Drilling tool for airplane sliding rail

A slide rail system and tooling technology, which is applied in the direction of drilling dies for workpieces, etc., can solve the problems of riveting assembly tasks that cannot be completed according to the production plan, cannot meet the requirements of product interchangeability, and affect the delivery of aircraft as planned. The effect of riveting assembly cycle, ensuring drilling quality and avoiding drilling damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

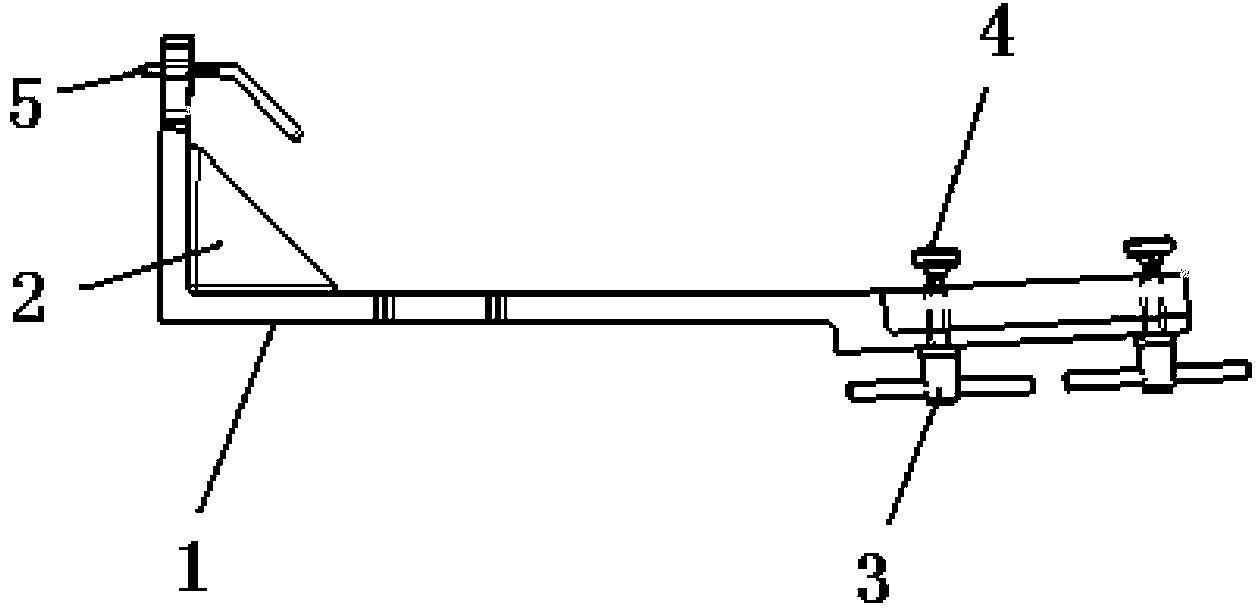

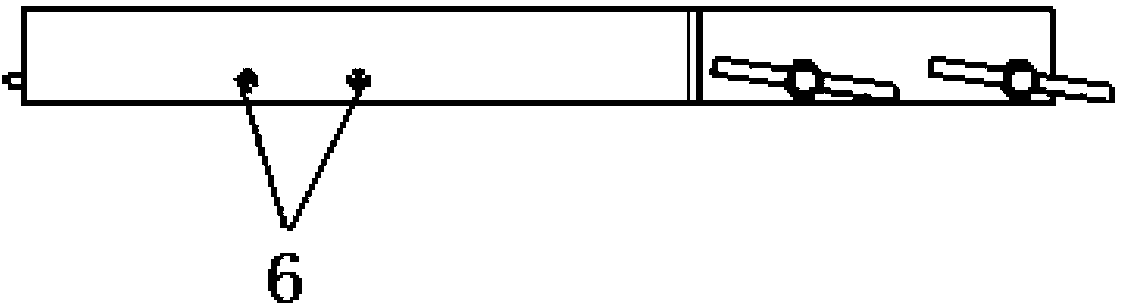

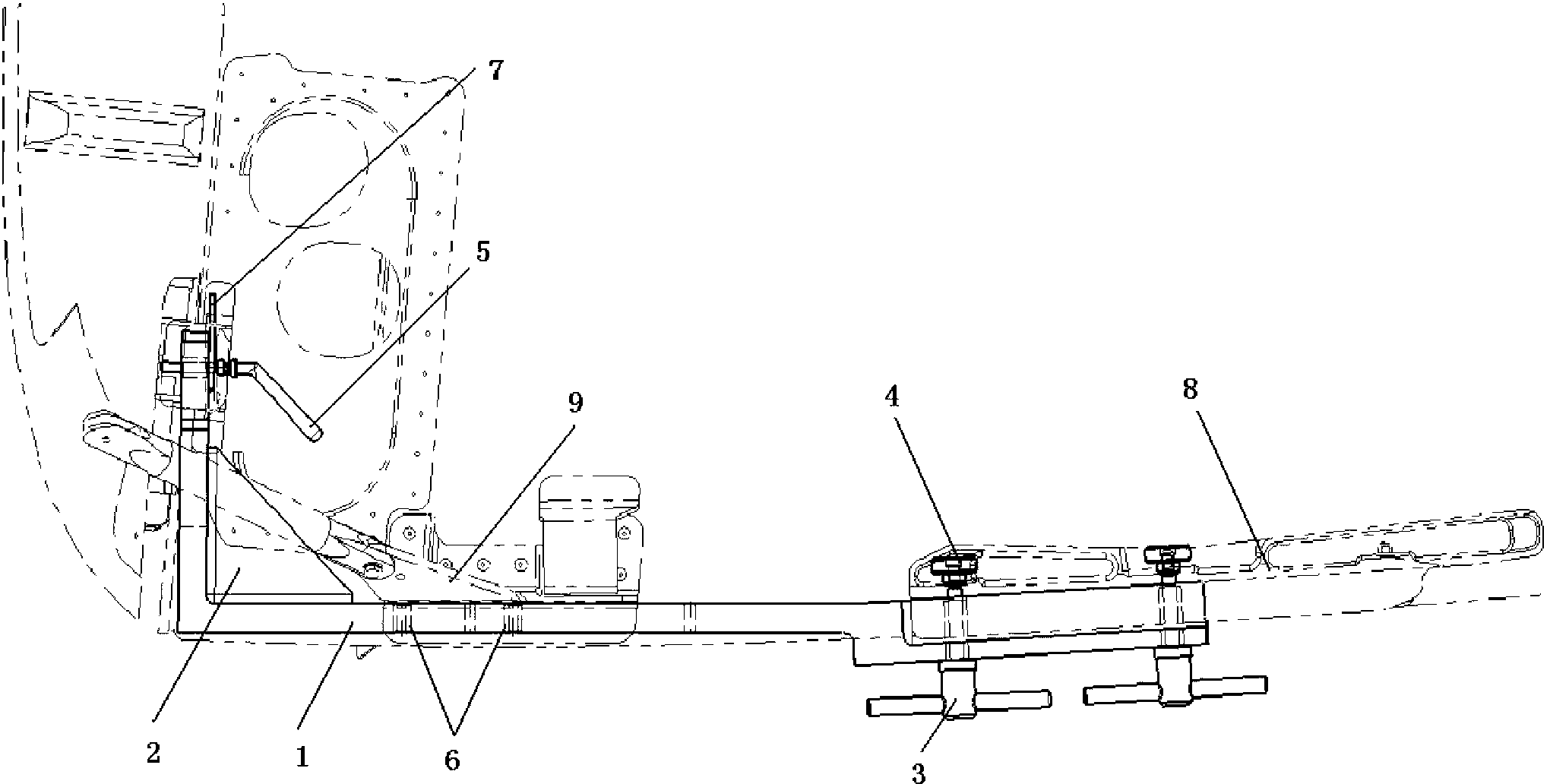

[0011] See attached Figure 1~2 As shown, this kind of aircraft slide rail hole-making tool is characterized in that: the tool includes an L-shaped drilling template 1, and the bending part of the L-shaped drilling template 1 is fixed and strengthened with a reinforcing angle plate 2, and the inner part of the drilling template 1 The surface fits the side profile of the front bracket 7 of the slide rail and the rear bracket 8 of the slide rail. A bent handle pin 5 is installed on the front end of the drill template 1 to connect and locate with the preset positioning hole on the front bracket 7 of the slide rail. The rear of the drill template 1 Two positioning bolts 3 and knurled nuts 4 are provided at the end to connect and position with the two preset positioning holes on the rear bracket 8 of the slide rail. Two drill slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com