Plastic foam for sport shoe sole

A technology for sports shoes and soles, applied in the field of plastics, can solve the problems of lowering sports performance, unable to change the properties of soles, poor elasticity, etc., and achieve the effect of reducing physical energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

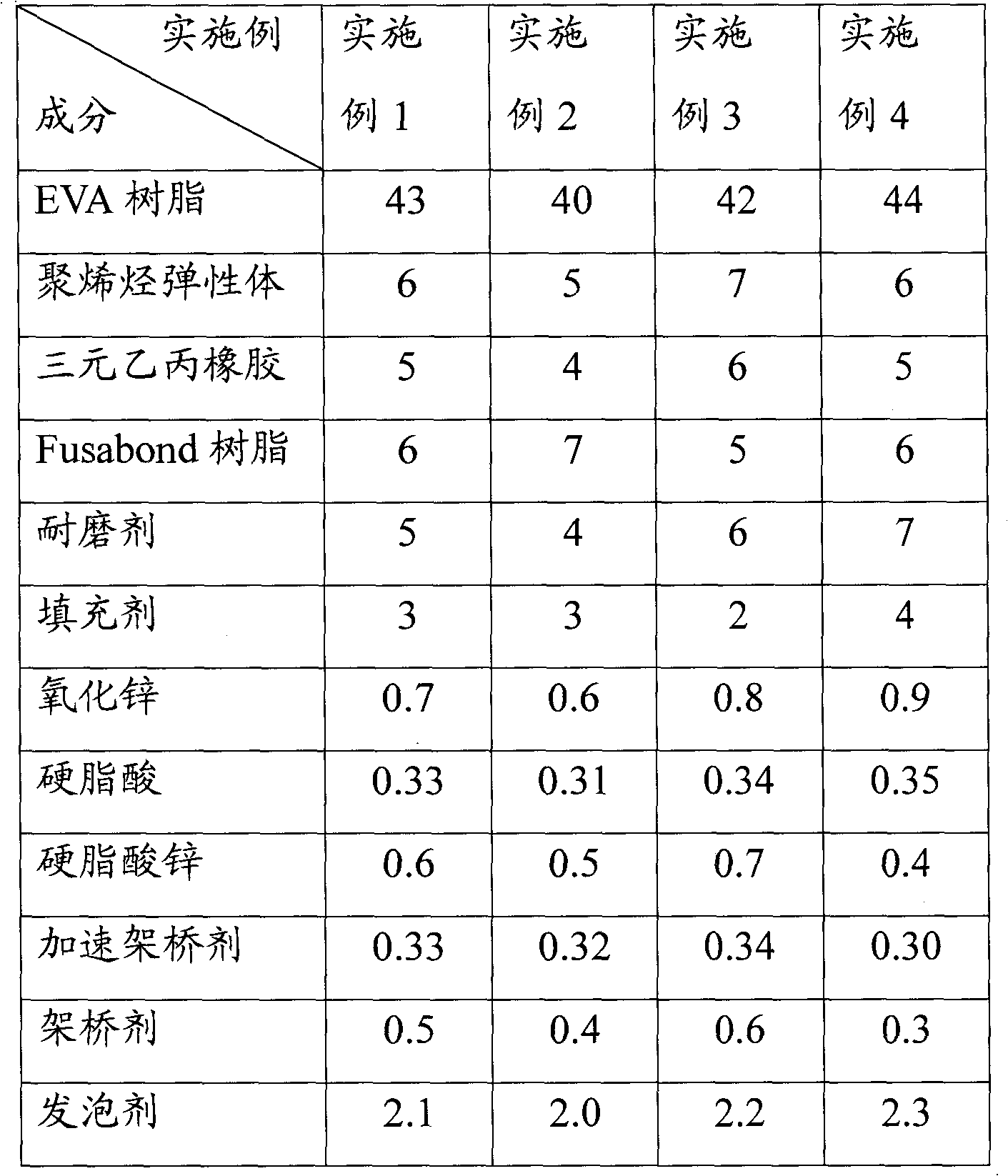

[0045] A foamed plastic for sports shoe soles, comprising the following components in parts by weight:

[0046] Ethylene-vinyl acetate copolymer 70~74

[0047] Ethylene-octene copolymer 8~12

[0048] EPDM 6~10

[0049] Ethylene-acrylic acid copolymer 8~12

[0050] Wear-resisting agent 8~9

[0051] Filler 4~6

[0053] Stearic acid 0.5~0.6

[0055] Accelerated bridging agent 0.5~0.7

[0056] Bridging agent 0.8~0.9

[0057] Foaming agent 3.2~3.8

[0058] Among them, EPDM rubber is a terpolymer of ethylene-propylene and non-conjugated diene.

[0059] The preparation method of the above-mentioned foamed plastic for sports shoe soles is as follows: each component is weighed and mixed uniformly; the product is matured and cured in a pouring machine.

[0060] The present invention will be described in detail below in conjunction with specific embodiments. The description in this part is only exemplary and explanator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com