Patents

Literature

40results about How to "Meet the requirements of interchangeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

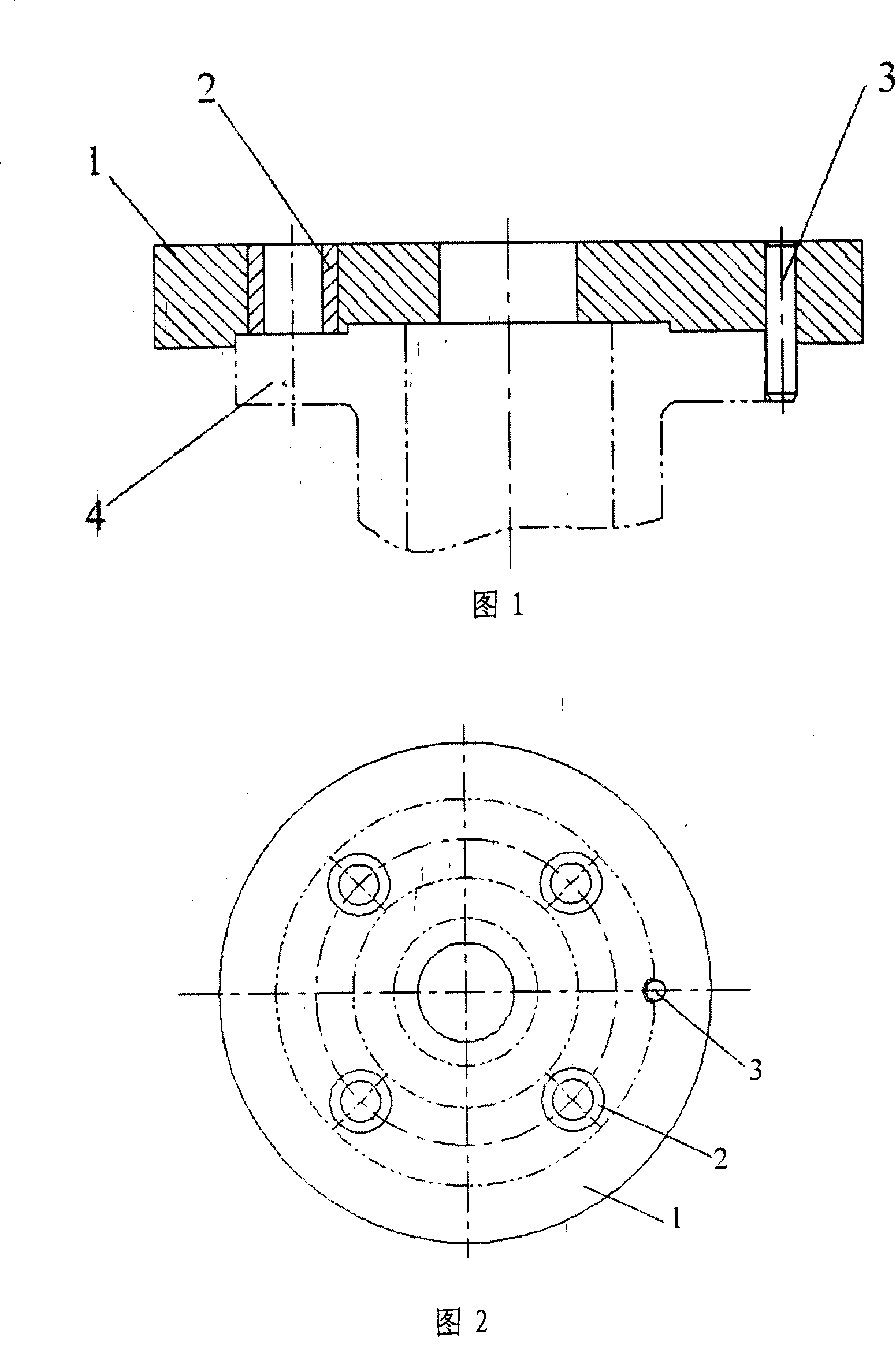

Flange quick-changing drill jig

The invention provides a flange quick-change drill plate and consists of a metal disk component. The metal disk component is provided with a plurality of through holes inside, axial direction of any through hole is parallel to that of the metal disk component, a drill bush is fixedly arranged in any through hole, any drill bush is a cylinder tubular component, and at least one positioning pin hole is arranged in the metal disk component. A positioning pin is arranged in the positioning hole. An arc-shaped nick is casted on the rough of an awaiting flange, the metal disk component is arranged on the end surface of the flange when in processing, the positioning pin is arranged in the arc-shaped nick of the flange rough, a spigot of the metal disk component matches with the spigot of the flange rough, and then drilling of the flange rough can be conducted with the drill bush. The invention has simple operation and easy use and can meet the requirement of large scale production, moreover, bias of processed hole site is less than 1mm and can meet the requirement of interchangeability.

Owner:SHANGHAI EAST PUMP(GRP) CO LTD

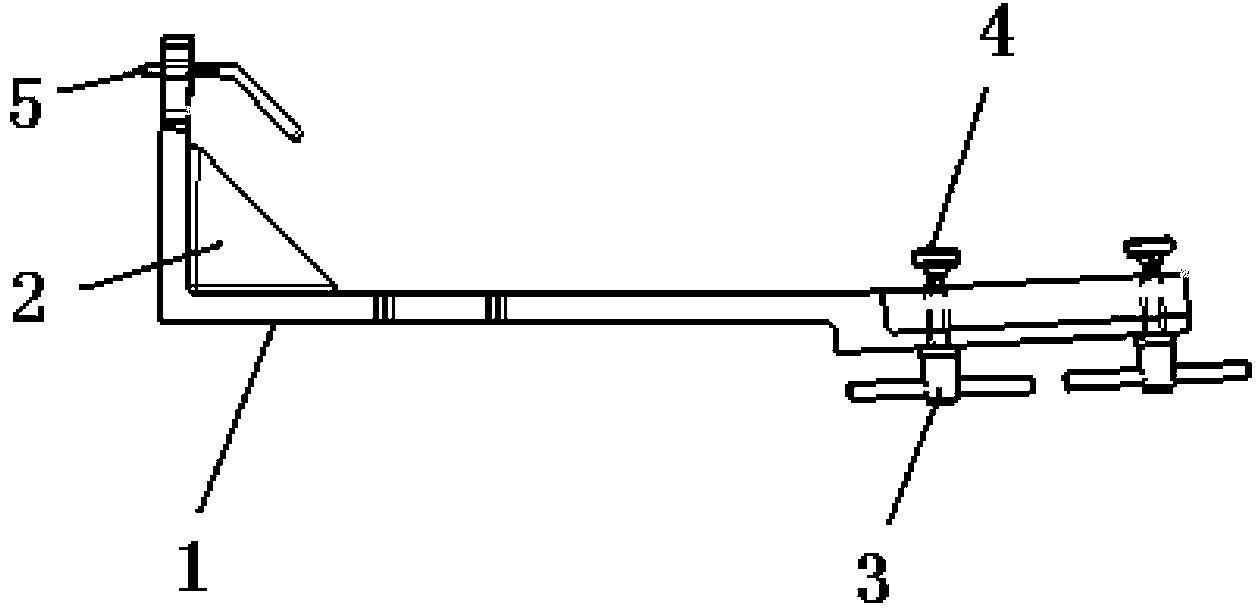

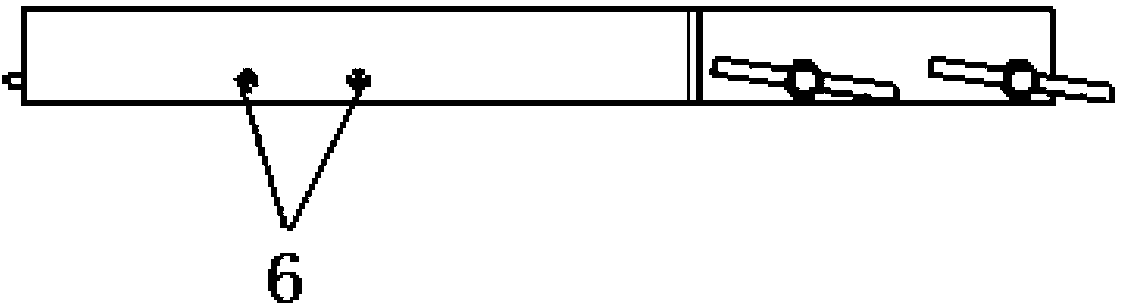

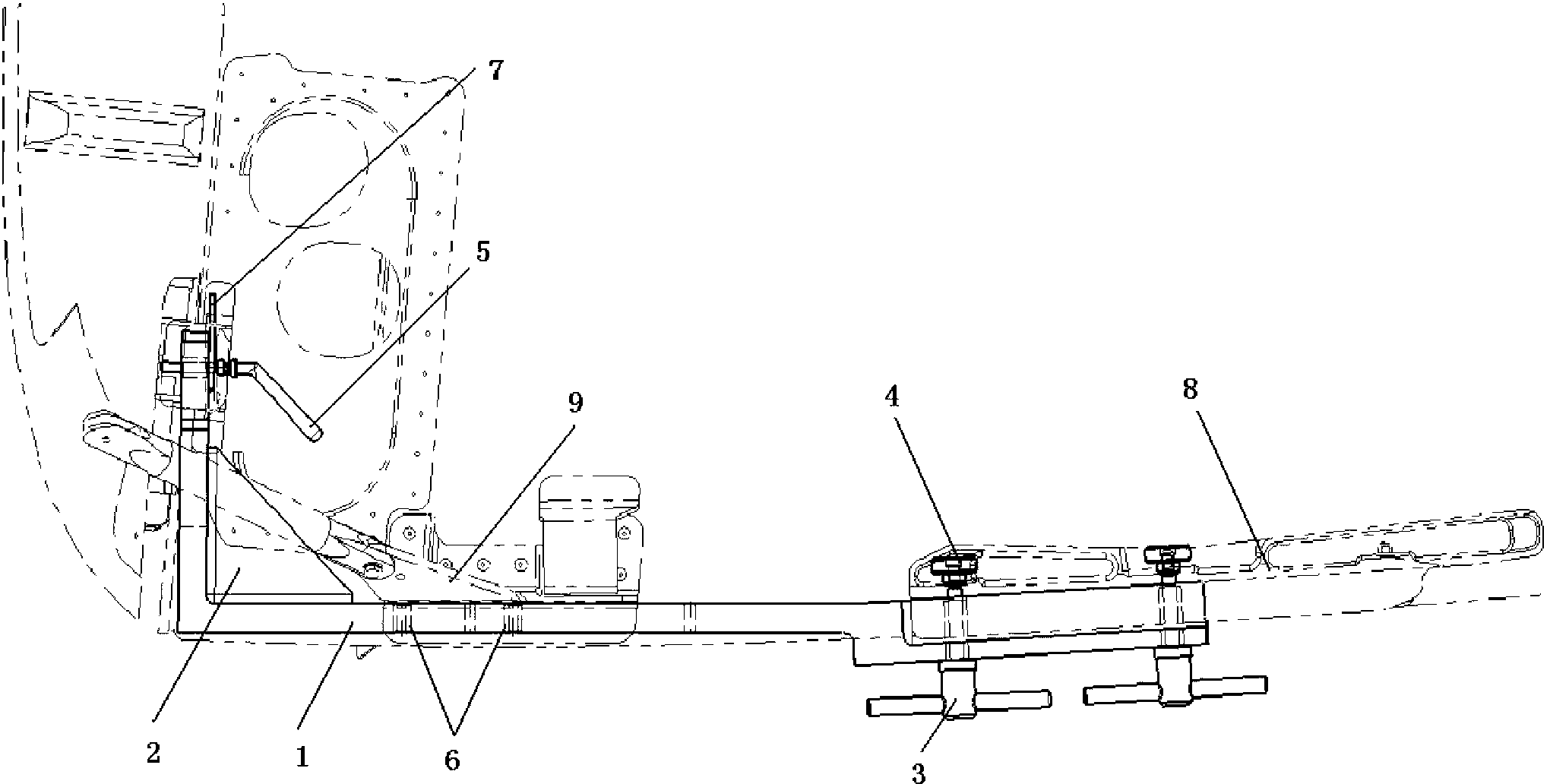

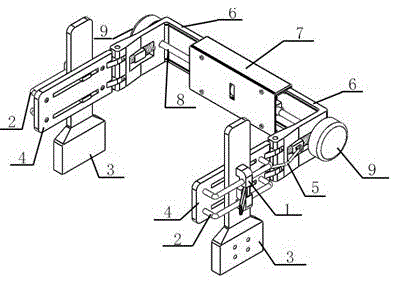

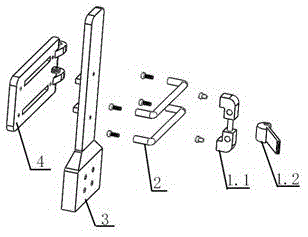

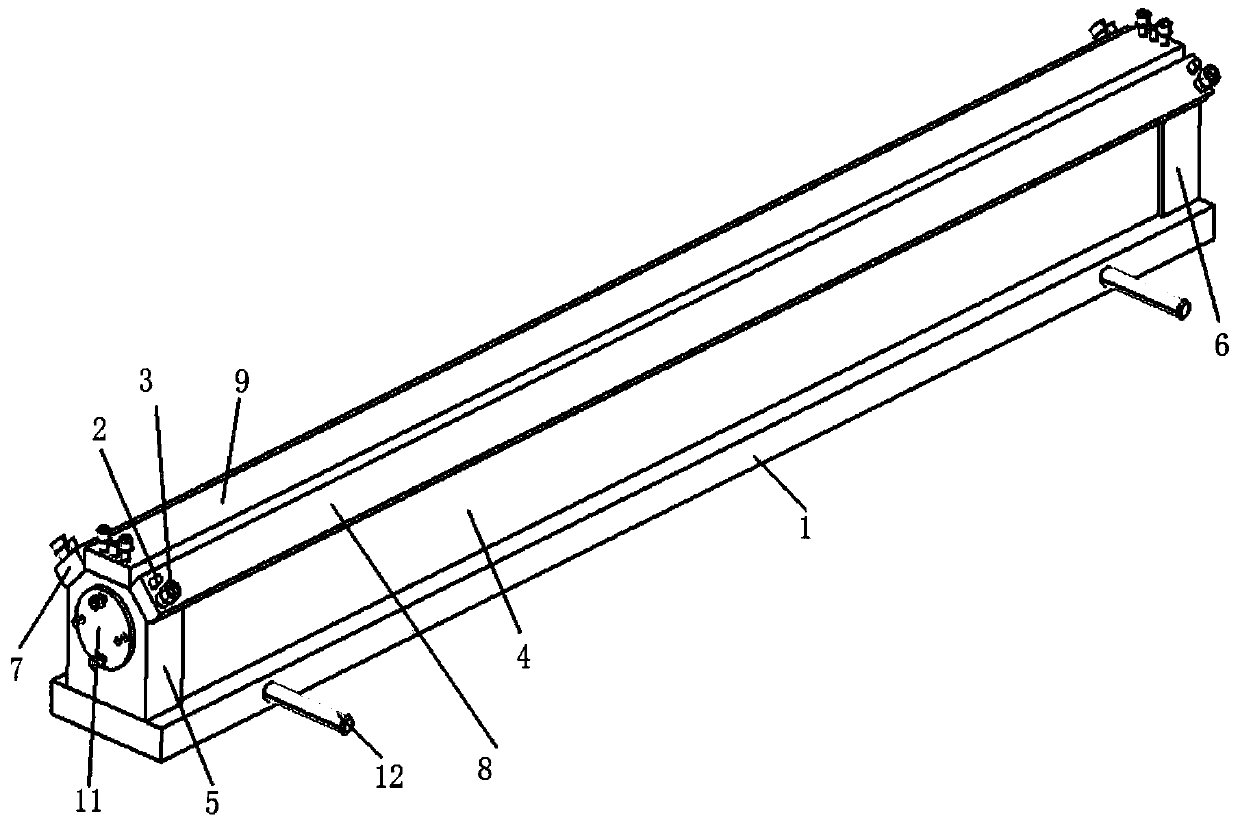

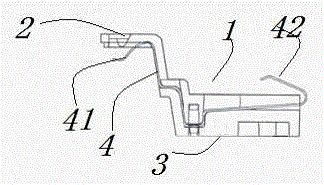

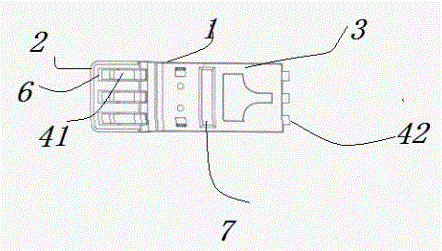

Drilling tool for airplane sliding rail

InactiveCN103192118AEasy to install holesAvoid drillingDrill jigsStructural engineeringDrill bushing

