High-precision multifunctional horizontal spiral drilling rig

A horizontal spiral, multi-functional technology, applied in the direction of rotary drilling rigs, rotary drilling, drill pipes, etc., can solve the problems of high construction conditions, low pipeline connection efficiency, low construction precision, etc., to solve the high construction conditions , Reduce equipment hoisting adjustment time, convenient and safe operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

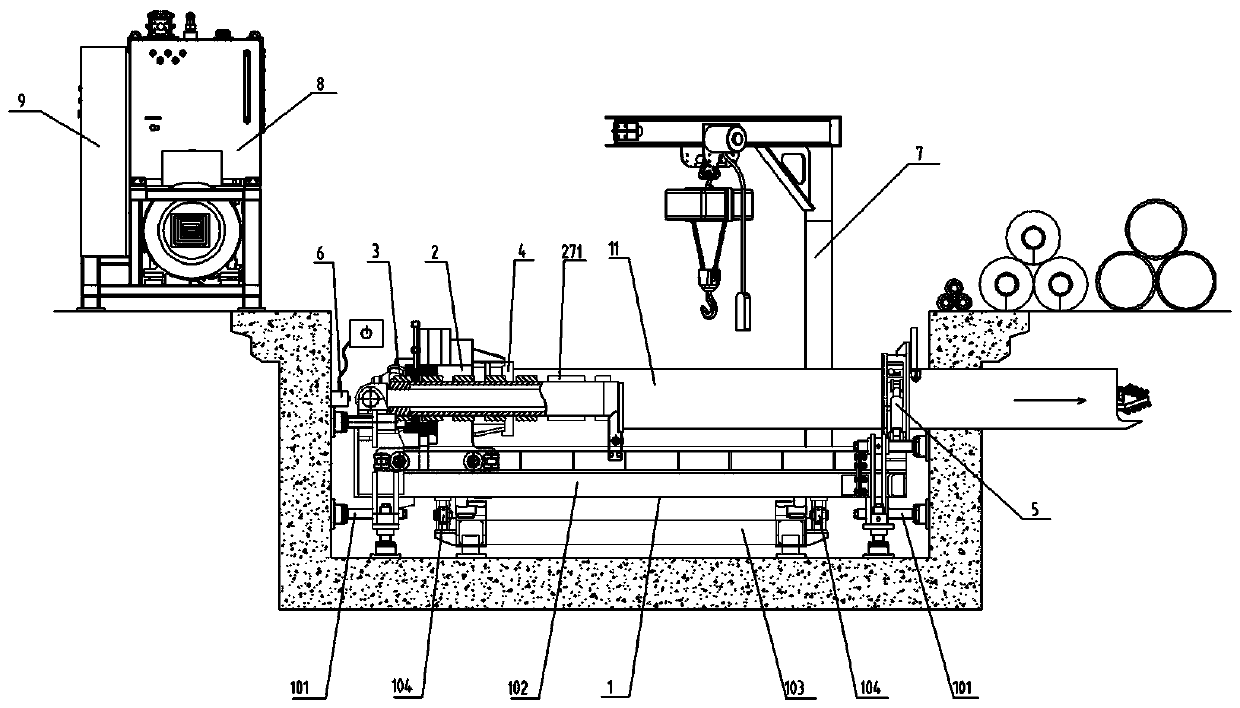

