Constructing process of cast-in-situ bored piles

A technology for bored piles and construction technology, which is applied to sheet pile walls, infrastructure engineering, buildings, etc. Ensure drilling quality and accuracy, prevent tilting or shifting, improve the effect of connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0038] A construction technique for bored piles, comprising the following steps:

[0039] S1 construction preparation:

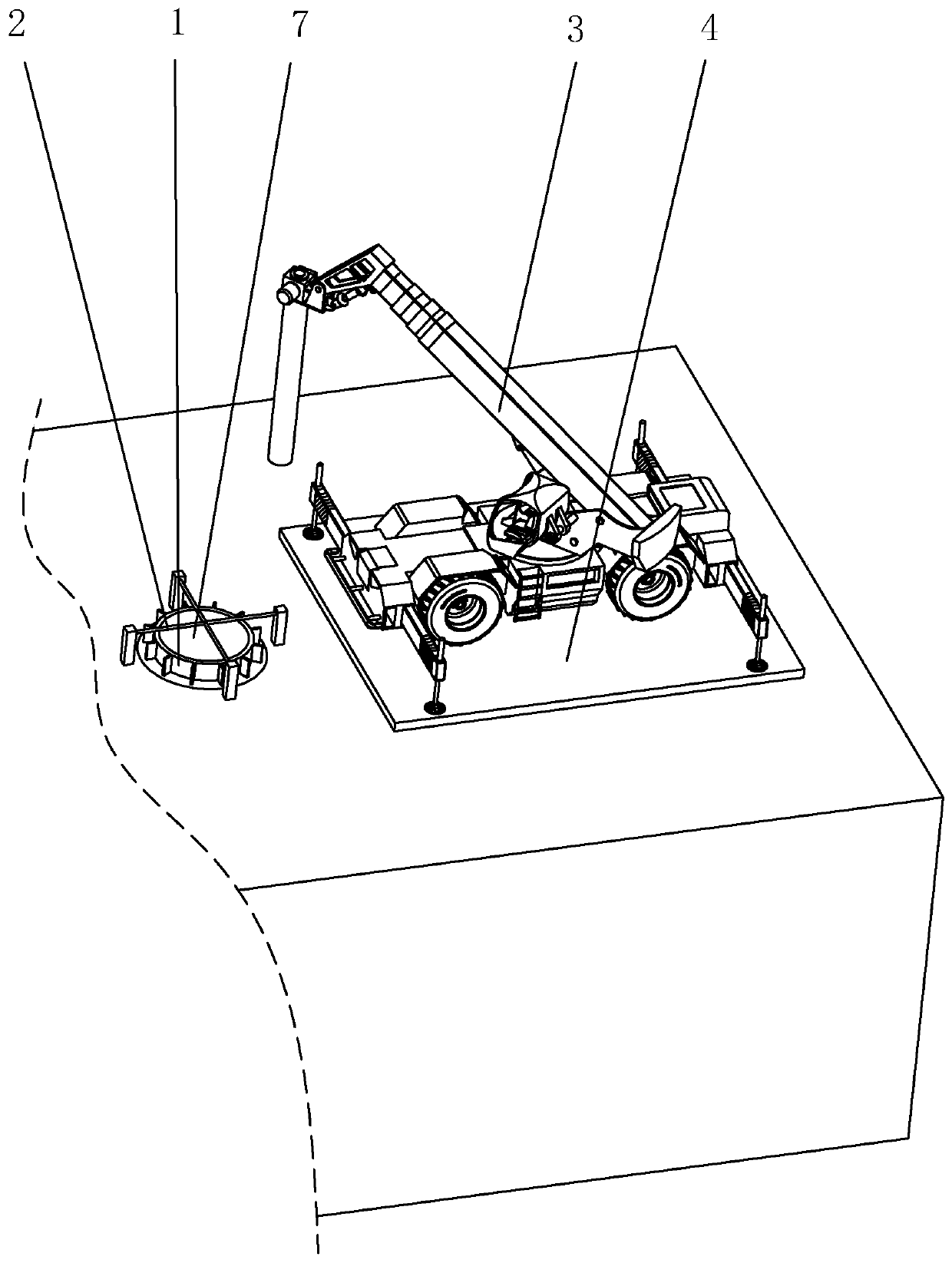

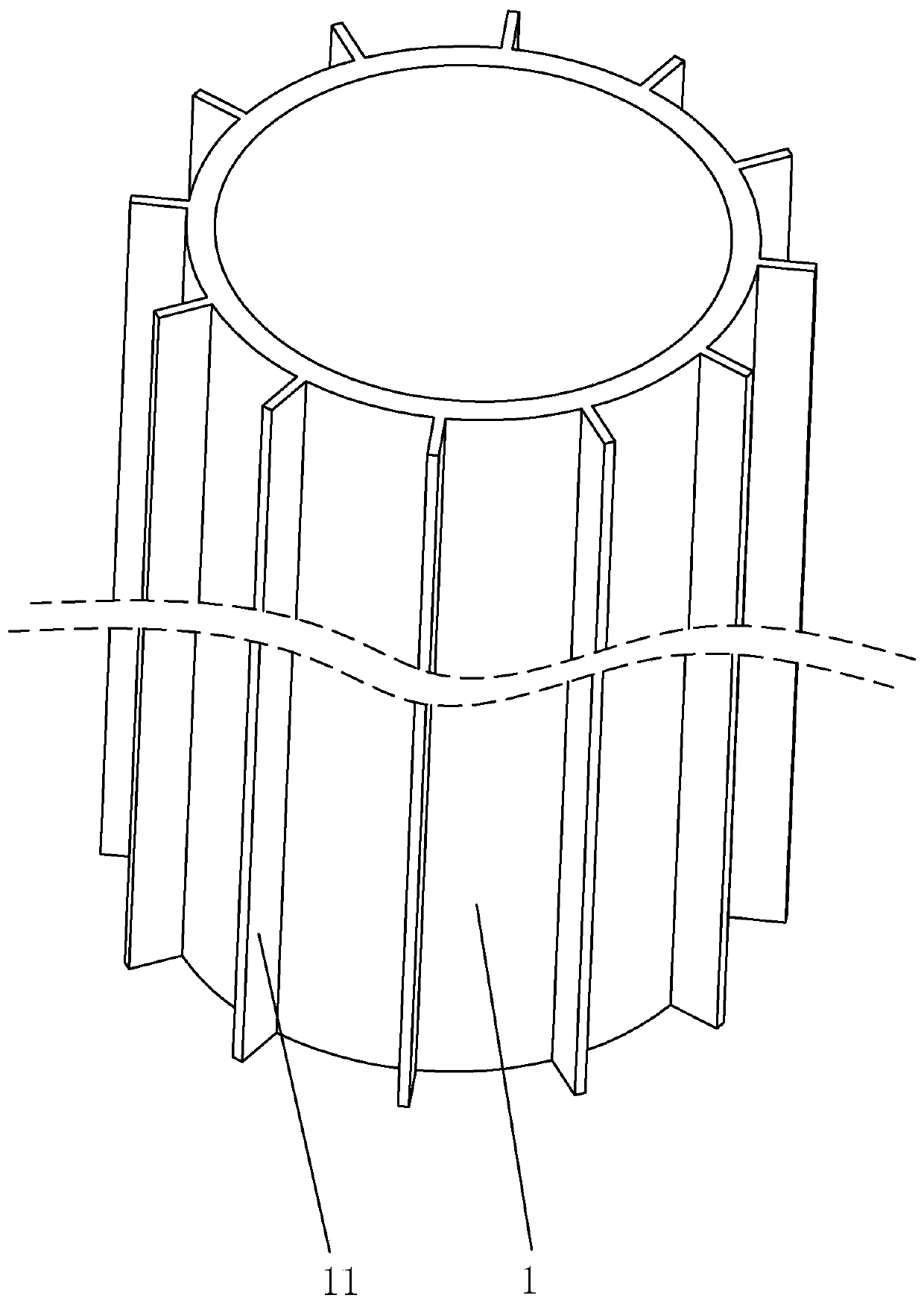

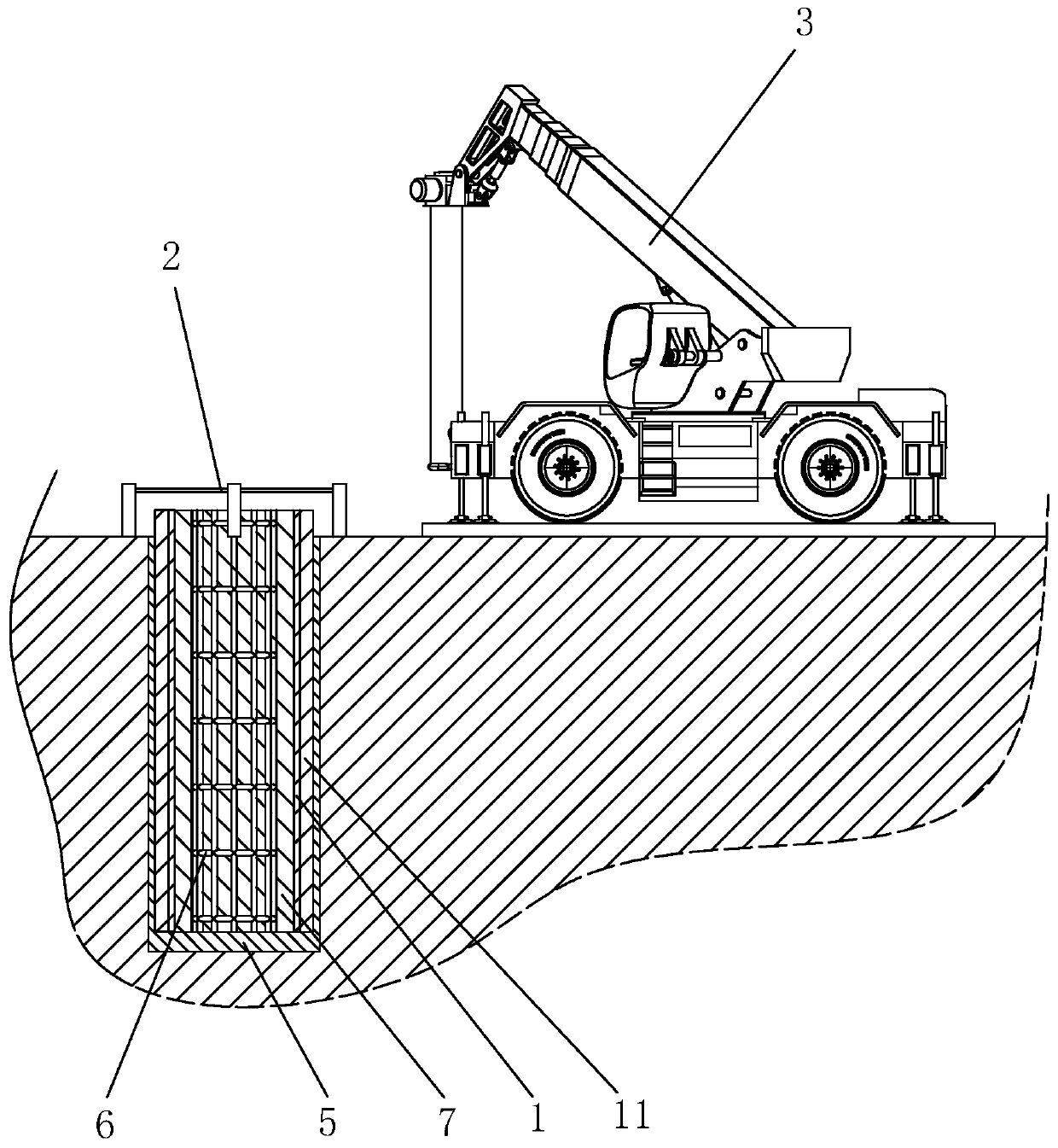

[0040] refer to figure 1 First, find out the situation of buried pipelines, ensure that there are no buried pipelines at the drilling position, then level the construction site, tamp and fill it compactly, and make plans for the placement of mud pools, steel cages 6, conduits, hoppers and construction machinery Make a clear plan to meet the requirements of drilling rig 3 operation and displacement, mud circulation system layout, concrete pouring operation, etc.; then lay road base plate 4 at the drilling rig 3 operation place to prevent drilling rig 3 from being unstable during drilling, causing safety accidents and affecting the project Quality; then dig the mud pool, and do a good job of the mud pool enclosure, and prepare the mud circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com