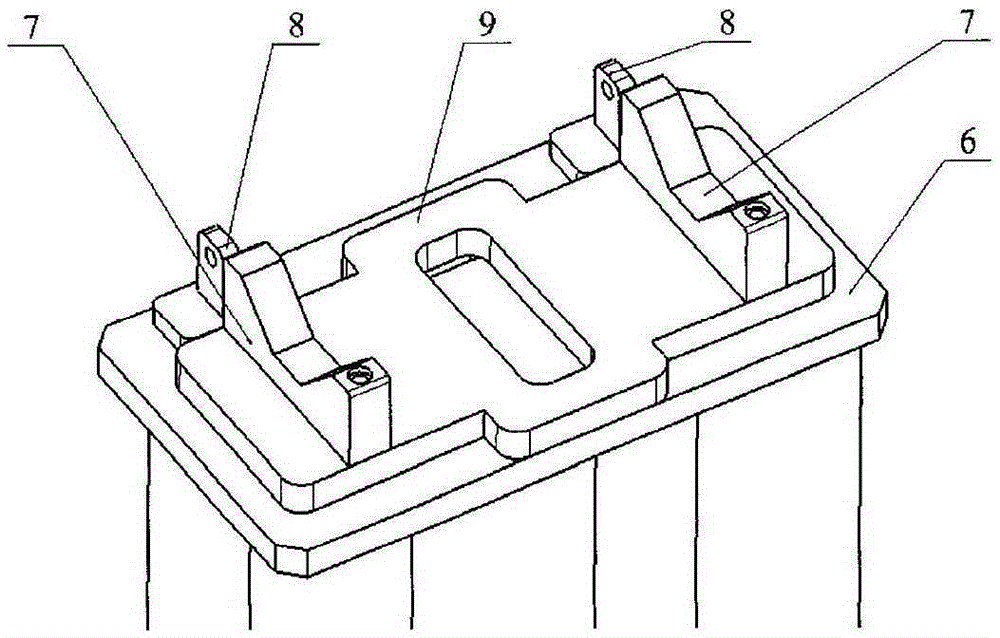

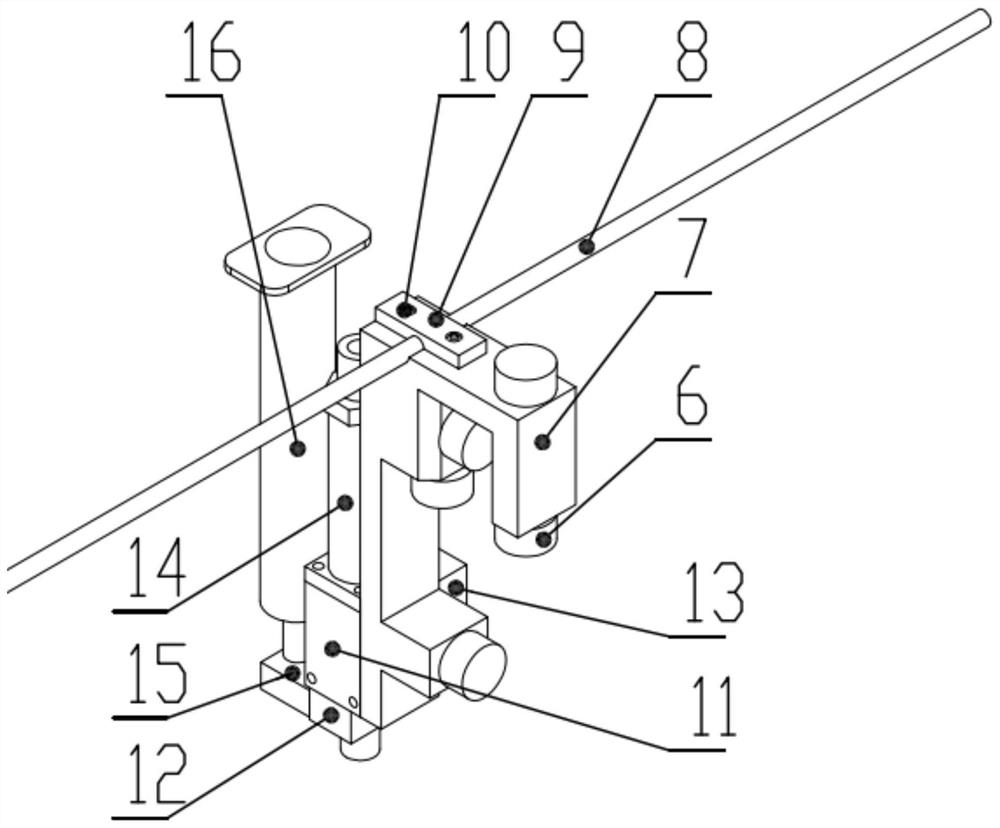

The invention relates to a drilling tool for an airplane sliding rail. The drilling tool comprises an L-shaped drill template (1), wherein a bending part of the L-shaped drill template (1) is fixed and reinforced by using a reinforcing angle plate (2), the inner surface of the drill template (1) is clung to the exterior of the side surfaces of a sliding rail front bracket (7) and a sliding rail rear bracket (8), a bent handle pin (5) is installed at the front end of the drill template (1) and connected with a precast positioning hole in the sliding rail front bracket (7) for positioning, two positioning bolts (3) and knurled nuts (4) are installed at the rear end of the drill template (1) and connected with two precast positioning holes in the sliding rail rear bracket (8) for positioning, two drill bushing holes (6) are formed in the middle of the drill template (1), the positions of the two drill bushing holes (6) correspond to those of two holes to be machined in a sliding rail middle bracket (9), and the diameter of the two drill bushing holes (6) is 5 plus or minus 0.2mm. The drilling tool facilitates drilling in the installation of the airplane sliding rail, avoids deviation occurring in pre-installation of a finished product of the sliding rail, ensures the drilling quality, satisfies the requirement on the interchangeability of the sliding rail, and improves the percent of pass of the product.

Owner:HARBIN

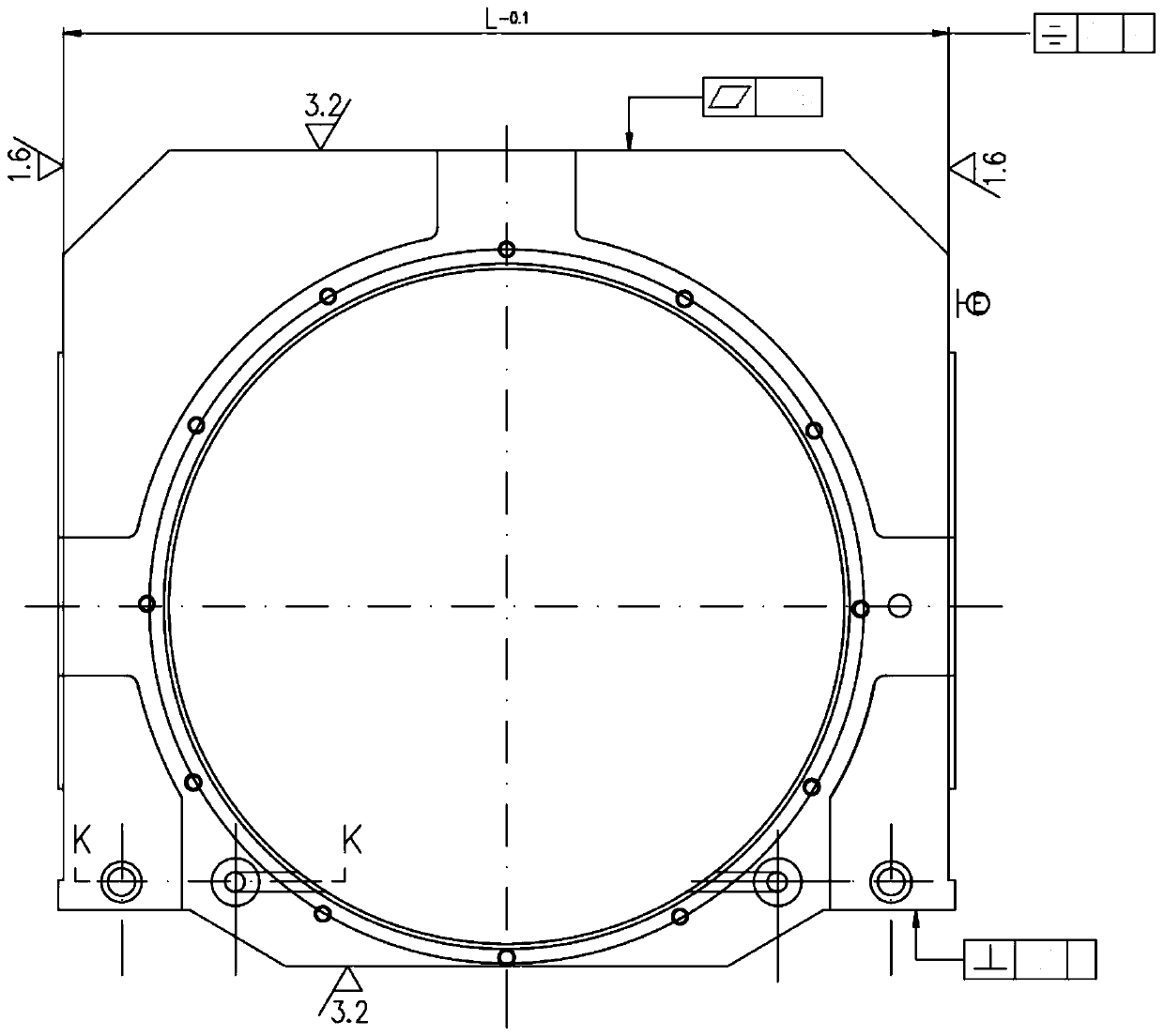

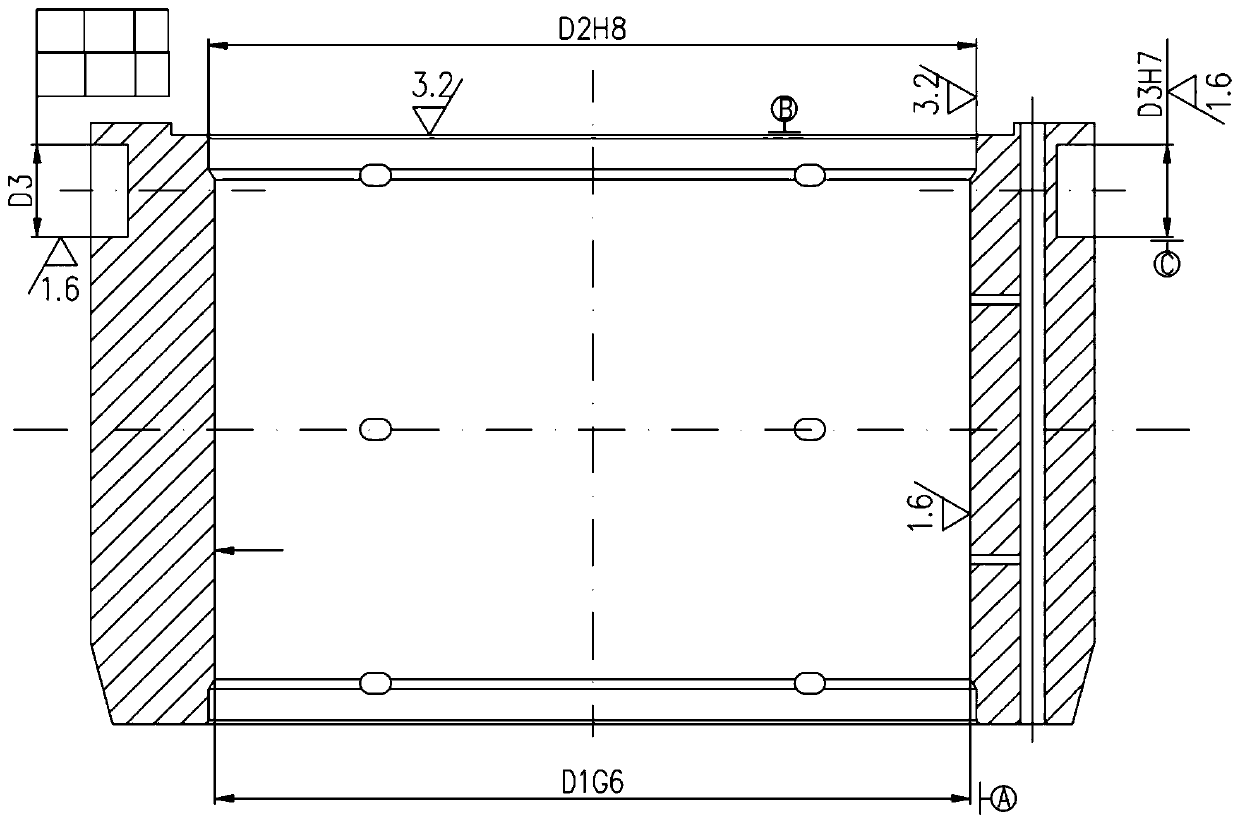

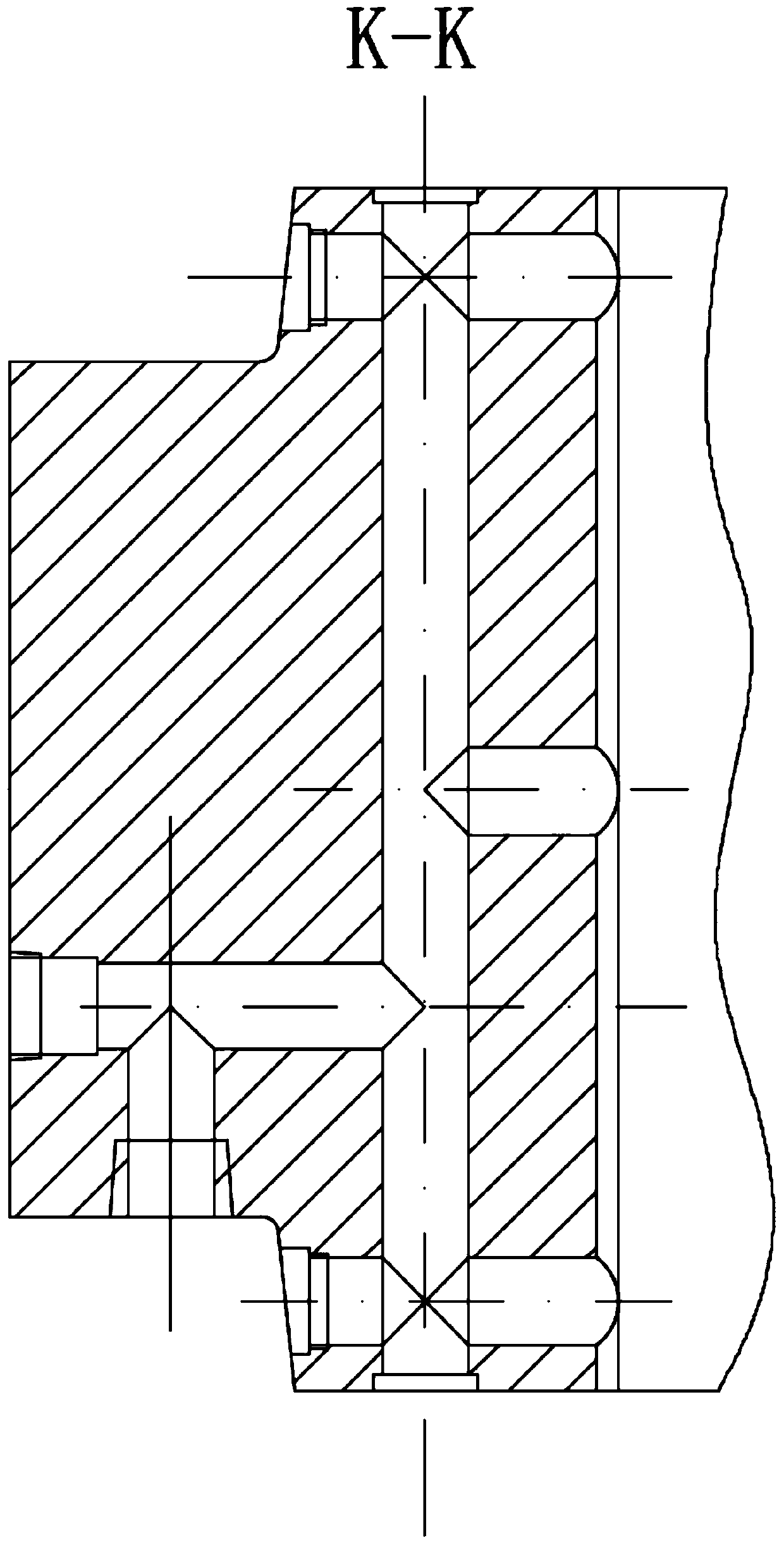

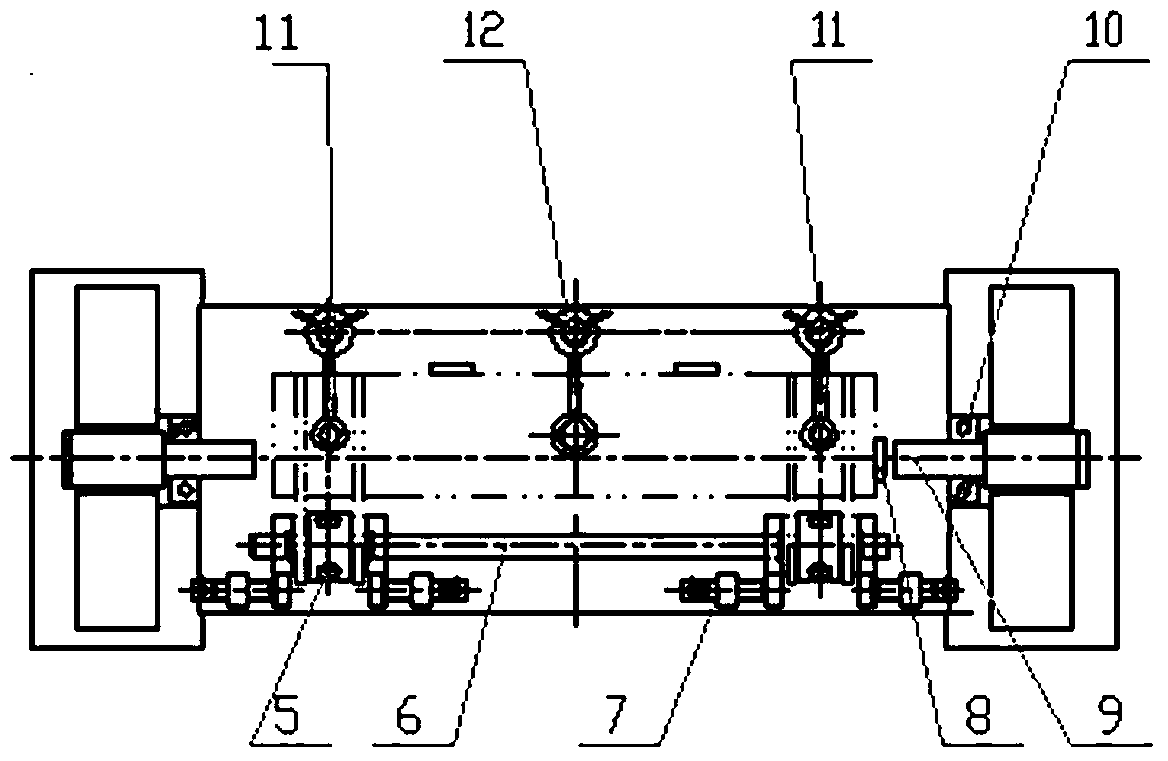

Rolling mill bearing base and manufacturing method thereof

ActiveCN109731916AMeet quick replacement requirementsAxial positioning is accurateMetal rolling stand detailsFurnace typesSurface roughnessSlide plate

The invention discloses a rolling mill bearing base and a manufacturing method thereof. The rolling mill bearing base is forged and processed from high-quality alloy steel, and is mounted at the two ends of a supporting roller of a symmetrical structure on a large rolling mill; the sliding surface which is in contact with a rolling mill memorial gate is equipped with a copper slide plate; precision of a bearing hole is G6, surface roughness of the bearing hole is Ra1.6 and cylindricity of the bearing hole is 0.03mm; precision of a bearing end cover matching hole is H8, surface roughness of thebearing end cover matching hole is Ra3.2, surface roughness of sliding surfaces at the two sides is Ra1.6, degree of symmetry on the bearing hole is 0.1 mm, flatness of an upper surface is 0.05mm, perpendicularity, to the sliding surfaces, of a lower surface is 0.2 mm, the two sliding surfaces are symmetrically equipped with dowel pin holes, precision of the dowel pin holes is H7, surface roughness of the dowel pin holes is Ra1.6, degree of symmetry on the bearing hole is 0.1 mm, and center perpendicularity to the bearing hole is 0.1 mm. An intensive lubricating system is adopted, and a ratioof hole depth to hole diameter of an oil inlet and outlet is 20 or higher. The rolling mill bearing base can meet the requirements of quickly replacing and interchanging a supporting roller, is accurate in positioning, is good in cooling and lubricating effect, is high in precision, reduces rolling mill faults, and guarantees the processing quality.