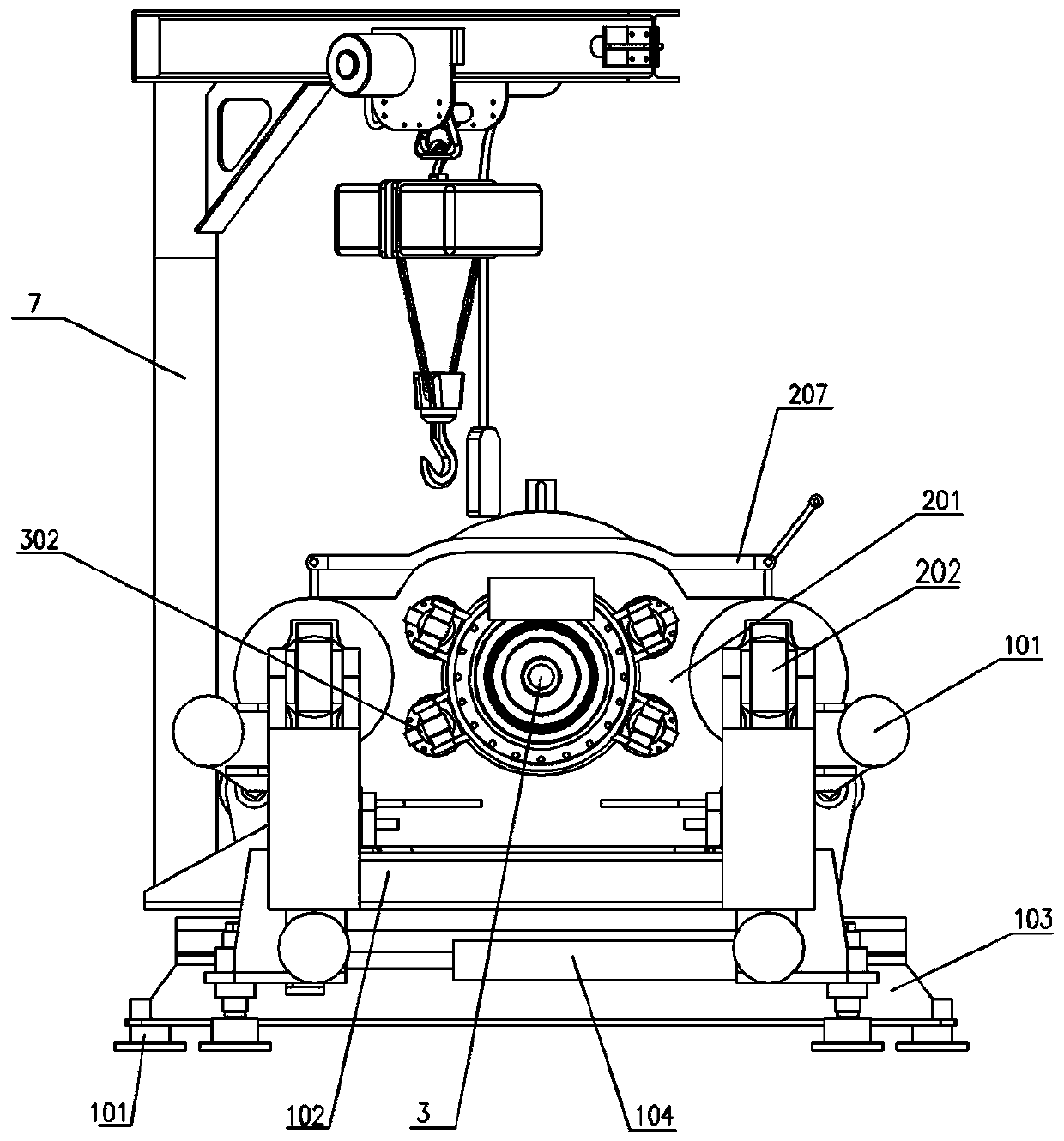

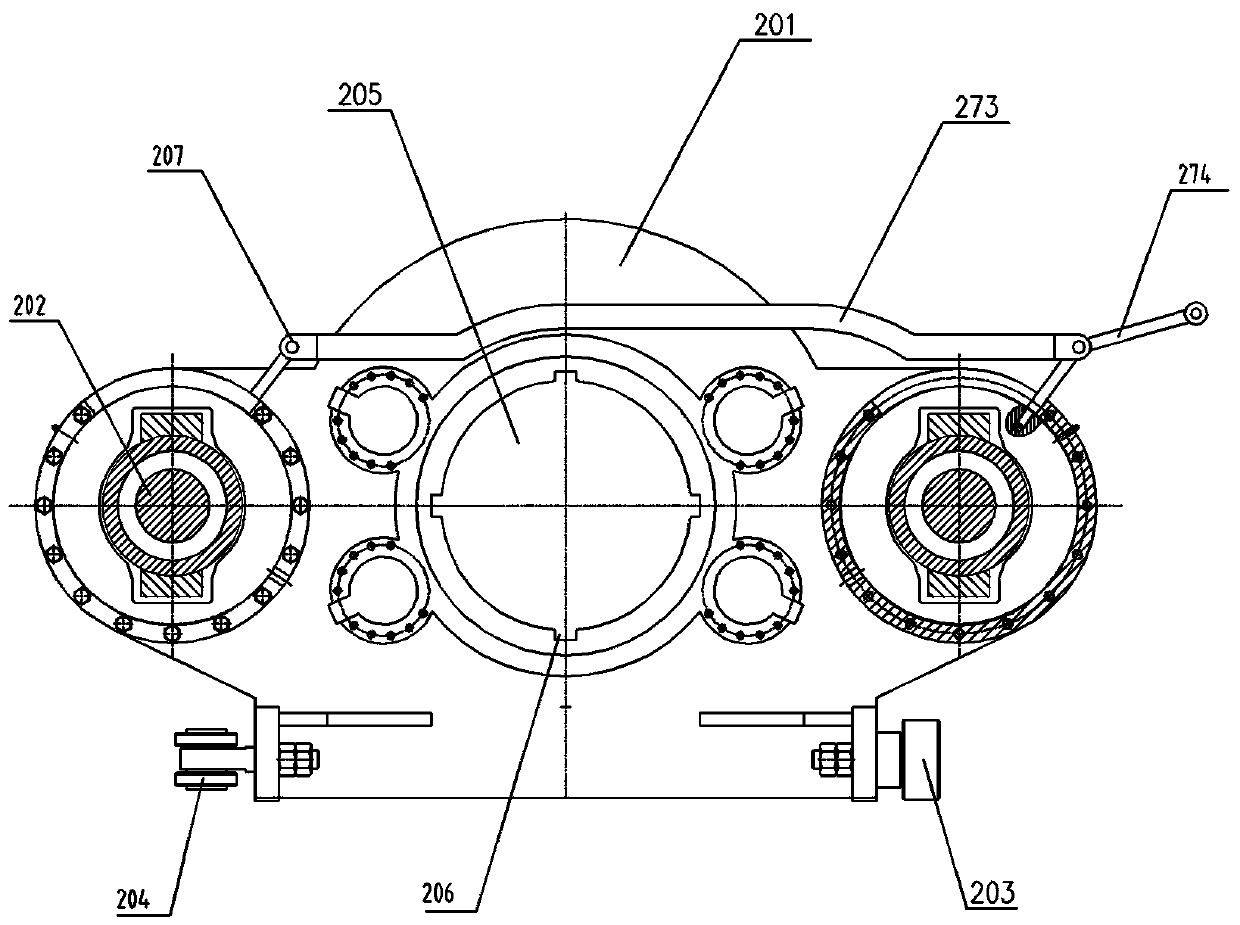

[0034] The high-precision multifunctional horizontal auger drilling machine of the present invention includes a double-layer translation frame 1, a pushing device 2, a driving power device 3, a turning device 4, and a pipe-laying steering device 5, and also includes an optical guide device 6, a lifting Device 7, hydraulic pump station 8 and electrical control cabinet 9, the double-layer translation frame 1 is fixed on the bottom of the foundation pit, the lifting device 7 is fixed on one side of the double-layer translation frame 1, and the optical guide device 6 is fixed on the Push the rear side of the traveling device 2, the pushing traveling device 2 is movably installed on the double-layer translation frame 1, the driving power device 3 is installed in the center of the pushing driving device 2, and the transmission end of the driving power device 3 is fixed The rotary device 4 is installed; the output shaft of the driving power device 3 is connected to the drill pipe 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com