Application method for clamping device of electric cabinet

A technology of clamping device and electrical cabinet, which is applied in positioning device, clamping, supporting and other directions, can solve the problems of high cost of clamping device, easy vibration or sliding, deviation of drilling direction, etc., and achieves convenient operation and application. Wide range, stable drilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

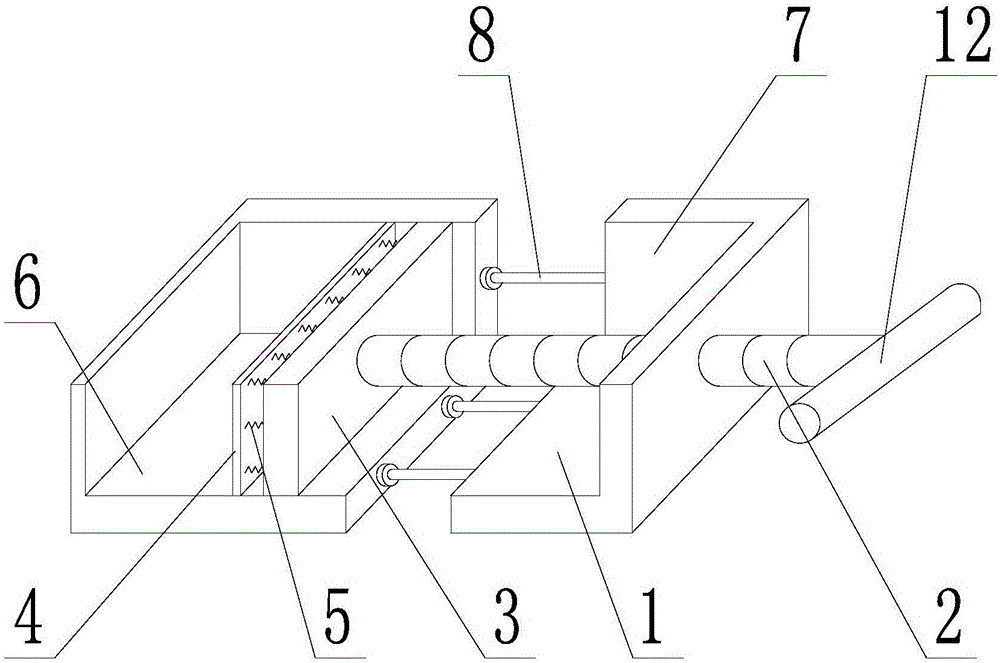

[0025] Such as Figure 1 ~ Figure 2 As shown, the method of using the clamping device suitable for electrical cabinets includes the following steps:

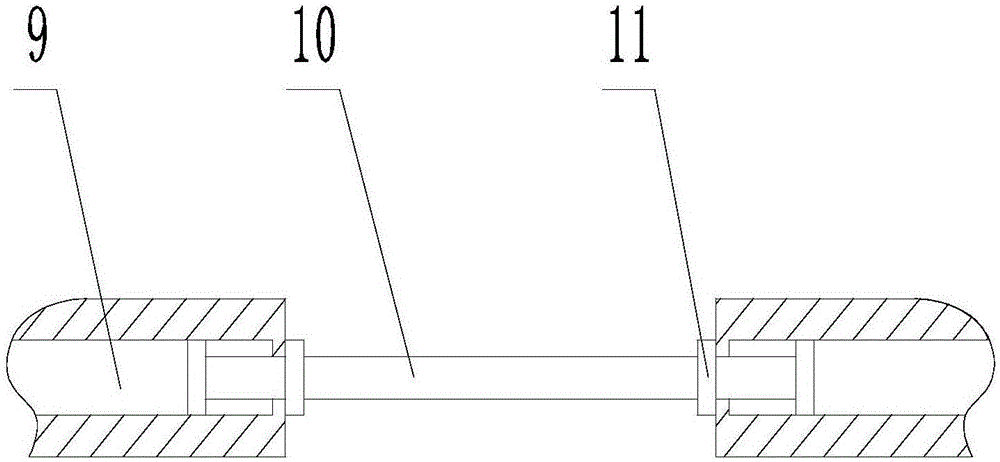

[0026] S1: Place the base 1 on the workbench or the ground, a screw 2 is provided through one side of the base 1, and a threaded hole matching the thread of the screw 2 is provided on the base 1, and the base 1 includes a bottom plate 6 and a side plate 7. Both the base plate 6 and the side plate 7 are provided with a telescopic mechanism 8. The telescopic mechanism 8 includes a guide groove 9 and a telescopic rod 10. The telescopic rod 10 is located in the guide groove 9, and the telescopic rod 10 can move along the guide groove 9. The telescopic rod 10 10. The size of both ends is larger than the opening size of the guide groove 9. Pull the telescopic rod out of the guide groove to increase the size of the base, which is suitable for larger electrical cabinets; push the telescopic rod into the guide groove to reduce the size o...

Embodiment 2

[0034] The difference between this embodiment and Embodiment 1 is that the end of the screw rod 2 outside the base 1 is provided with a driving device (not shown in the figure), and the driving device controls the rotation direction and speed of the screw rod, so that the pressing plate 3 and damping plate 4 advance or retreat along the screw rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com