Owner:武汉钢铁有限公司

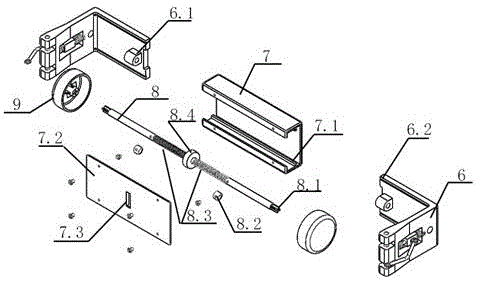

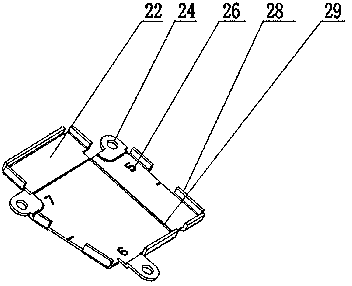

Adjusting device used for fixing wearable lower-limb exoskeleton robot and human body waist

InactiveCN105105896AReduce displacementEasy to fixInvalid friendly devicesExoskeleton robotEngineering

The invention discloses an adjusting device used for fixing a wearable lower-limb exoskeleton robot and the human body waist. The adjusting device is composed of two same adjusting structures symmetric in a left-and-right mode. The two same adjusting structures are connected together through a width fixing plate. One of the adjusting structures is composed of eccentric clamps, two smooth rod pieces, thickness adjusting plates, waist fixing plates, connecting-rod sliding-block mechanisms, width adjusting plates, a stud and runners. By means of the adjusting device, the problems that in existing exoskeleton-robot and human-body-waist fixing, the width and the thickness can not be continuously adjusted, operation is complex, the interchangeability requirement can not be met, and the human bodies in different body types can not be well adapted are effectively solved.

Owner:WUHAN UNIV

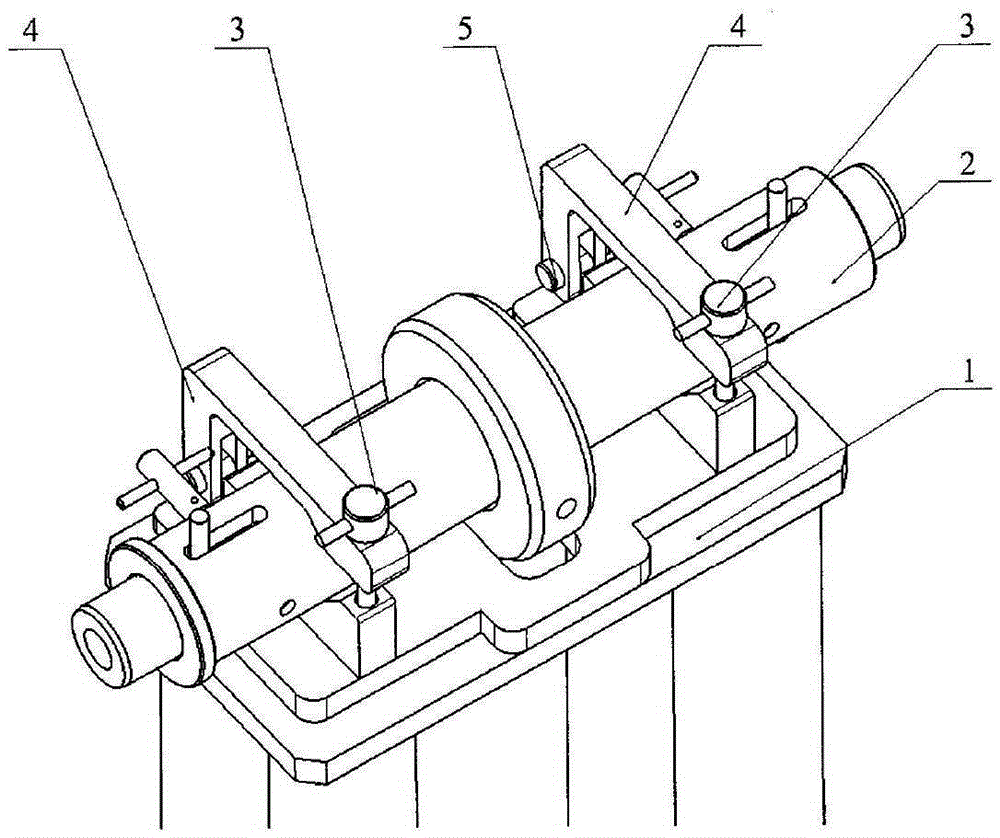

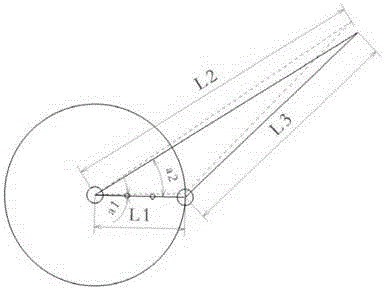

Mechanism and method for quickly positioning airplane components

ActiveCN105252314AShorten the timeReduce manufacturing costsWork holdersPositioning apparatusProduction linePositioning system

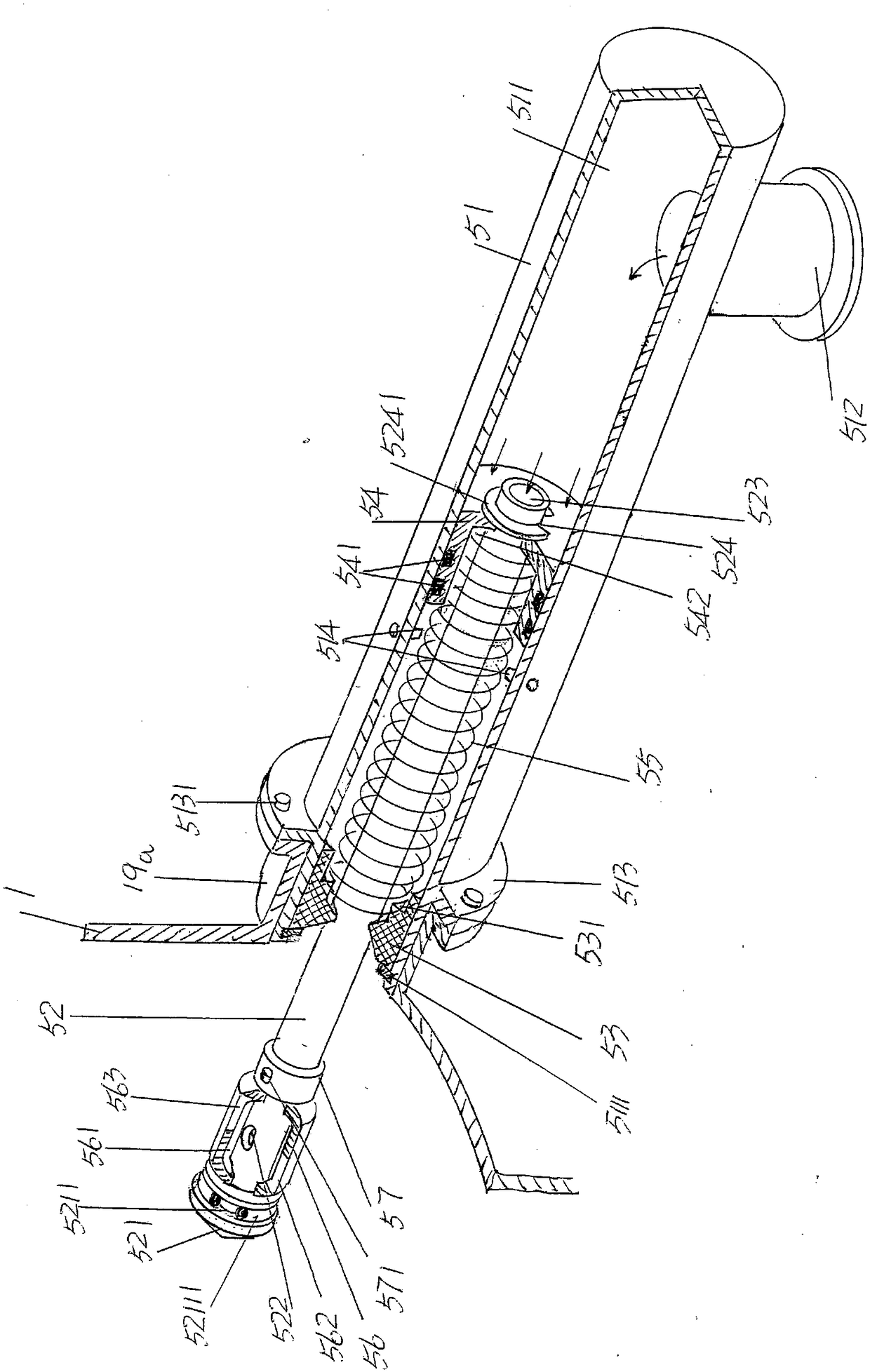

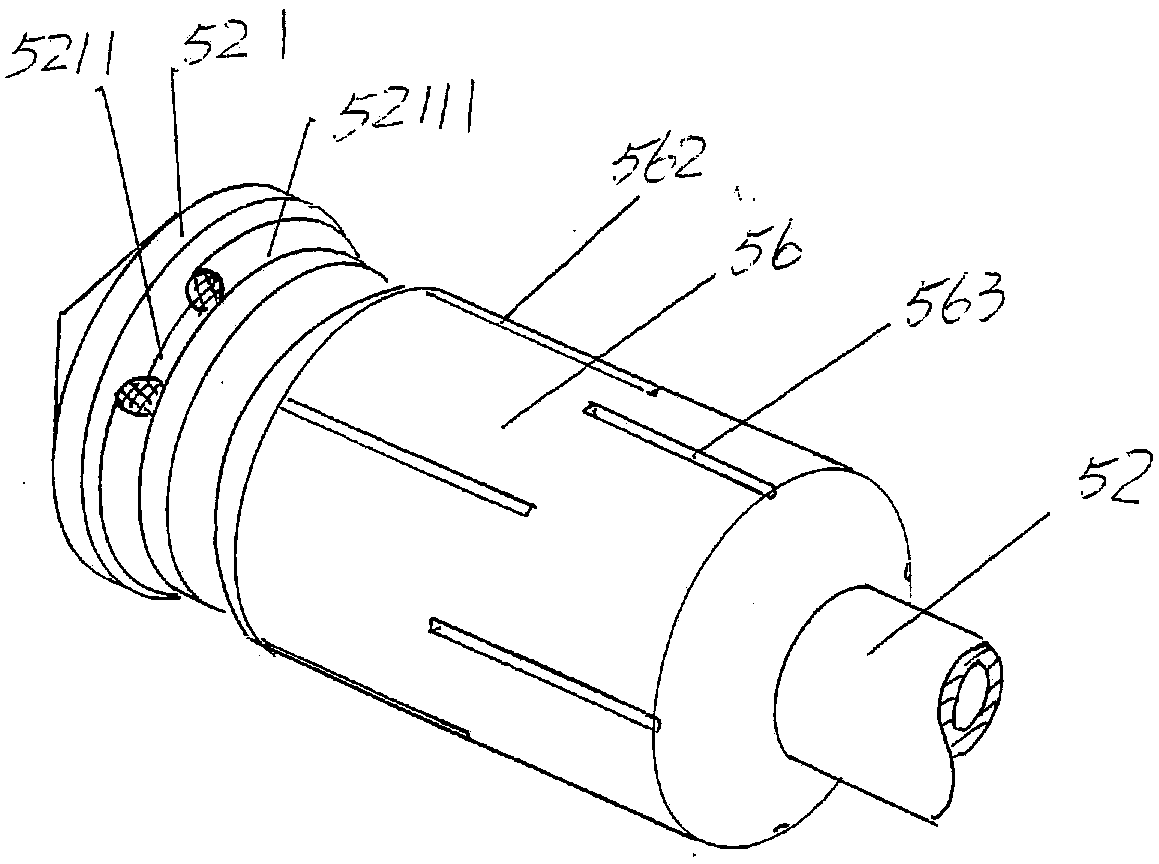

The invention discloses a mechanism for quickly positioning airplane components. The mechanism is provided with a guiding and positioning mechanism and a limited seat which cooperates with the guiding and positioning mechanism, wherein the guiding and positioning mechanism is provided with a positioning shaft; the positioning shaft is cylindrical; connecting shafts are respectively arranged at two ends, in the positioning shaft, and are connected with holes in the airplane components; an axial limited block is arranged on the positioning shaft, and is arranged in the middle of the positioning shaft in a sleeving manner; the limited seat is provided with a base; an axial positioning groove is formed in the base, and cooperates with the axial limited seat so as to perform axial positioning on the guiding and positioning mechanism. Through the adoption of the mechanism disclosed by the invention, the purposes that the airplane components are quickly positioned and connected when being mounted at different work positions or being remounted are realized; the positioning flexibility of the airplane components and the mounting flexibility of the airplane components are realized; products are adapted to being mounted, dismounted and transferred at different work positions on a production line; the production preparation cycle is shortened; the cost for researching and manufacturing airplanes is reduced.

Owner:SHENYANG AIRCRAFT CORP

an extraction tank

ActiveCN106582059BReduce the degree of impactReduce stressHollow article cleaningSolid solvent extractionHot zoneBiochemical engineering

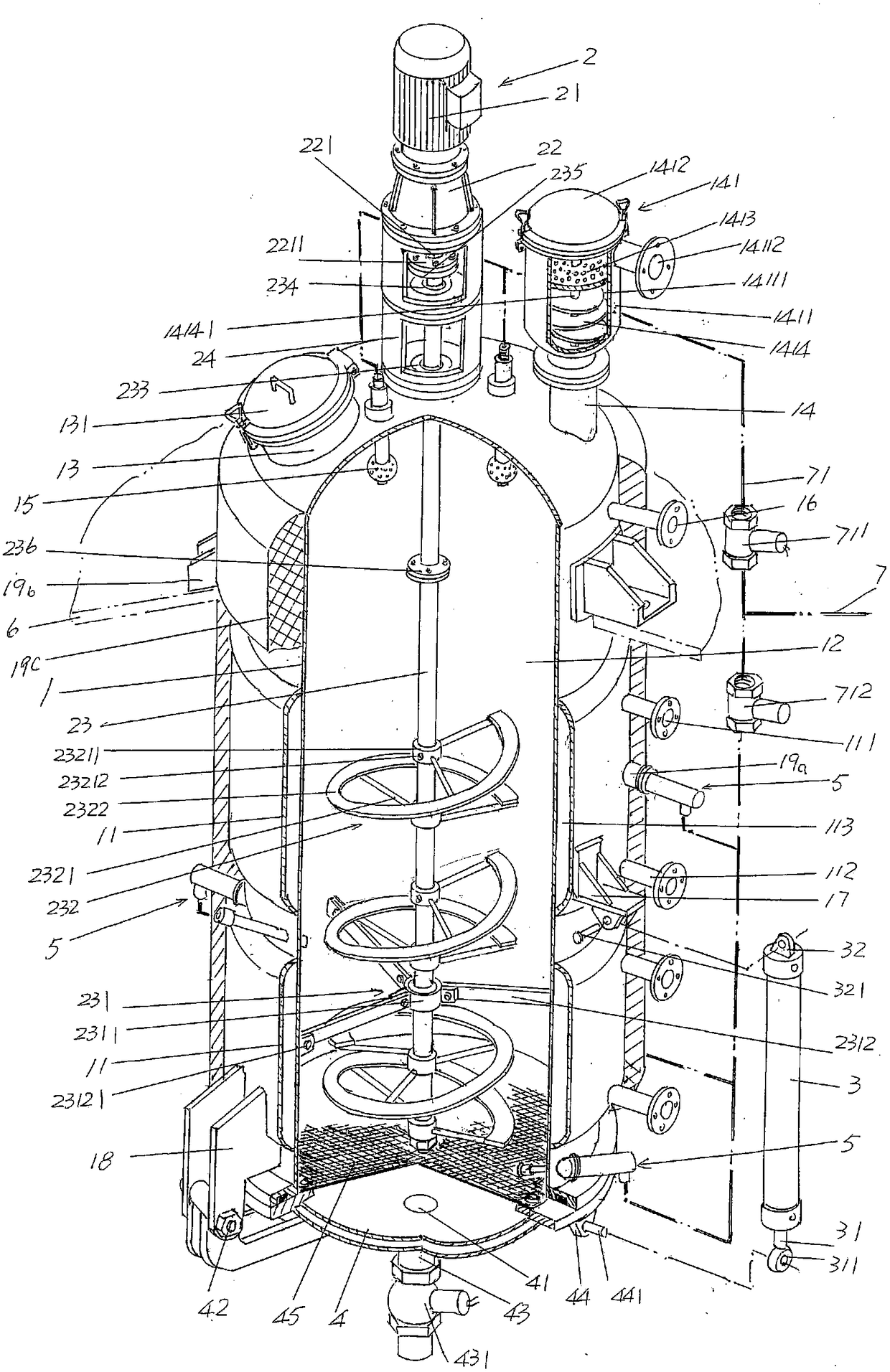

Disclosed is an extracting tank. The extracting tank comprises a tank body, a stirring mechanism, and a plurality of side-placed rinsing mechanisms, wherein a heating spacer bush is arranged at the outer wall of the tank body, a heating medium leading-in connector and a heating medium leading-out connector are arranged on the heating spacer bush, and the top of the tank body is provided with a feeding port and a demister connector; a stirring motor coordinates with a stirring decelerator, a stirring shaft is located in a tank body cavity, a stirring shaft support is fixed on the cavity wall of the tank body cavity, and the shaft body of the stirring shaft is provided with a stirring blade; an acting cylinder is arranged on the tank body, one side of a slag discharging gate is hinged to the tank body, the other side of the slag discharging gate is connected with the acting cylinder, and the center is provided with an extracting solution leading-out port; the side-placed rinsing mechanisms are arranged on the side wall of the tank body and stretch into the tank body cavity. The extracting tank is characterized in that the stirring blade is composed of a helical band supporting frame and a helical band, the helical band supporting frame is fixed to the stirring shaft, and the helical band is fixed on the helical band supporting frame and maintains certain distance from the stirring shaft and the cavity wall of the tank body cavity. In this way, requirements of interchanging between a cold zone and a hot zone are satisfied, and an effect of uniform temperature of a material is guaranteed; meanwhile, influence of moment of force on the stirring shaft and stress degree of the stirring shaft are lowered, and thus appearance of deformation can be avoided; in addition, the rinsing effect of the extracting tank is good.

