Adjustable drill hole positioning device and drill hole positioning method for air inlet flange of exhaust manifold

An exhaust manifold and intake flange technology is applied in the field of an adjustable exhaust manifold intake flange drilling positioning device, which can solve the problems of increased processing cost, low qualification rate, high price, etc., and can ensure drilling The effect of hole quality, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

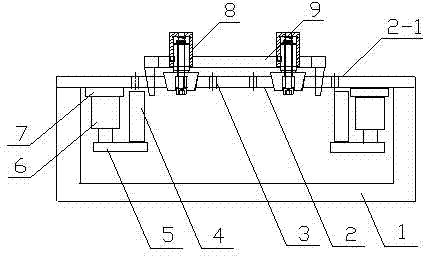

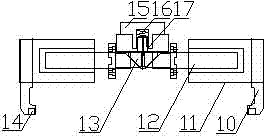

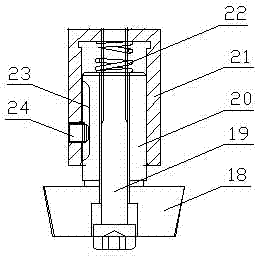

[0020] see figure 1 , figure 2 , image 3 , the adjustable exhaust manifold intake flange drilling positioning device of the present invention has a clamp body 1, and the clamp body 1 is provided with a positioning plane 2-1 at the bottom of the top plate 2 for positioning the reference plane of the exhaust manifold. Z-axis positioning on the exhaust manifold positioning reference plane - the end face of the intake flange. Two sets of single-hole positioning molds 8, a set of double-hole positioning molds 9, and through holes respectively matched with the single-hole positioning molds 8 and the double-hole positioning molds 9 are arranged on the top plate 2, and are provided with drill guides. The drilling template hole 3. At least two sets of workpiece clamping mechanisms are arranged below the positioning drilling template 2 for clamping and fixing the workpiece to be drilled.

[0021] The double-hole positioning mold 9 is used for the X-axis positioning of the exhaust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com