Self-service safety perforator

A safe, punching machine technology, used in maintenance and safety accessories, manufacturing tools, boring/drilling, etc., can solve problems such as operator health impact, polluted working environment, flying debris, etc., to ensure drilling Quality, easy to operate, to achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

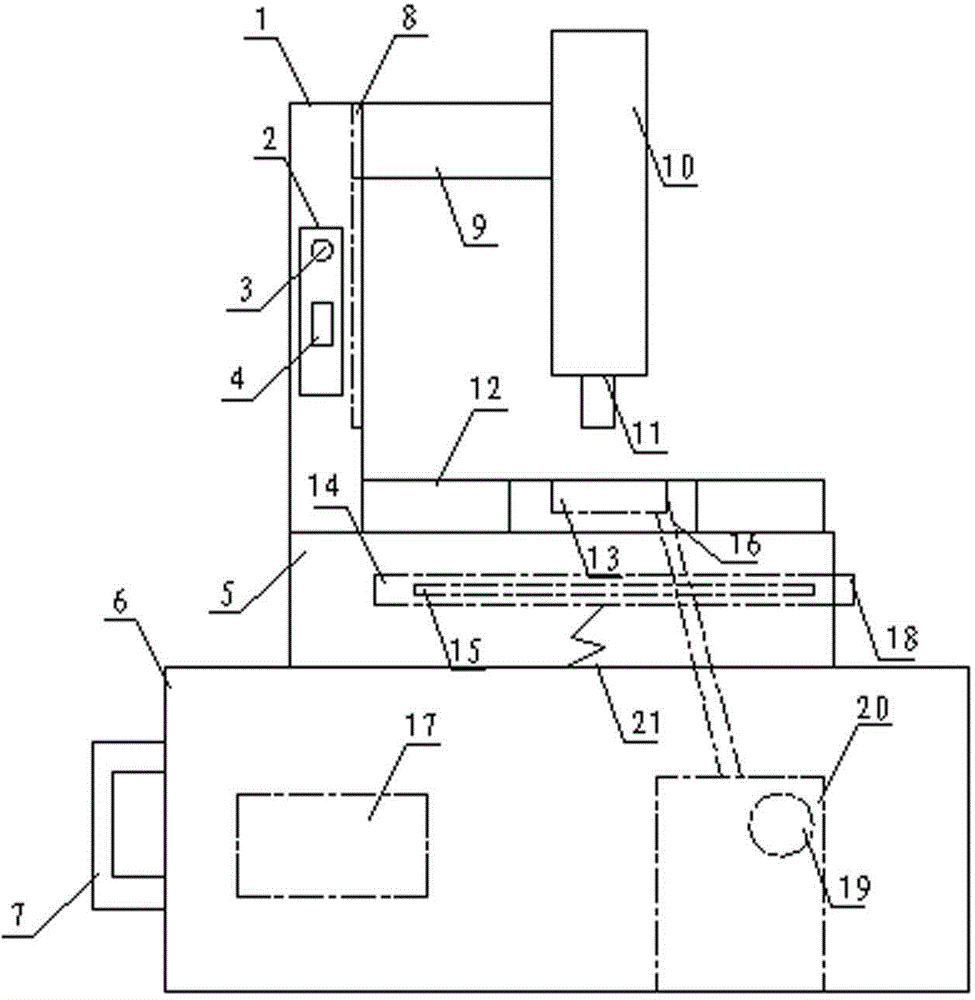

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0019] like figure 1 As shown, a safety punching machine with self-service function according to the present invention includes a base 6, a positioning module 5, a pillar 1, a slide bar 9, a push rod 10 and a drill bit 11, and the positioning module 5 is set on the base 6 , the upper end of one side of the positioning module 5 is provided with a pillar 1, one side of the pillar 1 is connected to the ejector rod 10 through the slide bar 9, and the drill bit 11 is arranged at the lower end of the ejector rod 10; The platform 12 is provided with a motor 17 in the base 6, and the motor 17 is connected to the drill bit 11 to move. The invention is not only simple in structure and easy to operate, but also can ensure the drilling quality. A fixed groove 13 is provided in the workbench 12, a chip storage tank 20 is provided in the base 6, the chip st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com