Owner:JIANGSU SHAJIABANG CHEM EQUIP

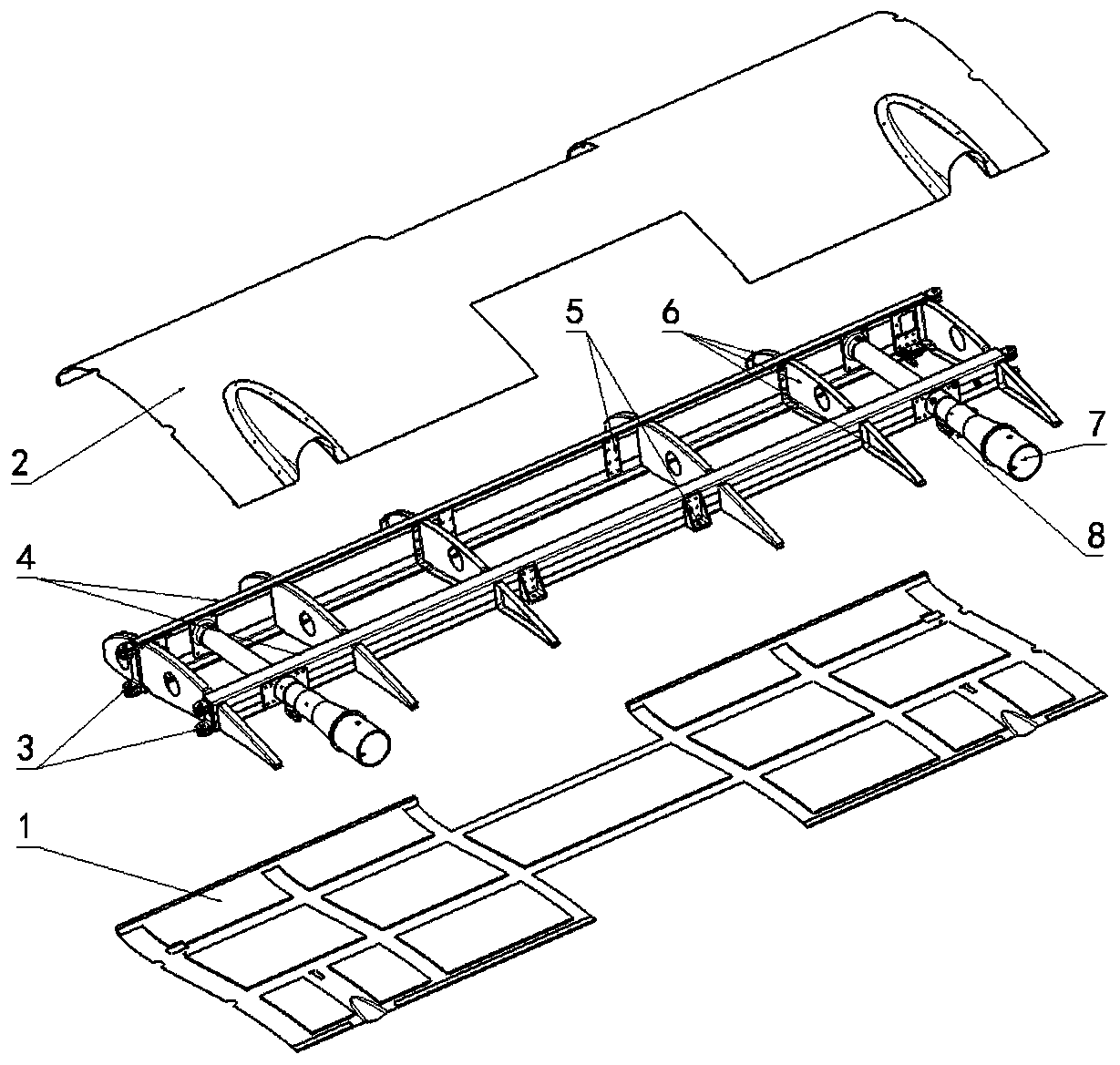

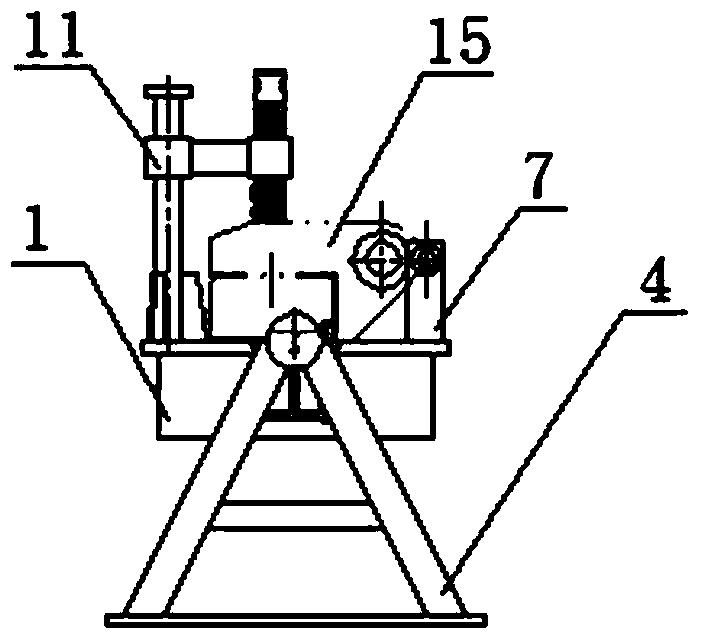

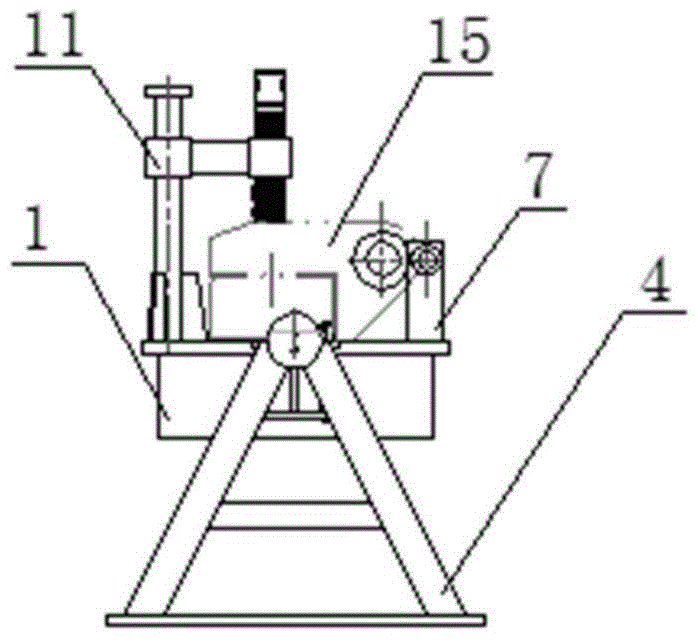

Middle wing part gluing and folding tool for small and medium-sized unmanned aerial vehicles

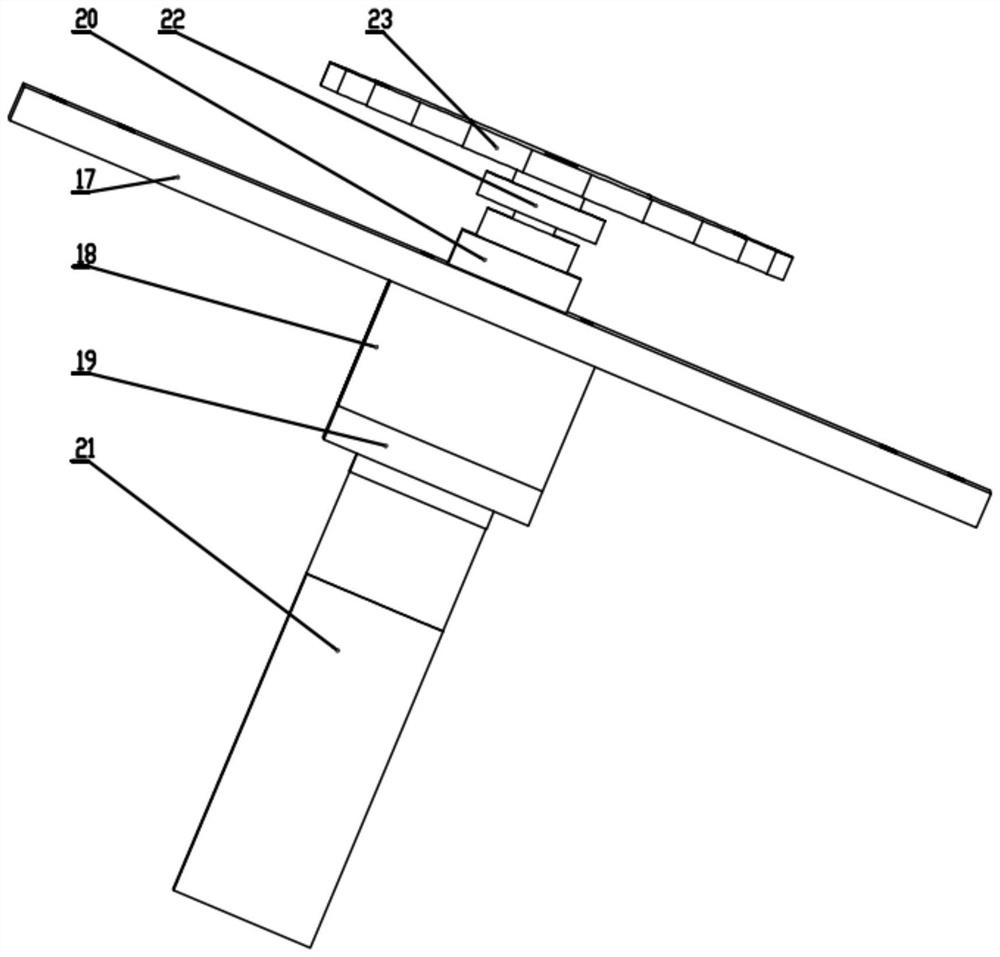

PendingCN111483609AMeet the requirements of interchangeabilityEasy to separateAircraft assemblyUncrewed vehicleFront edge

The invention discloses a middle wing part gluing and folding tool for small and medium-sized unmanned aerial vehicles. The middle wing part gluing and folding tool consists of a rotating support, a base, a pressing frame and positioners mounted on the base. The rotating support is used for supporting the rotating base and the pressing frame, and combination and separation of the rotating supportand the base can be rapidly achieved through insertion and extraction of the pin shaft. The base is used for supporting the lower plate and positioning and installing the positioners. The pressing frame is used for positioning the upper plate and measuring the gap, and uniformly applying cementing pressure. The horizontal measuring point positioner is used for drilling holes in the front edge andthe rear edge of the middle wing part and positioning horizontal measuring points. The middle wing front-back connector positioner is used for positioning a middle wing front-back connector and servesas a connector hole finish machining platform to eliminate assembly stress. According to the middle wing part gluing and folding tool, tolerance distribution is reasonably carried out, the gluing gapand the gluing pressure are controlled, and the product manufacturing precision and the gluing reliability are improved through rotation of the mold; finish machining is carried out before the product is taken off the rack, the assembly stress is eliminated and the parts are enabled to meet the interchangeability requirement.

