Small-diameter observation well set-shaped steel formwork pouring construction method

A construction method and technology of steel formwork, applied in construction, artificial islands, water conservancy projects, etc., can solve the problems of increased danger for construction personnel, small space for workers to move, difficulty in installing and removing formwork, etc., and achieve good visual quality and mechanized construction The effect of level improvement and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0048] Embodiment 2, build a height and be 18 meters small-diameter observation wells,

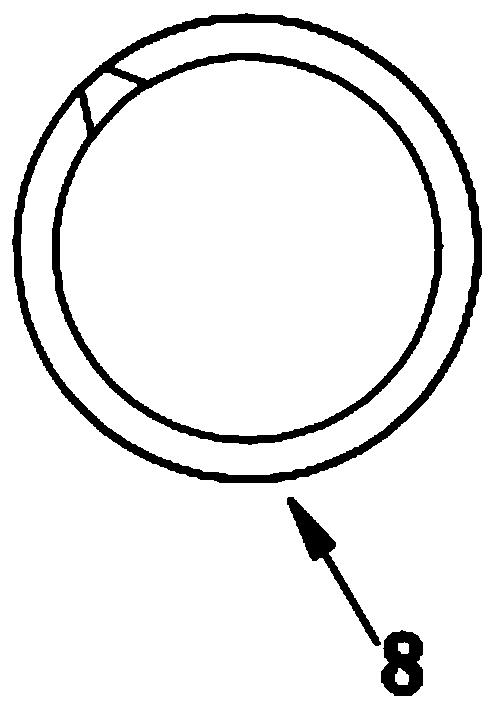

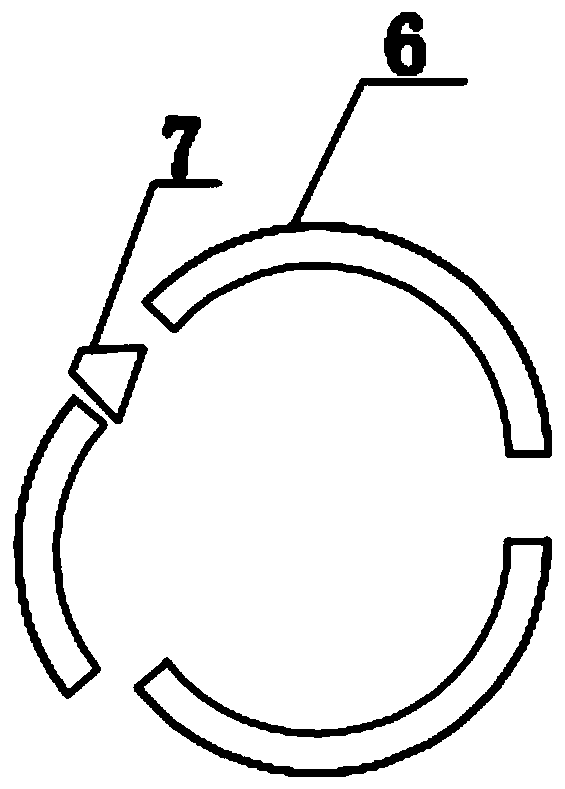

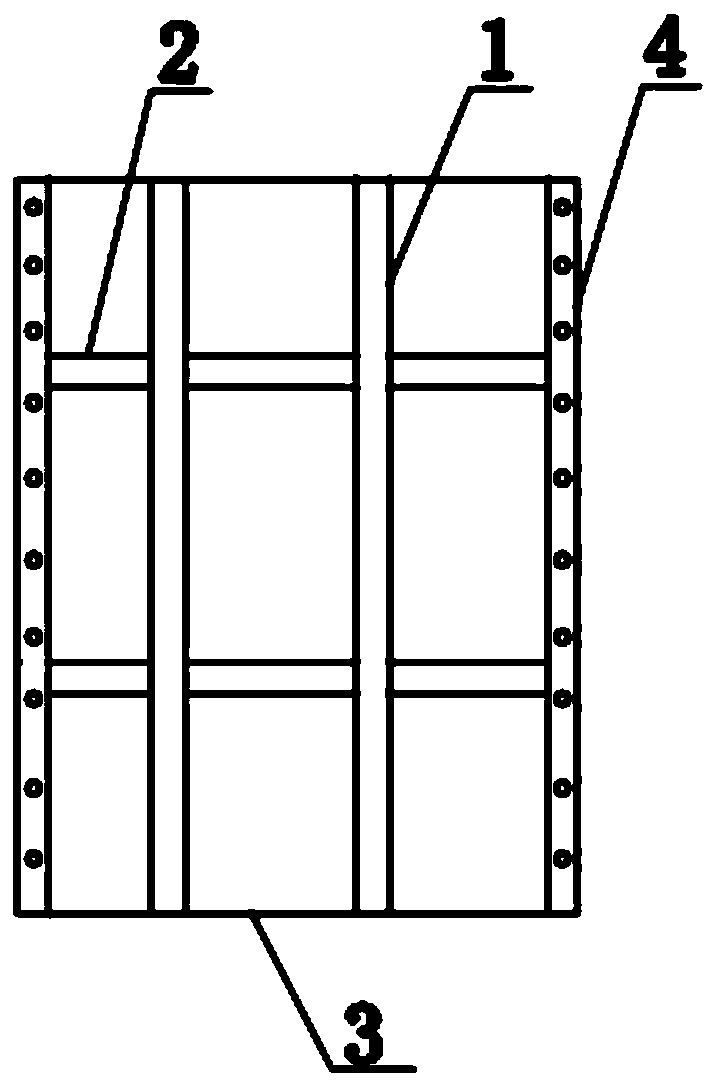

[0049] 1. Formwork production, according to the height of the observation well and the height of each concrete pouring, design a reasonable size of the shaped steel formwork. In the case of this construction method, the observation well is 18m, and the shaped steel formwork is processed to 6m, which can be used for turnover. According to the standard modulus, each section is 1.5m, and the inner and outer steel formworks each need 4 sections. According to construction experience and related calculations, the inner and outer steel formwork panels are made of 5mm thick steel plates, the longitudinal and transverse reinforcement ribs are made of 10×80 ring-shaped steel plates, and the bolt holes of the formwork connecting flanges and longitudinal connecting plates are M20 high-strength Bolt preparation. Each section of outer steel formwork is composed of 2 semi-circular arc steel formworks. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com