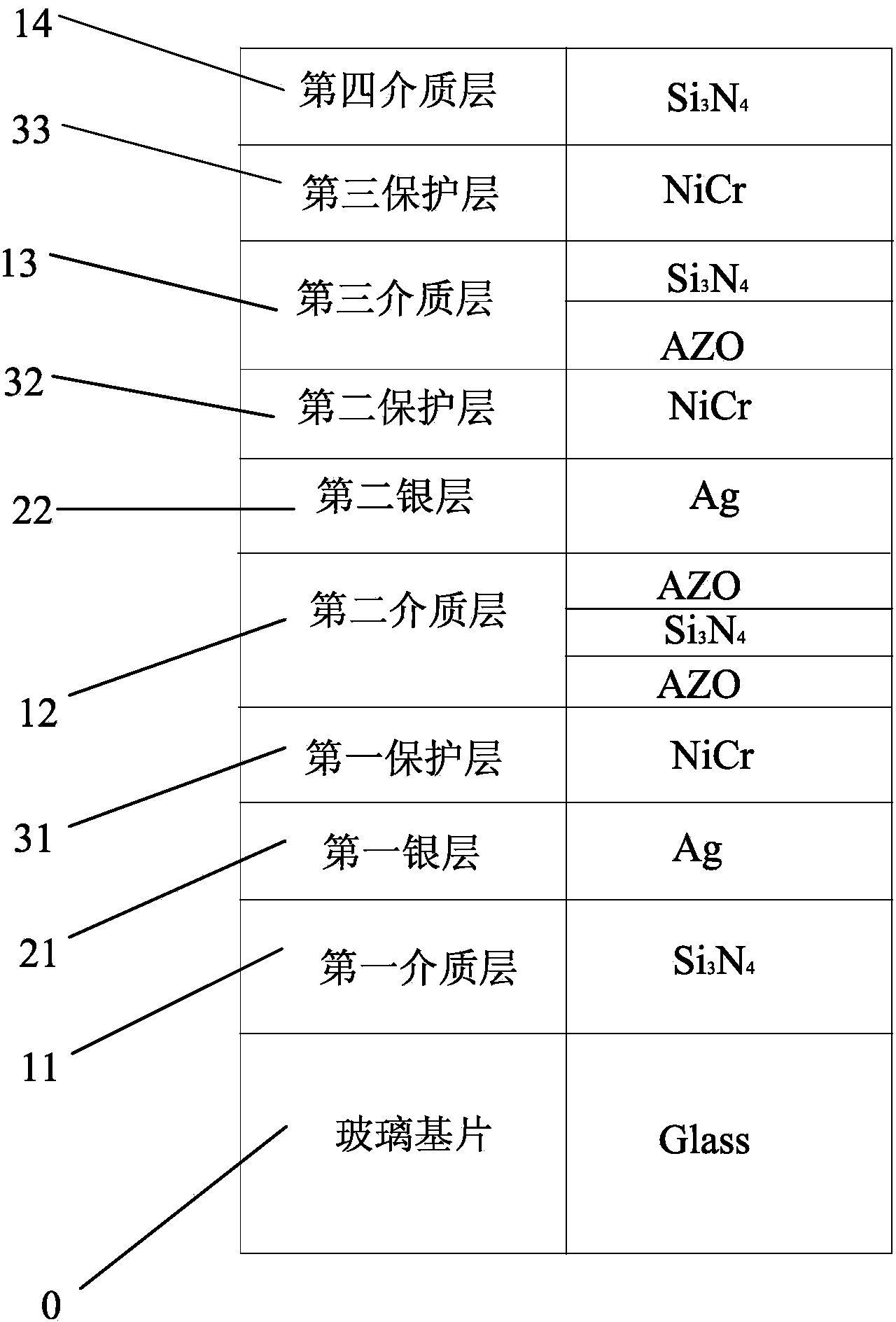

[0036] A double-silver low-emissivity coated glass, comprising a glass substrate O and a film layer coated on the surface of the glass substrate; the film layer is sequentially provided with a thickness of 53nm from one side of the glass substrate to the outside. A dielectric layer 11, a first silver layer 21 with a thickness of 6 nm, a first protective layer 31 with a thickness of 3 nm, a second dielectric layer 12 with a thickness of 60 nm, a second silver layer 22 with a thickness of 10 nm, and a first protective layer 31 with a thickness of 5 nm. Two protective layers 32, a third dielectric layer 13 with a thickness of 37nm, a third protective layer 33 with a thickness of 1nm, and a fourth dielectric layer 14 with a thickness of 30nm, wherein the first dielectric layer 11 is Si 3 N 4 layer, and the second dielectric layer 12 is sequentially provided with an AZO layer with a thickness of 5 nm and a Si layer with a thickness of 45 nm from the glass substrate 0 to the outside...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com