Owner:XIAN AISHENG TECH GRP +1

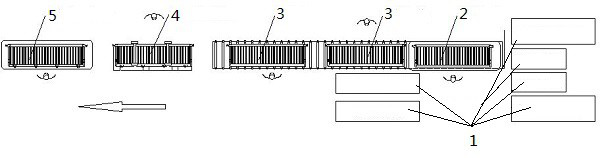

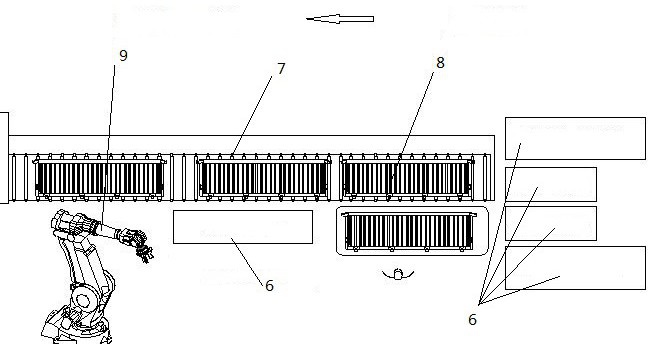

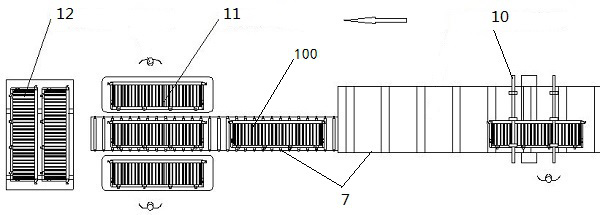

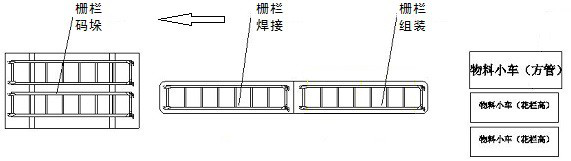

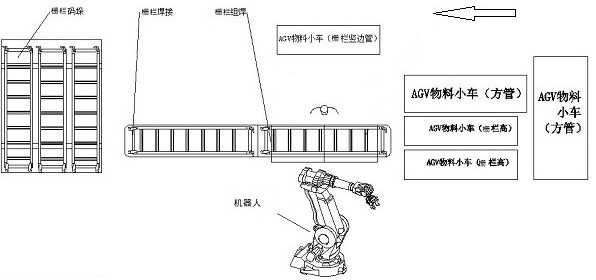

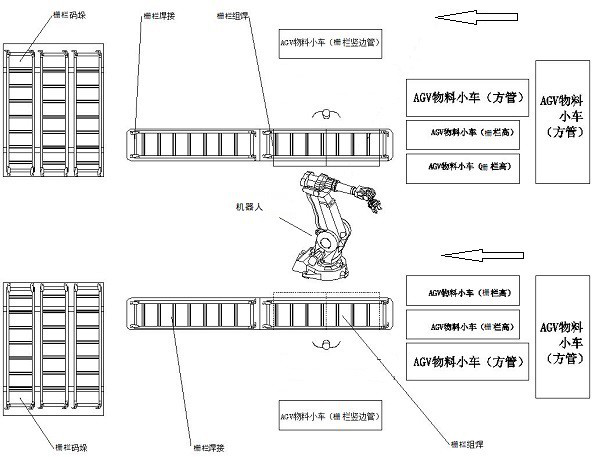

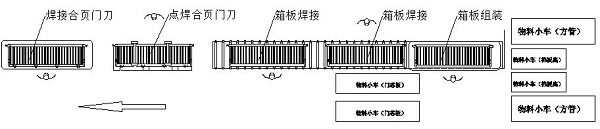

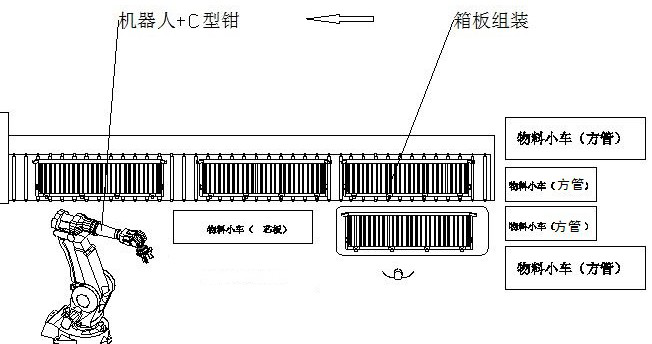

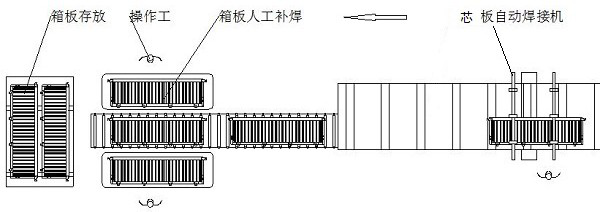

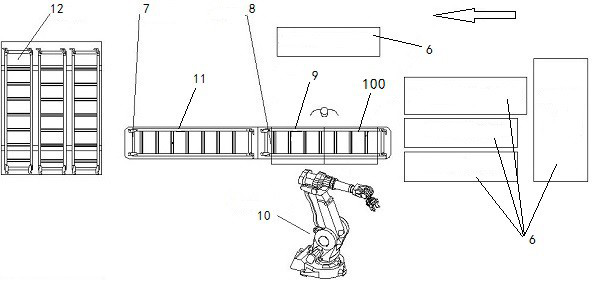

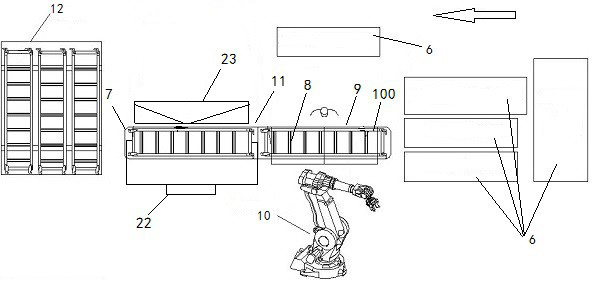

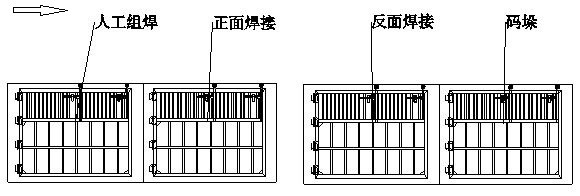

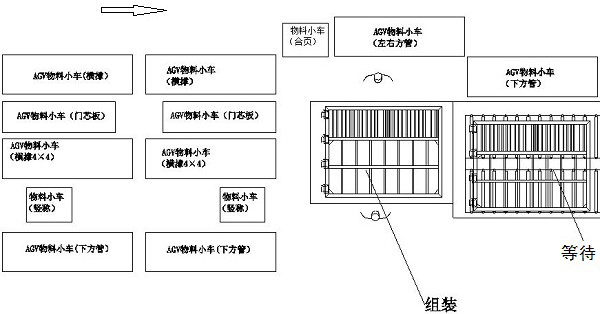

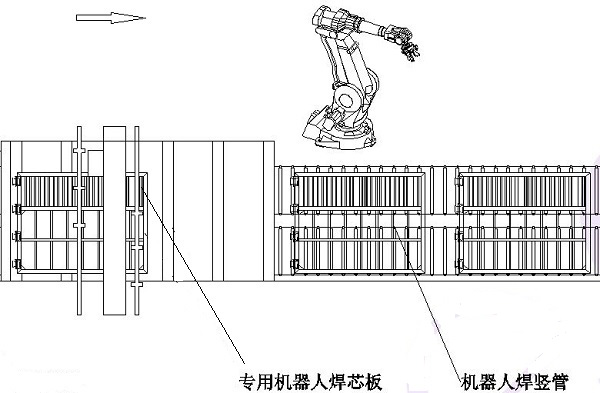

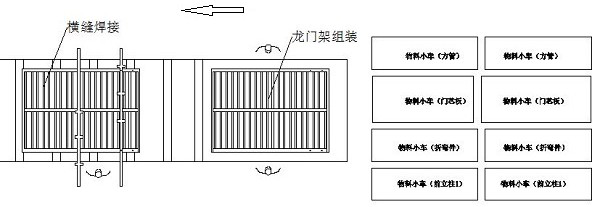

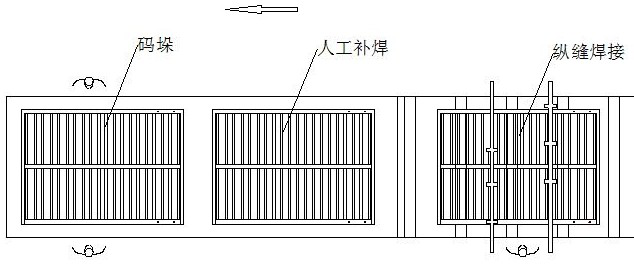

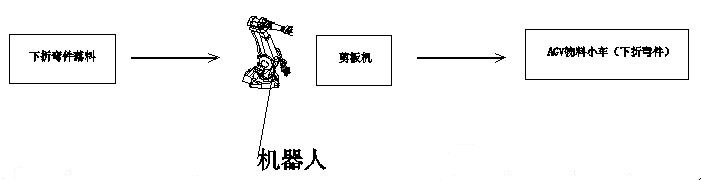

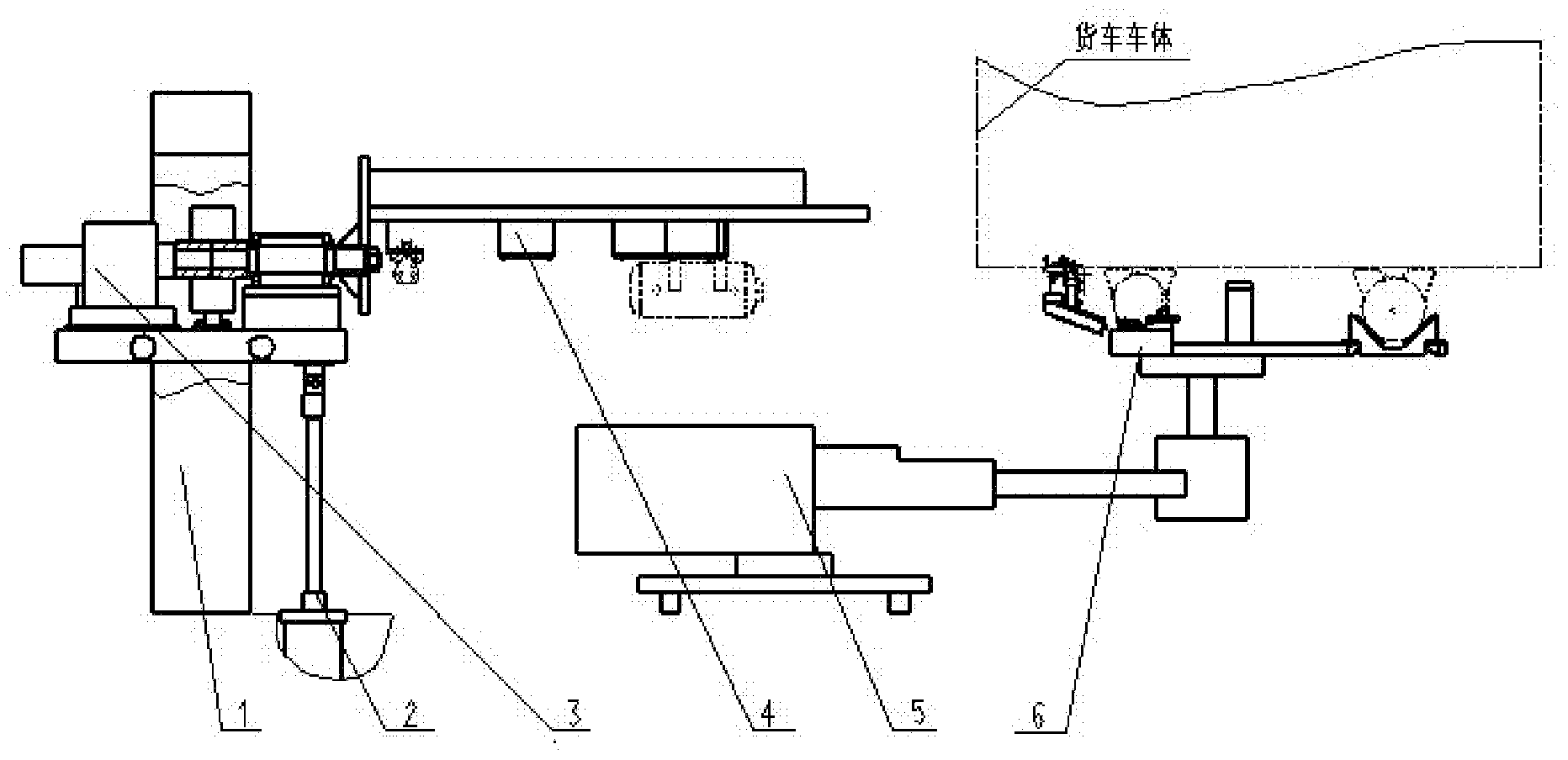

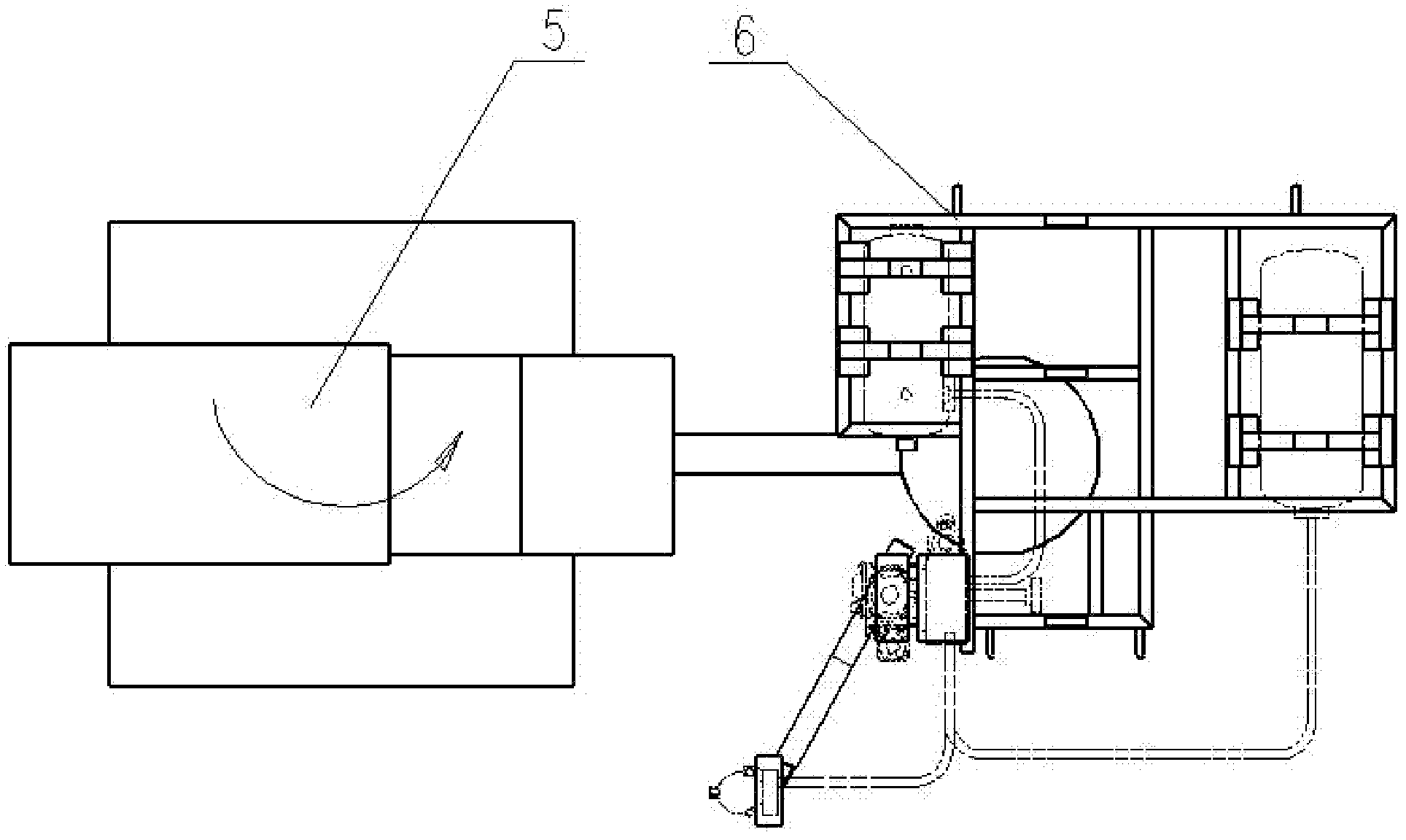

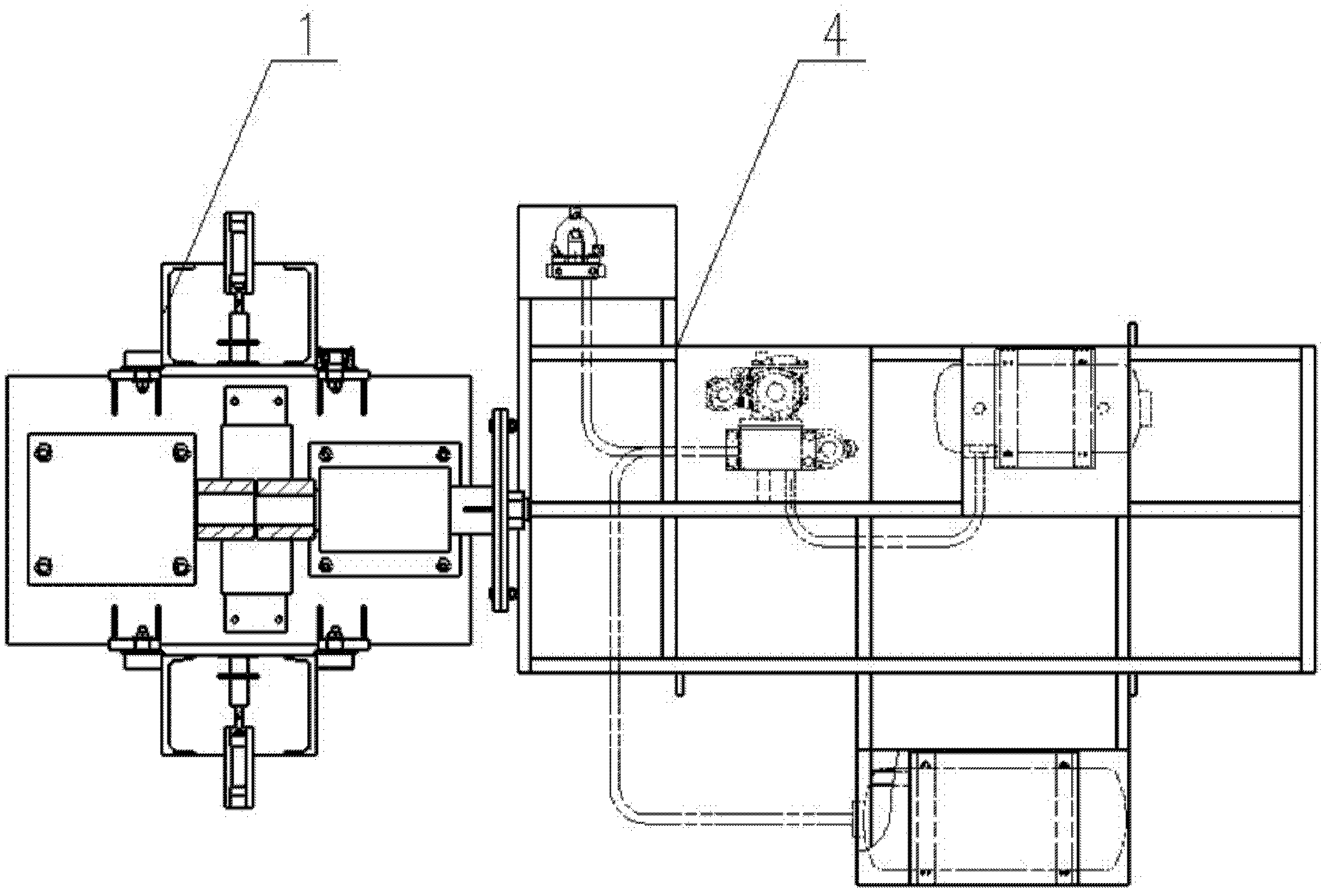

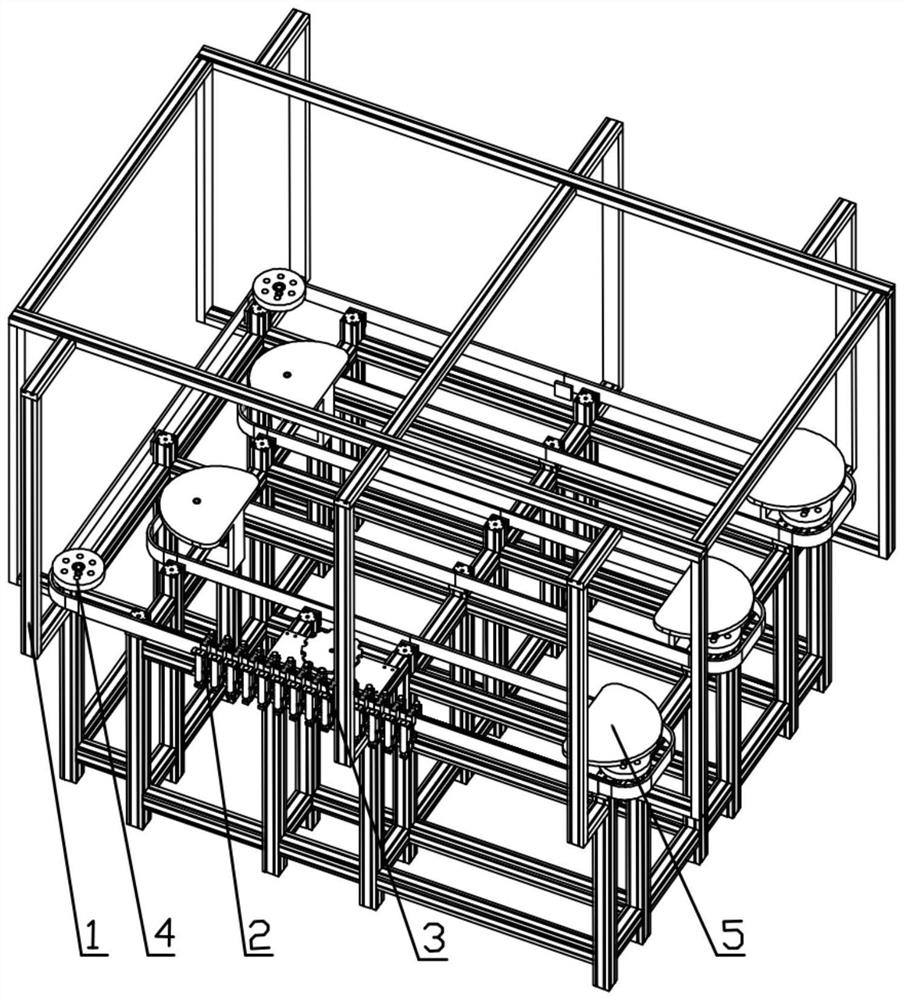

Semi-trailer carriage plate production line

PendingCN114248031AHigh precisionReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesMachineSemi-trailer

The semi-trailer carriage plate production line comprises conveying equipment, an assembling tool arranged on the conveying equipment, spot welding equipment located beside the conveying equipment, a special welding machine located beside the conveying equipment and located at the rear end of the spot welding equipment, and an independently-arranged control system. Assembling parts including the core plate, the vertical edge pieces, the transverse edge pieces and the like by adopting an assembling tool; spot welding equipment is adopted for spot welding positioning; welding the core plate by adopting a special welding machine; and the control system is adopted to control the position and the beat of each station node on the transmission equipment, and the workpieces flow on the transmission equipment, so that the production line operation is completed. According to the robot-operated intelligent automatic production line capable of achieving automatic pressure welding, automatic welding and compartment plate interchanging standardized production, production is organized in a standardized mode, produced workpieces completely meet the interchangeability requirement, the production efficiency is improved by 100%, manpower is saved by 70%, the cost is reduced, and the working environment is improved.

