Wheel drilling machine

A wheeled, drilling rig technology, applied in drill pipes, drill pipes, drilling equipment, etc., can solve the problems of high labor consumption, long drilling rig positioning time, and unsuitable construction in harsh road conditions, so as to ensure drilling quality, enhance accuracy and speed. Positioning performance, manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

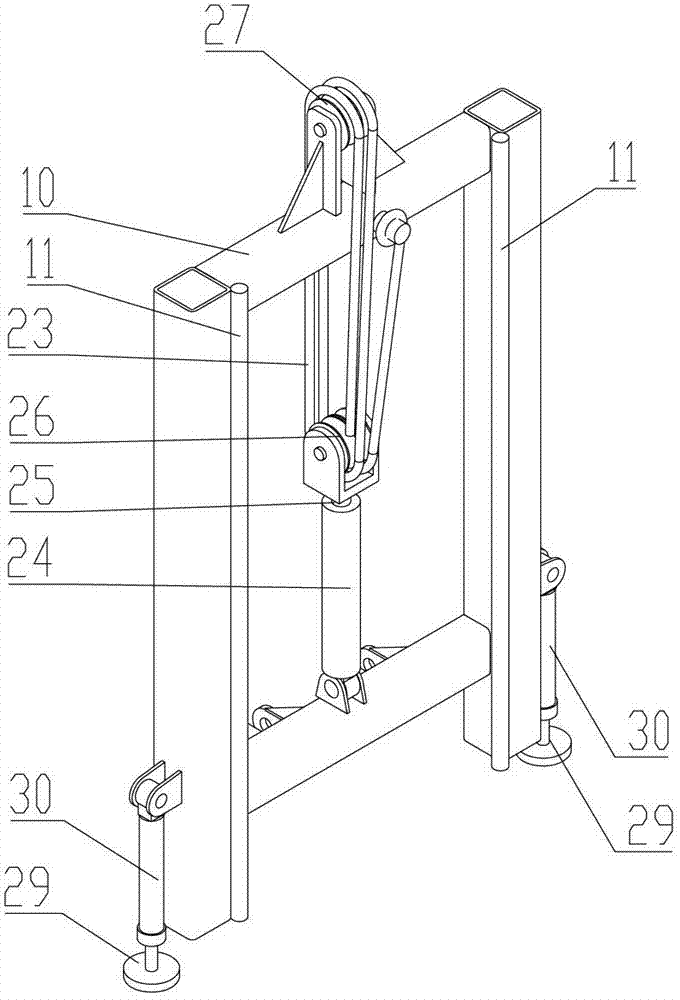

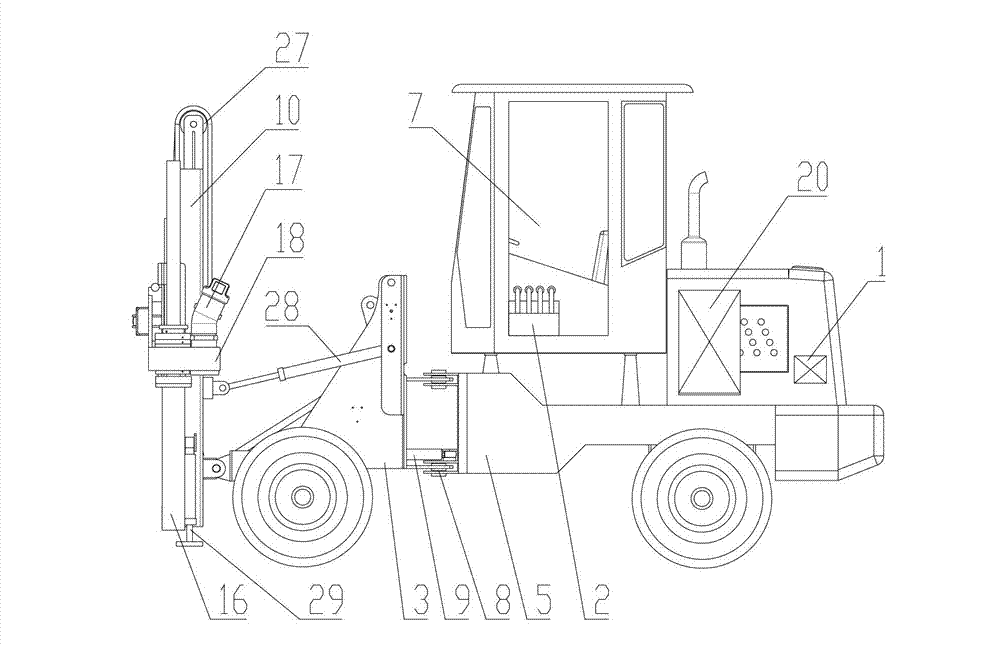

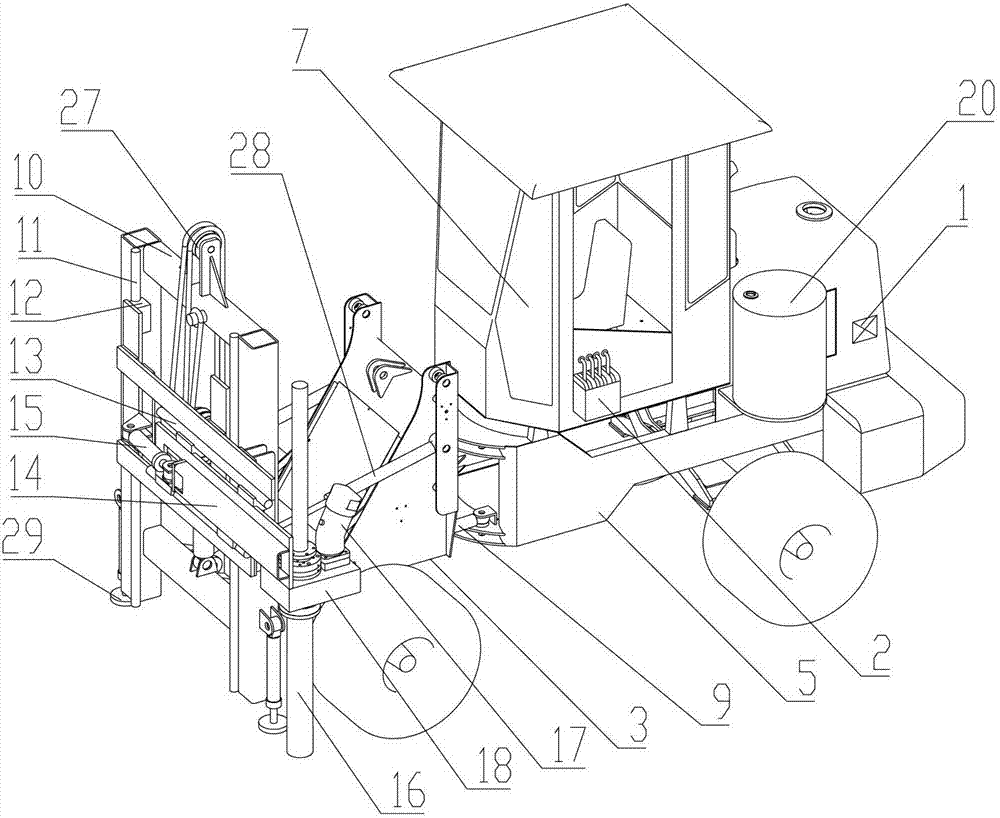

[0035] The present invention will be described in detail below in conjunction with accompanying drawing, as Figures 1 to 4 As shown: the wheeled drilling rig of this embodiment includes a wheeled traveling mechanism, a drill pipe assembly, a drilling rig loading mechanism and a hydraulic control mechanism. The hydraulic control mechanism includes an oil pump 1 and a multi-way control valve 2. The wheeled traveling mechanism The mechanism includes the front frame 3, the front axle 4 arranged on the frame, the frame 5, the rear axle 6 arranged on the frame and the driver's cab 7, and the frame 3 and the frame 5 pass through The hinge pin 8 is hinged, and the hinge pin 8 of the front frame and the afternoon frame is provided with a steering cylinder 9 connected with a hydraulic control mechanism for controlling the swing of the front frame around the hinge, and the steering cylinder 9 The two ends are respectively hinged on the front frame 3 and the afternoon frame 5; Two steer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com