Support for hole drilling and rebar planting of indoor building top and wall column side face and construction method thereof

A technology for building and planting steel bars, applied in the direction of building structure, building, housing structure support, etc., can solve the problems of construction time lag, inconvenient operation, low construction efficiency, etc., to avoid potential safety hazards and accidents, save time and The effect of physical strength and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

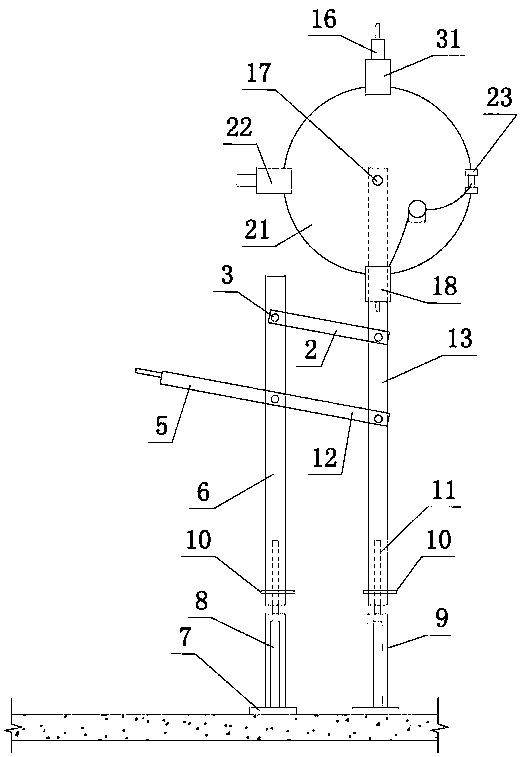

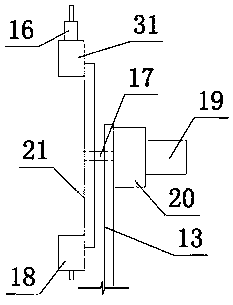

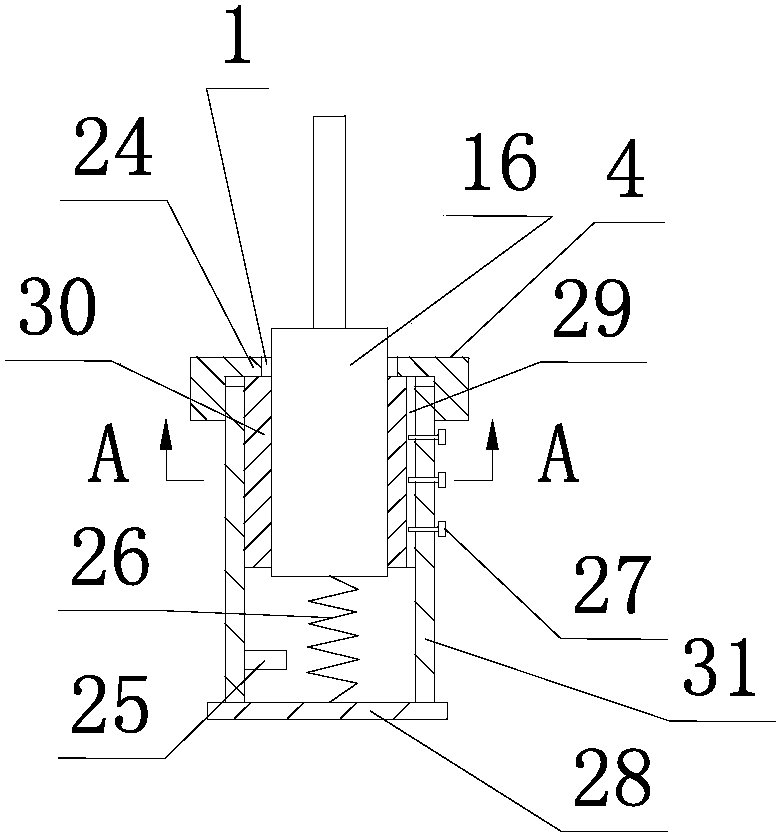

[0039] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 shown

[0040] The bracket for planting bars on the roof of indoor buildings according to the present invention includes a first column, namely the main column 6, a second dowel bar, namely the force transmission vertical bar 13, and a movable connecting rod hinged with the main column 6 and the force transmission vertical bar 13. Connecting cross bar 2, the first dowel bar 12, which is parallel to connecting cross bar 2 and hinged with main column 6 and force transmission vertical bar 13, is the force transmission bar 12, and the part of force transmission bar 12 extending outside the main column 6 constitutes Operating rod 5, main column 6 and power transmission vertical bar 13 are parallel. Here, the main column 6 is strictly speaking that the upper part of the main column 6 doubles as a fixed connecting rod. The connecting cross bar 2 is on the top, and the force transmission cross bar 12 is on th...

Embodiment 2

[0060] Such as Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 shown

[0061] The bracket for drilling the reinforcement on the side of the indoor wall column of the present invention includes the first column, namely the front column 45 and the second column, namely the rear column 41, and the fixed connecting rod vertically fixed to the front column 45 and the rear column 41, i.e. the connecting cross bar 39, The second dowel bar parallel to the connection cross bar 39 is the force transmission cross bar 35 , and the force transmission cross bar 35 is located above the connection cross bar 39 . A first dowel bar, that is, the force transmission vertical bar 37 is hinged with the connecting cross bar 39 and the force transmission cross bar 35, and the part of the force transmission vertical bar 37 extending out of the connection cross bar 39 lower side constitutes the operating rod 40, and the front column 45 is connected to the rear Columns 41 are parallel. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com