Owner:山东华耀汽车配件有限公司

Forming die for composite dual-insertion lug piece of solar energy unmanned aerial vehicle engine compartment

InactiveCN111113948AGuaranteed sizeImprove accuracyDomestic articlesUncrewed vehicleStructural engineering

The invention discloses a forming die for a composite dual-insertion lug piece of a solar energy unmanned aerial vehicle engine compartment. The forming die comprises a connecting bottom plate, positioning pins and fastening bolts, wherein a supporting swage die is arranged on the connecting bottom plate, a first fixing seat and a second fixing seat are respectively arranged at the positions, at the two ends of the supporting swage die, of the connecting bottom plate, a left swage die is arranged on the left side above the first fixing seat and the second fixing seat, a right swage die is arranged on the right side above the first fixing seat and the second fixing seat, a compression die is arranged at the middle position above the first fixing seat and the second fixing seat, and the inner side molded surfaces of the left swage die, the right swage die and the compression die transmit pressure through silica gel pressure equalizing plates so as to compact a composite part. According to the forming die, the supporting swage die, the left swage die, the right swage die and the compression die form a combined matched-die mode, so that the assembly, the disassembly and the demolding are convenient and simple, the die assembly is positioned by virtue of the positioning pins, the fastening bolts are fastened, and it is ensured that the size and the precision of a composite materialworkpiece are stable.

Owner:AEROSPACE SHENZHOU AIRCRAFT

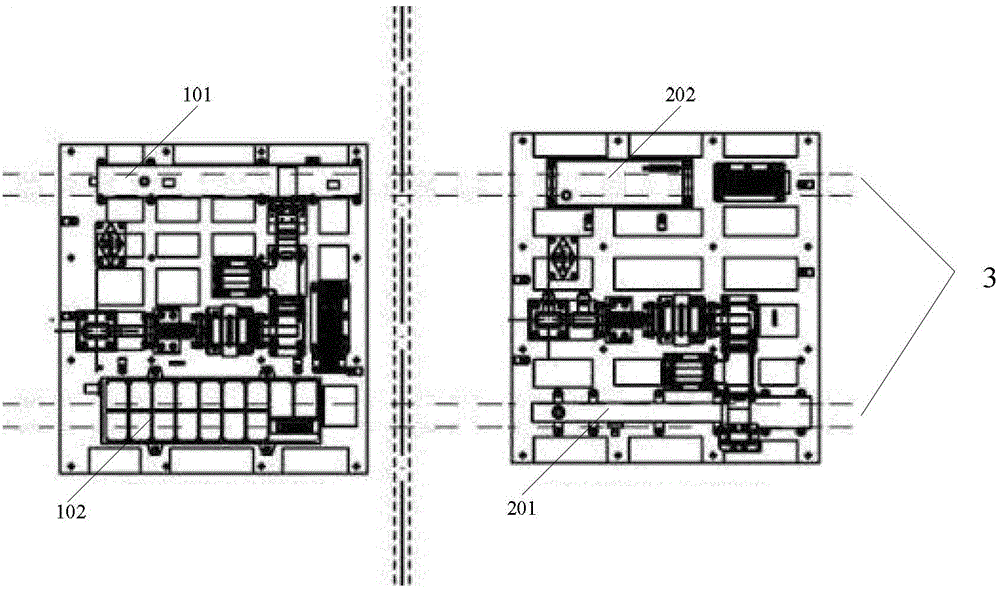

Interchangeability design method for domestic satellite-mounted travelling-wave tube amplifier and imported satellite-mounted travelling-wave tube amplifier

ActiveCN102751153AMeet the requirements of interchangeabilityReasonable design methodTravelling-wave tubesTransit-tube coupling devicesSatellite dataAudio power amplifier

The invention provides an interchangeability design method for a domestic satellite-mounted travelling-wave tube amplifier and an imported satellite-mounted travelling-wave tube amplifier. The method comprises a step of mechanical interface interchangeability design, a step of input excitation interchangeability design and a step of usage pattern interchangeability design, wherein the step of mechanical interface interchangeability design comprises enabling installing interfaces of two travelling-wave tubes to be consistent with each other, be consistent with heat pipe layout interfaces positioned on a satellite structure boards and be consistent with antenna waveguide output interfaces; the step of input excitation interchangeability design comprises adjusting intensity of input excitation signals by externally connecting a fixed attenuator so as to meet the requirements of excitation of different saturation points of the two travelling-wave tubes; and the step of usage pattern interchangeability design comprises adding movement options of instructions such as starting / shutdown, feeding low pressure and discharging low pressure in operations schedule design so as to meet the requirements of two products for different usage patterns. According to the interchangeability design method, interchanging usage of the domestic travelling-wave tube amplifiers and the imported travelling-wave tube amplifier can be achieved, and flexibility in product matching in a subsystem scheme is guaranteed. The interchangeability design method is already applied in some satellite data transmitting subsystem.

Owner:SHANGHAI SATELLITE ENG INST

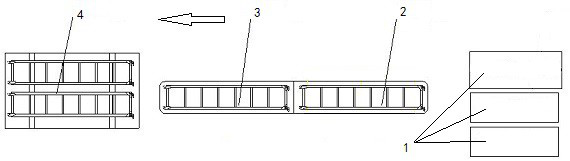

Semitrailer fence production line

InactiveCN112025057AHigh precisionReduce labor intensityWelding accessoriesControl systemVertical edge

The invention relates to a semitrailer fence production line. The semitrailer fence production line comprises conveying equipment, an assembling tool, a welding robot and a control system; the assembling tool is used for assembling parts such as fence height parts, vertical edge parts and transverse edge parts. spot welding positioning is conducted through the welding robot; the welding robot is used for welding the fence height parts; and the control system is adopted to control the position and beat of each station node on the conveying equipment, so that the production line work is completed. Thus, the robot-operated intelligent automatic production line capable of achieving automatic spot welding, automatic welding and fence interchange standardized production belongs to intelligent manufacturing of traditional industry transformation and updating, and has the advantages that production automation and standardized organization and production are achieved, produced workpieces completely meet the interchange requirement, the workpiece precision is high, automatic production is achieved, the labor intensity of staff is reduced, the production efficiency is improved by 100%, manpower is saved by 70%, the cost is reduced, and the operation environment is improved.

Owner:山东华耀汽车配件有限公司

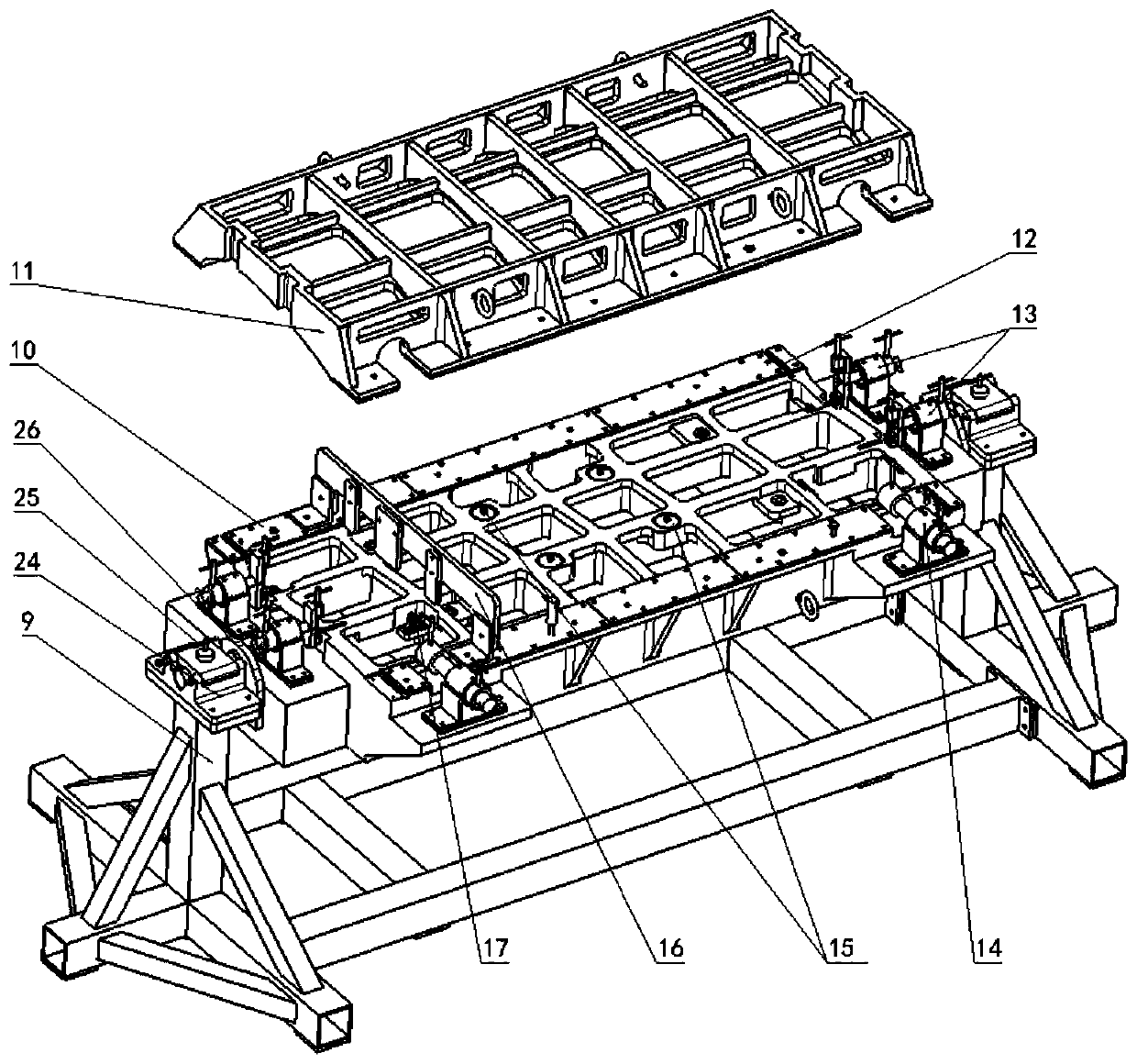

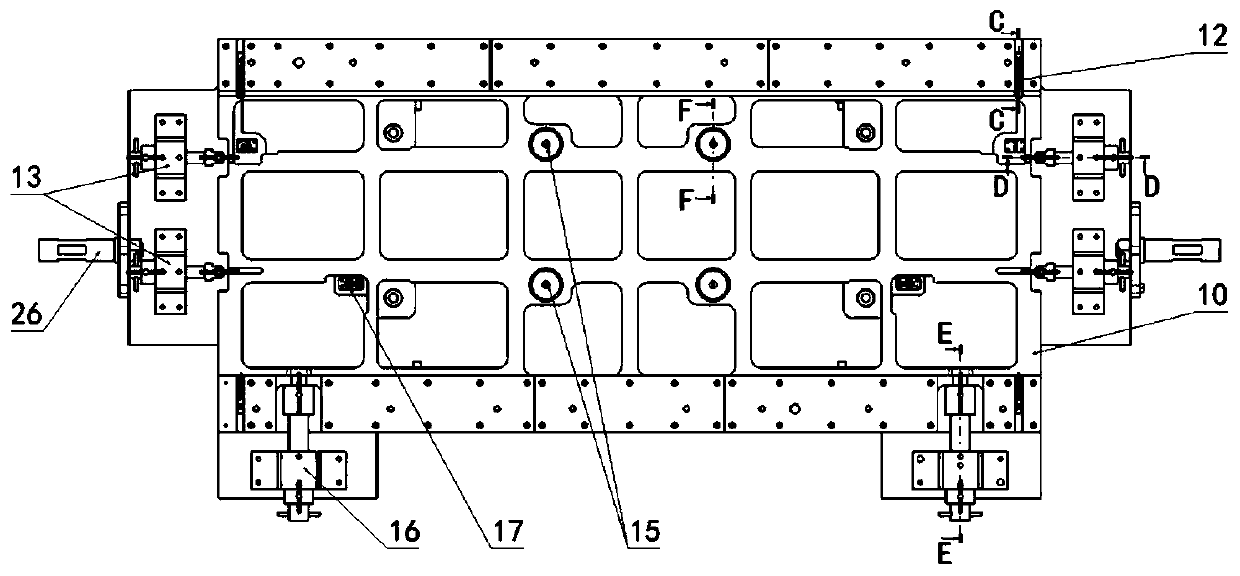

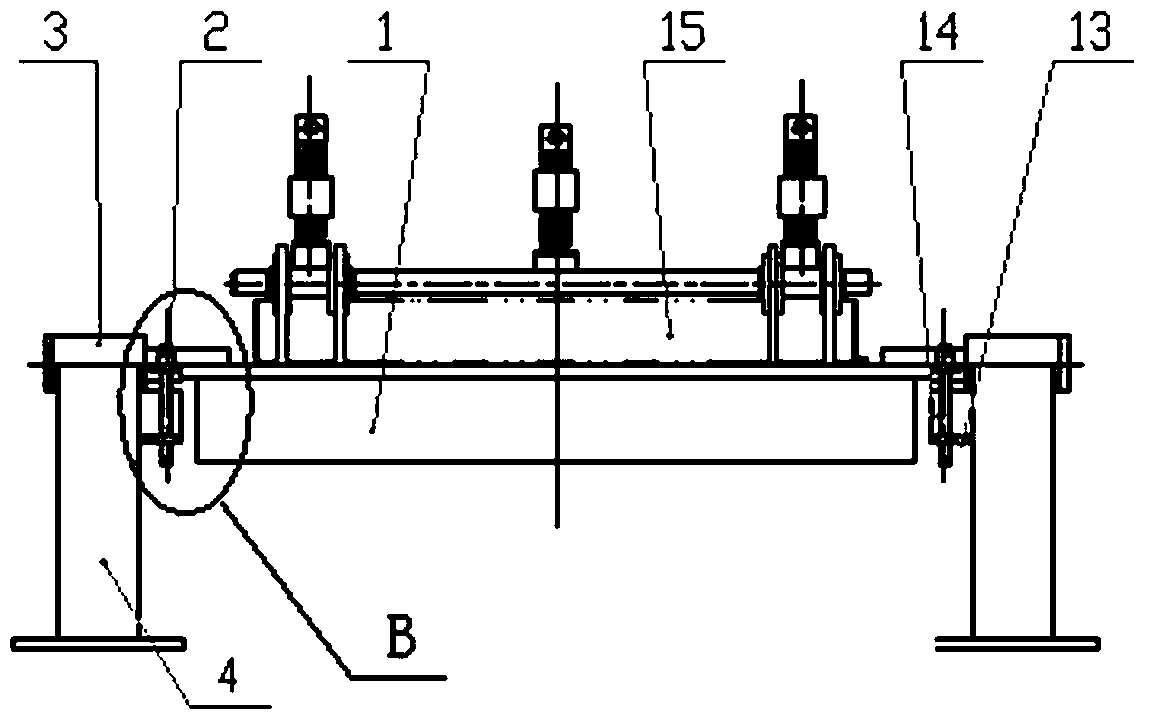

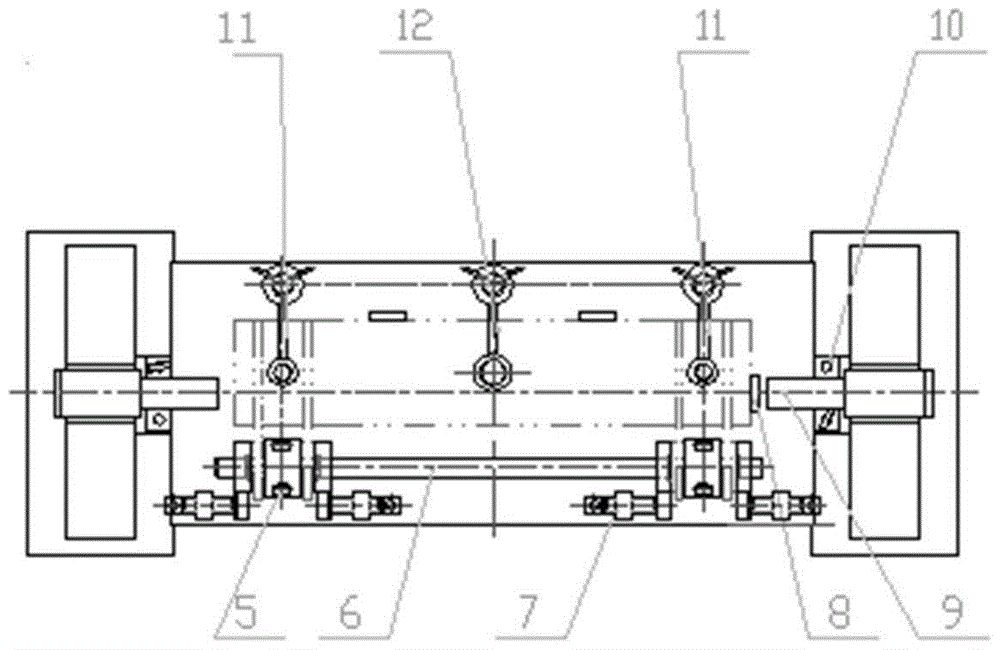

Assembly welding device

ActiveCN103394859AHigh dimensional accuracyEasy to shapeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to an assembly welding device which comprises a workbench, supports for bracing the workbench, locating components which are fixed on the workbench and used for locating, and compaction components used for compacting, wherein rotating shafts and reinforced plates are arranged on the two sides of the workbench; shaft sleeves are arranged at the upper parts of the supports; bracing transverse plates are arranged on the side surfaces of the supports; bracing vertical plates are arranged between the bracing transverse plates and the shaft sleeves, and perpendicular to the bracing transverse plates; the rotating shafts are mounted in the shaft sleeves; first holes are formed in the reinforced plates; second holes are formed in the bracing transverse plates; third holes are formed in the bracing vertical plates; the workbench rotates with rotating of the rotating shafts; and locating pins are inserted into the first holes and the second holes, or inserted into the first holes and the third holes, so that the workbench is fixed. The assembly welding device can control welding deformation effectively, so that the assembly size accuracy and the shape position accuracy of a subframe front transverse beam welding piece are ensured; the product quality is improved; and an exchange requirement of the consistency of a product is met.

Owner:BEIJING SANXING AUTOMOBILE

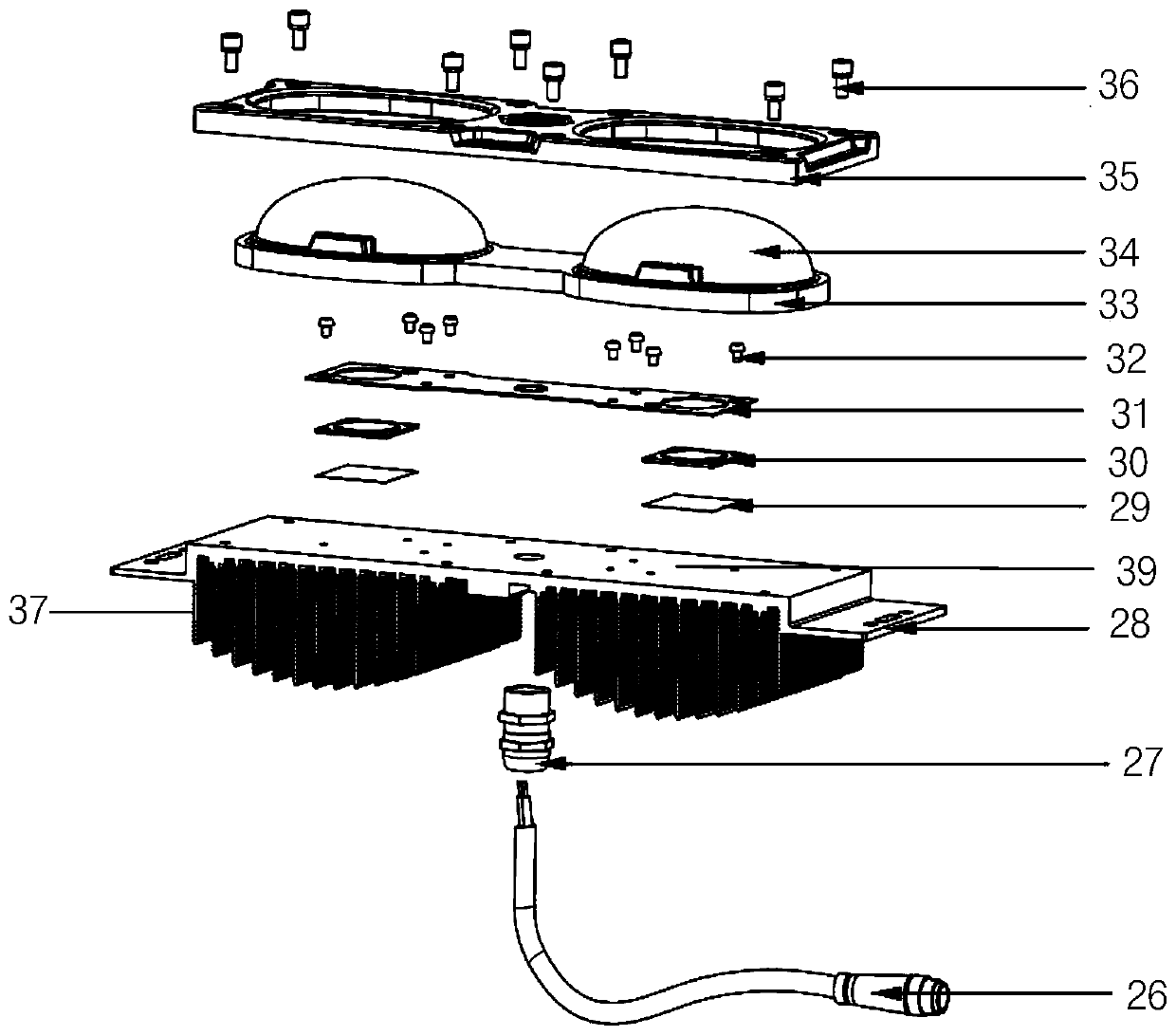

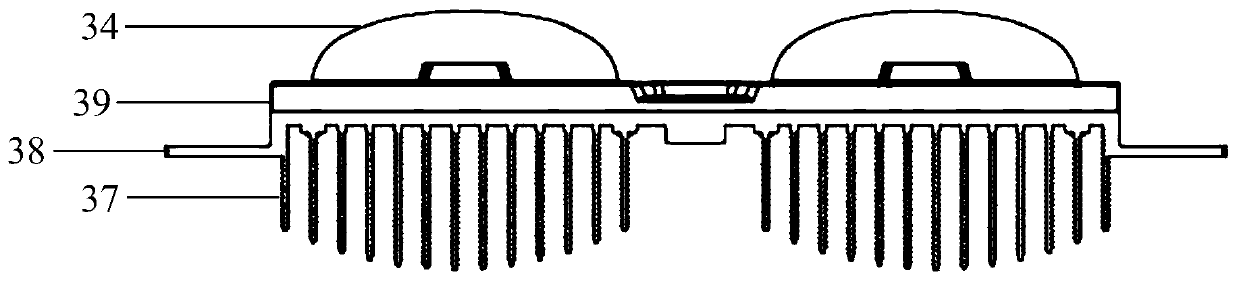

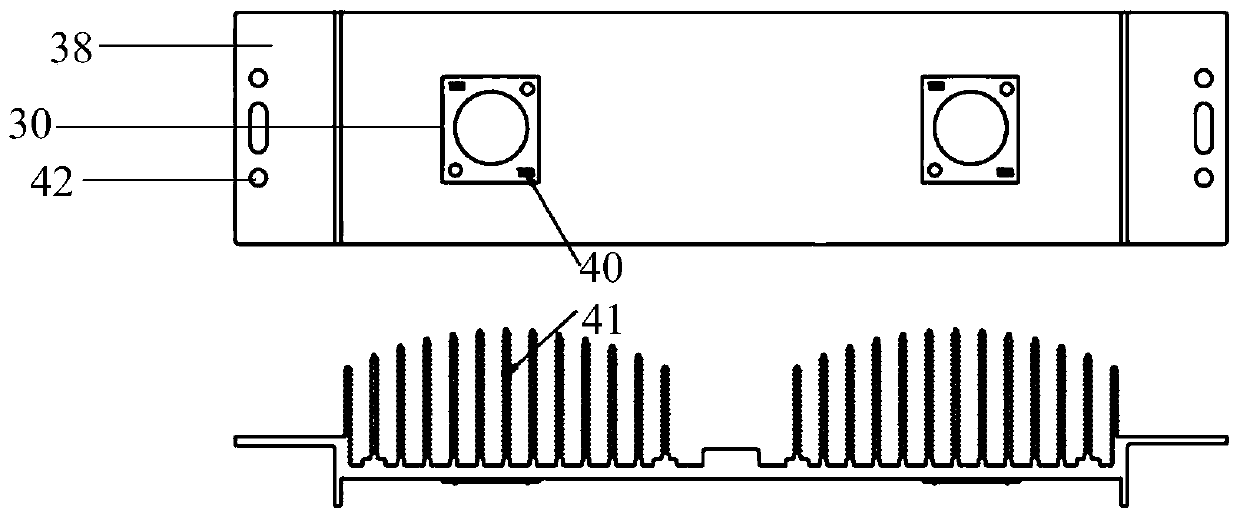

LED light source module and intelligent lamp cap

InactiveCN110319384AExtended service lifeImprove cooling effectElectric circuit arrangementsLighting heating/cooling arrangementsEngineeringHeat spreader

The invention discloses an LED light source module. The LED light source module comprises a radiator, one or more light source chips, glass lenses with the number being equal to that of the light source chips, a PCB connecting board and a pressing cover, wherein the radiator comprises a heat dissipation base plate and at least one group of heat dissipation fins; the heat dissipation fins are positioned on the same side of the heat dissipation base plate and are vertical to the heat dissipation base plate; each group of heat dissipation fins comprises three or more heat dissipation fins; in each group of heat dissipation fins, the heat dissipation fins are arranged in parallel; in each group of heat dissipation fins, in the direction vertical to the heat dissipation base plate, the lengthsof the different heat dissipation fins are gradually reduced towards two ends from the middle; and the light source chips are connected with the radiator, the PCB connecting board is connected with the light source chips and the radiator, and the glass lenses are fixed on the PCB connecting board. The invention further discloses an intelligent lamp cap comprising the LED light source module. The LED light source module provided by the invention is uniform in heat dissipation, good in heat dissipation effect, little in used material, small in integral weight and size, low in cost, and convenient to replace.

Owner:HUZHOU MINGSHUO OPTOELECTRONICS TECH CO LTD +1

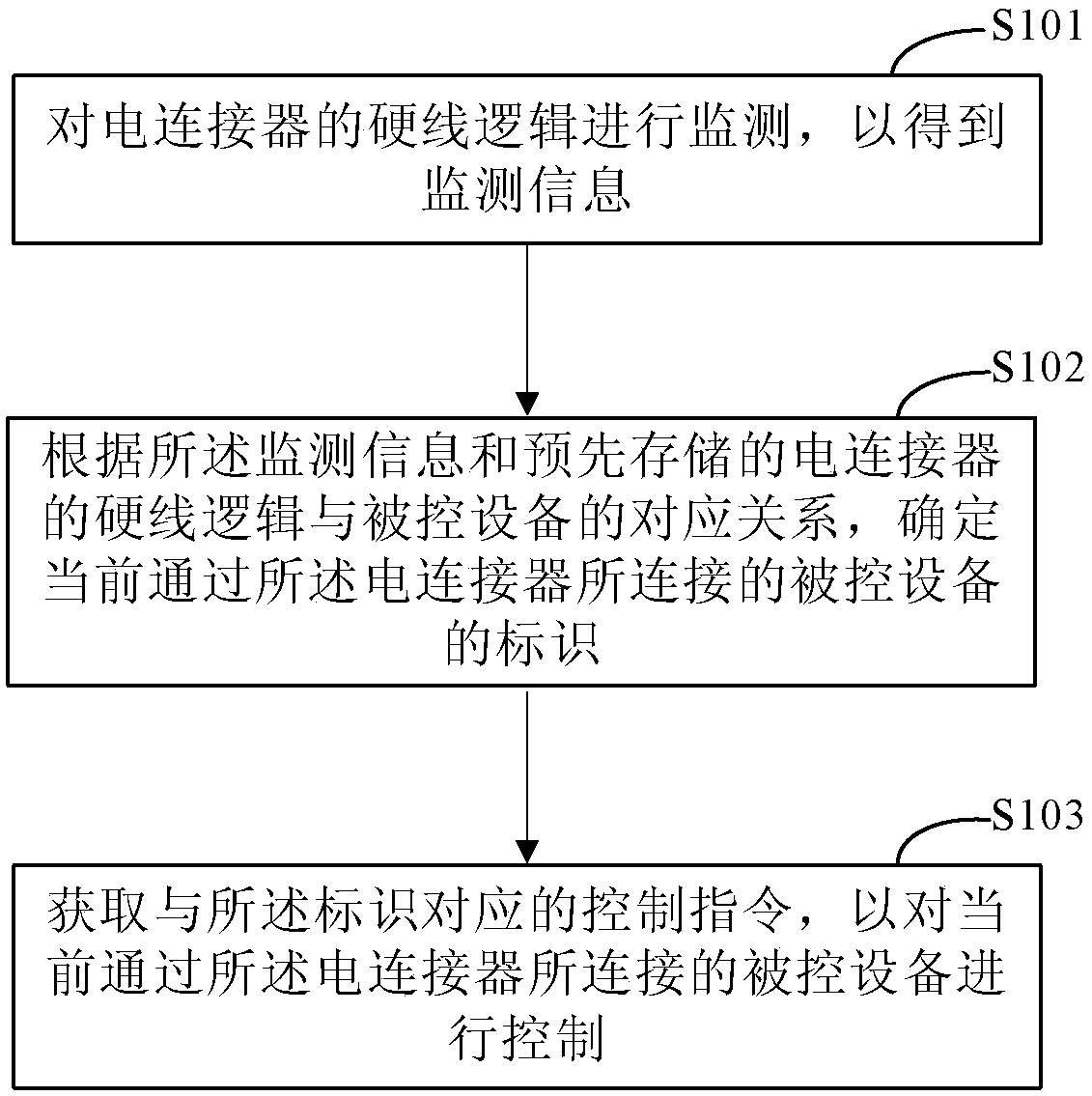

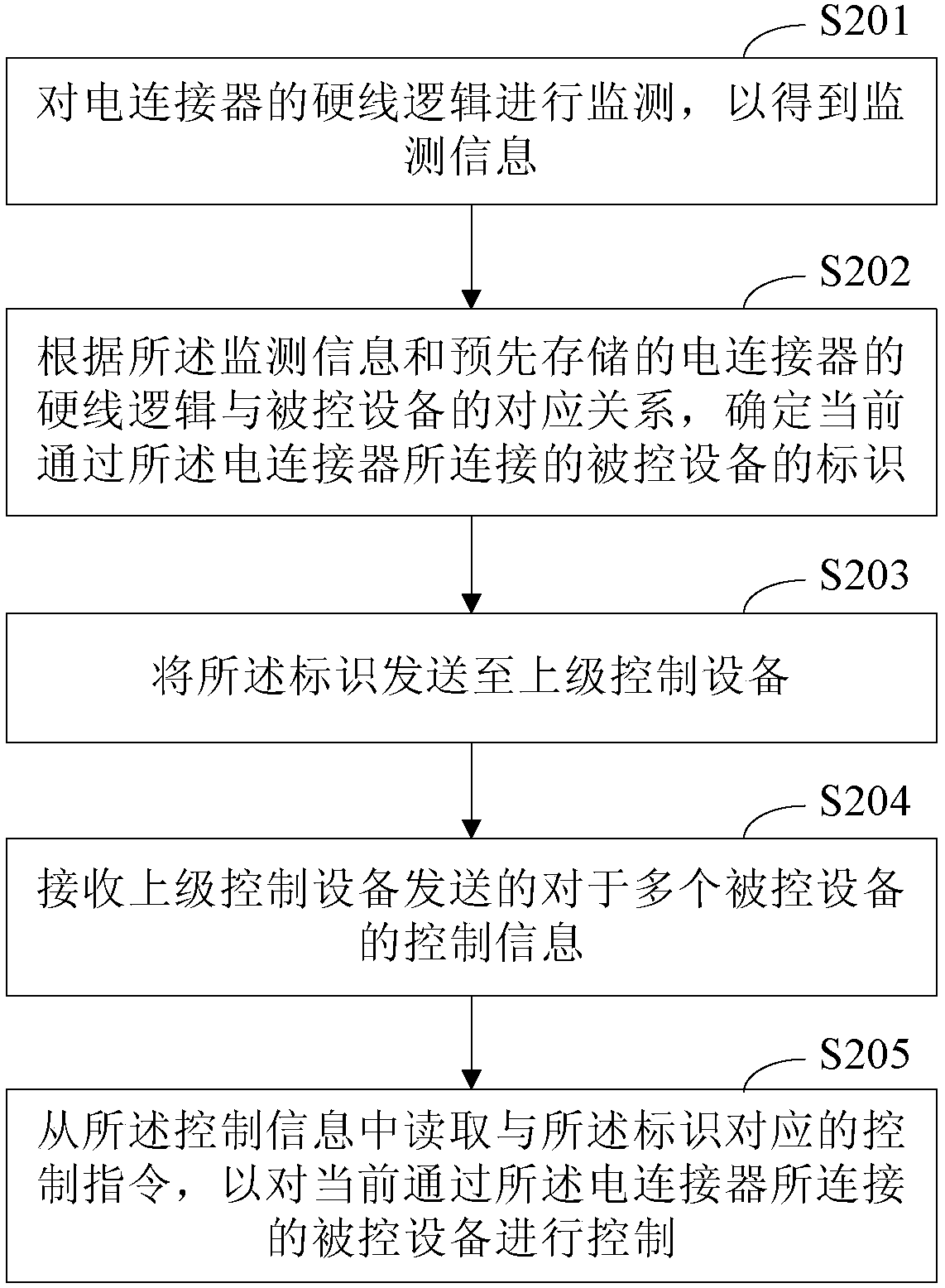

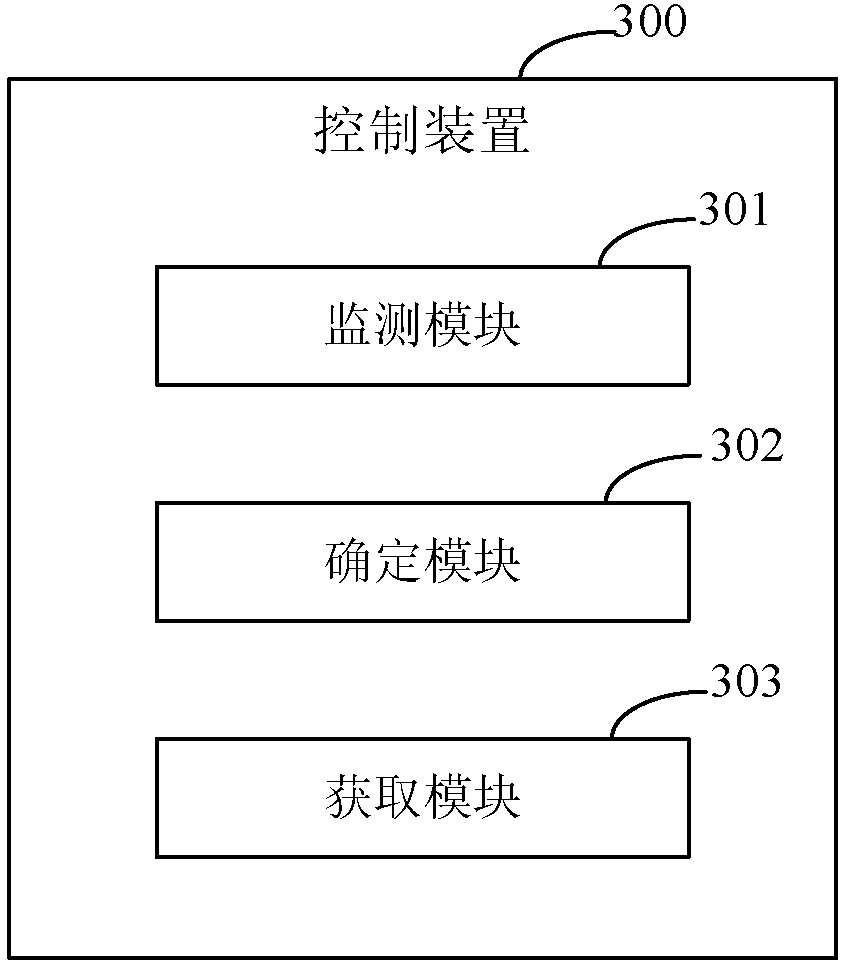

Control method and device

InactiveCN110196581AMeet the requirements of interchangeabilityProgramme controlElectric testing/monitoringElectricityElectrical connector

The invention, which relates to the technical field of computers, discloses a control method and device. The method includes: monitoring a hard-wired logic of an electrical connector to obtain monitoring information; determining an identifier of a controlled device connected to the electrical connector based on the monitoring information and a pre-stored correspondence relationship between the hard-wired logic of the electrical connector and the controlled device; and acquiring a control instruction corresponding to the identifier and thus controlling the controlled device currently connectedthrough the electrical connector. Therefore, the currently connected controlled device can be correctly identified and controlled after a manual operation error is caused, so that the connected controlled device can complete the correct action.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

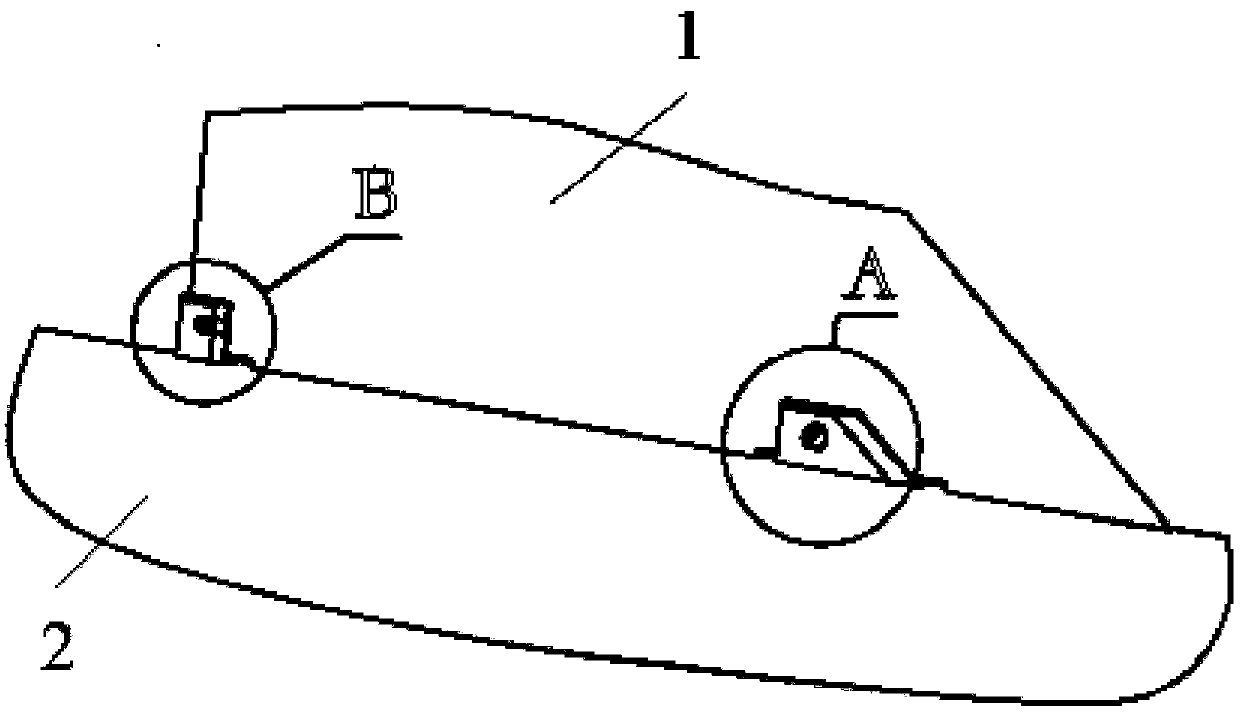

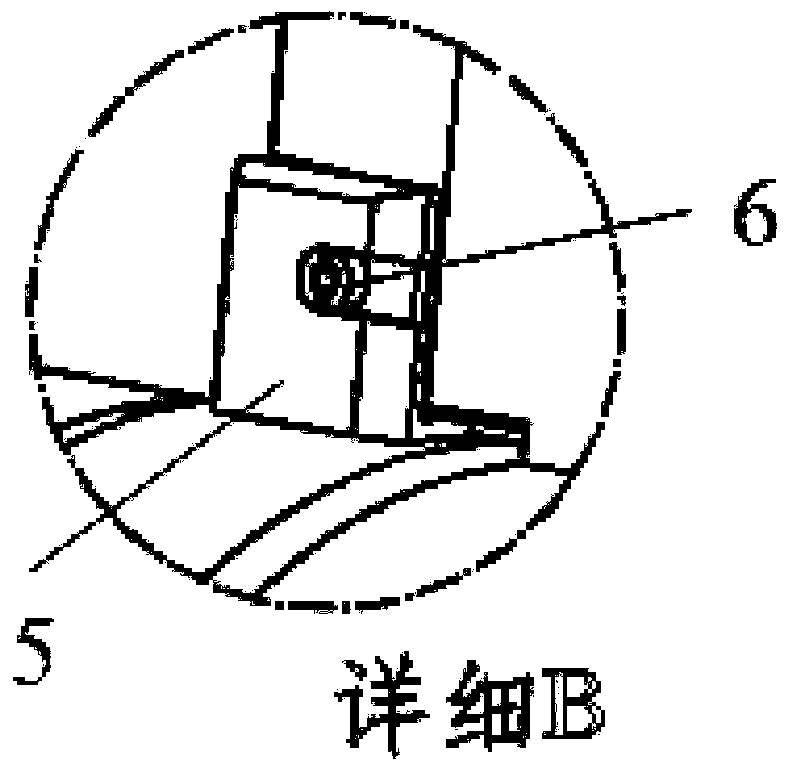

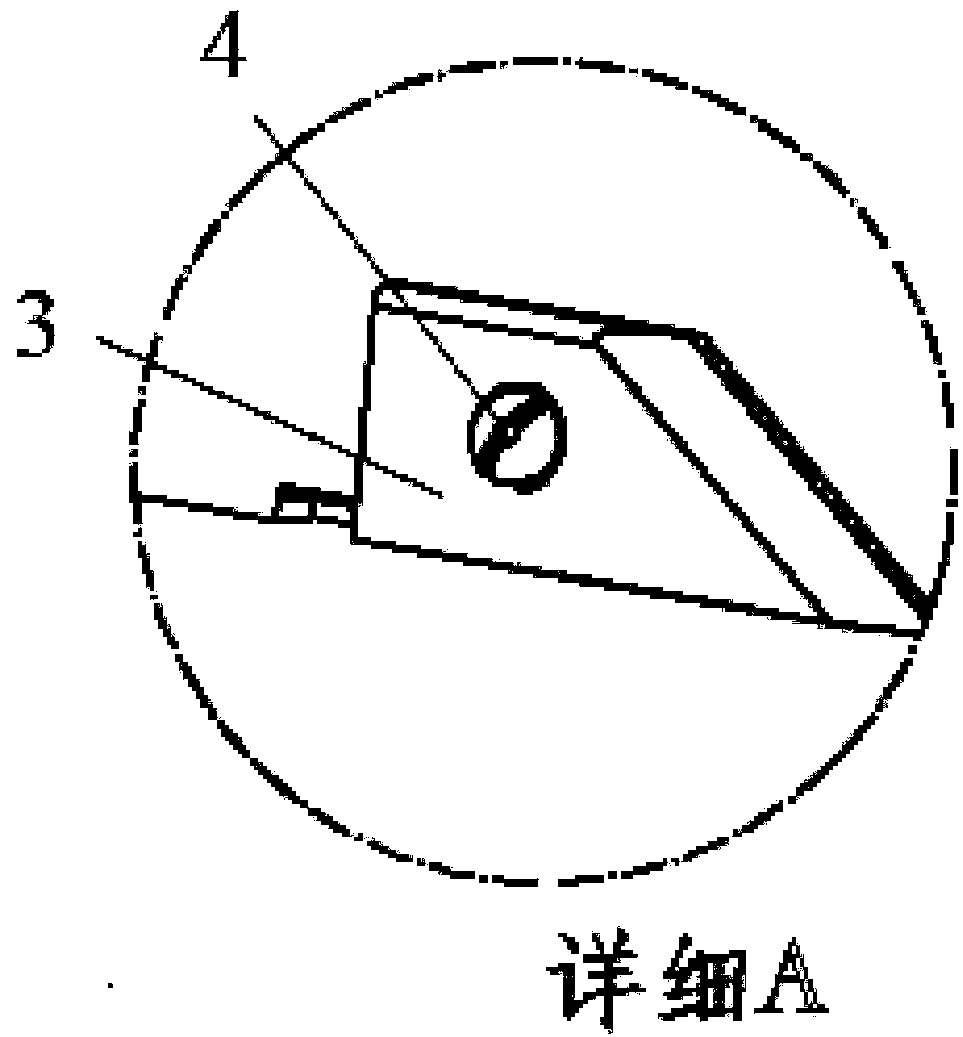

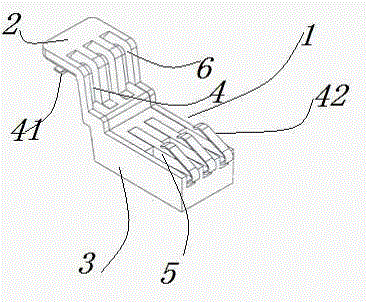

Missile wing quick disassembling structure

The invention relates to a missile wing quick disassembling structure, which comprises self-made bolt nuts (6), a main lug sheet (3), an auxiliary lug sheet (5) and a locking screw (4). The main lug sheet (3) and the auxiliary lug sheet (5) are arranged on a missile bay (2), and a U-shaped positioning groove is formed in the front end of the auxiliary lug sheet (5); a missile wing (1) is providedwith a main lug sheet matching face (9) and an auxiliary lug sheet matching face (7); and the auxiliary lug sheet matching face (7) is provided with a positioning hole (8), the self-made screw nuts (6) can be inserted into the U-shaped positioning groove, and the main lug sheet (3) is provided with a threaded hole for being matched with the locking screw (4). According to the missile wing quick disassembling structure, the missile wing quick disassembling function is achieved, the missile wing is reliably connected through the locking screw, the time of assembling and disassembling of the missile wing is greatly reduced, the structure is simple, and the missile wing meets the interchangeability requirement.

Owner:JIANGXI HONGDU AVIATION IND GRP

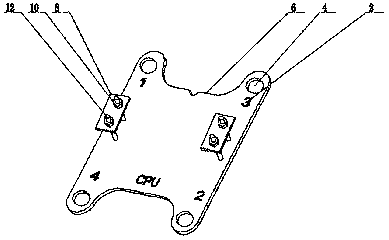

Radiator assembly

InactiveCN103425214ADoes not affect connection strengthEasy to disassembleDigital data processing detailsEngineeringUltimate tensile strength

The invention discloses a radiator assembly which comprises an aluminum sheet with a PCB fixedly installed on the surface, wherein a plurality of first through holes are further formed in the aluminum sheet. The radiator assembly is characterized in that the radiator assembly further comprises a cooling fin, an accommodating space capable of accommodating the aluminum sheet in a clamped mode is formed in the cooling fin, second through holes are further formed in the cooling fin, and the first through holes and the second through holes are concentric when the aluminum sheet is clamped into the cooling fin. According to the radiator assembly, due to the fact that the aluminum sheet on which the PCB is fixed is clamped into the accommodating space of the cooling fin in a buckling mode, dismantling can be achieved conveniently, interchangeability can be achieved, and connecting strength can not be affected after the radiator assembly is heated.

Owner:KUNSHAN WEIJIN HARDWARE PROD

Semitrailer boxboard production line

InactiveCN112025129AHigh precisionReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesProduction lineRobot hand

The invention relates to a semitrailer boxboard production line. The semitrailer boxboard production line comprises conveying equipment, an assembling tool, a mechanical arm, an automatic welding machine and a control system, wherein the assembling tool is used for assembling parts such as core veneers, vertical edge pieces and transverse edge pieces, etc.; the mechanical arm is adopted for spot welding positioning; the automatic welding machine is adopted for welding the core veneers; and the control system is adopted to control the position and beat of each station node on the conveying equipment, so that the production line work is completed. The robot-operated intelligent automatic production line capable of achieving automatic pressure welding, automatic welding and standardized production of boxboard interchange belongs to intelligent manufacturing of traditional industry transformation and updating, and has the advantages that production automation and standardized organizationproduction are achieved, produced workpieces completely meet the interchange requirement, and the workpiece precision is high; the labor intensity of staff is reduced, the production efficiency is improved by 100%, and the manpower is saved by 70%; and the cost is reduced, and the working environment is improved.

Owner:山东华耀汽车配件有限公司

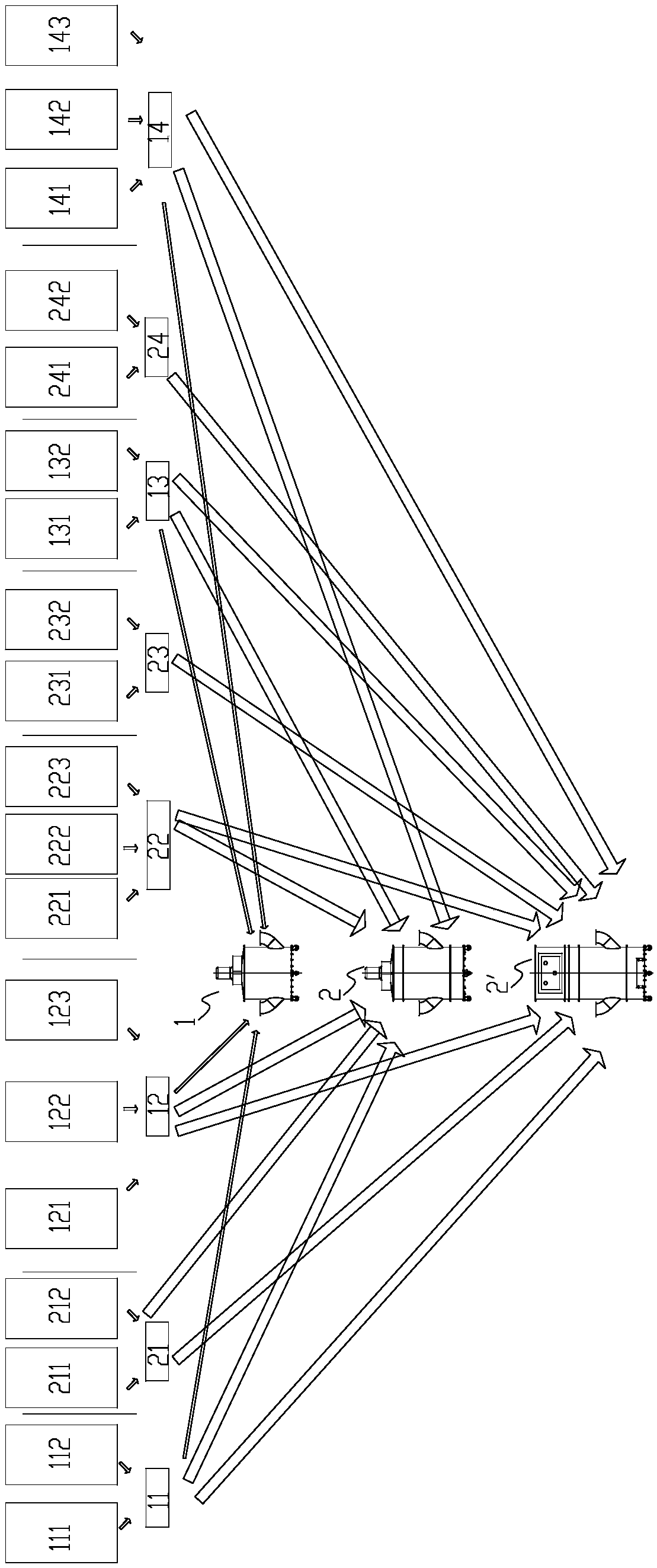

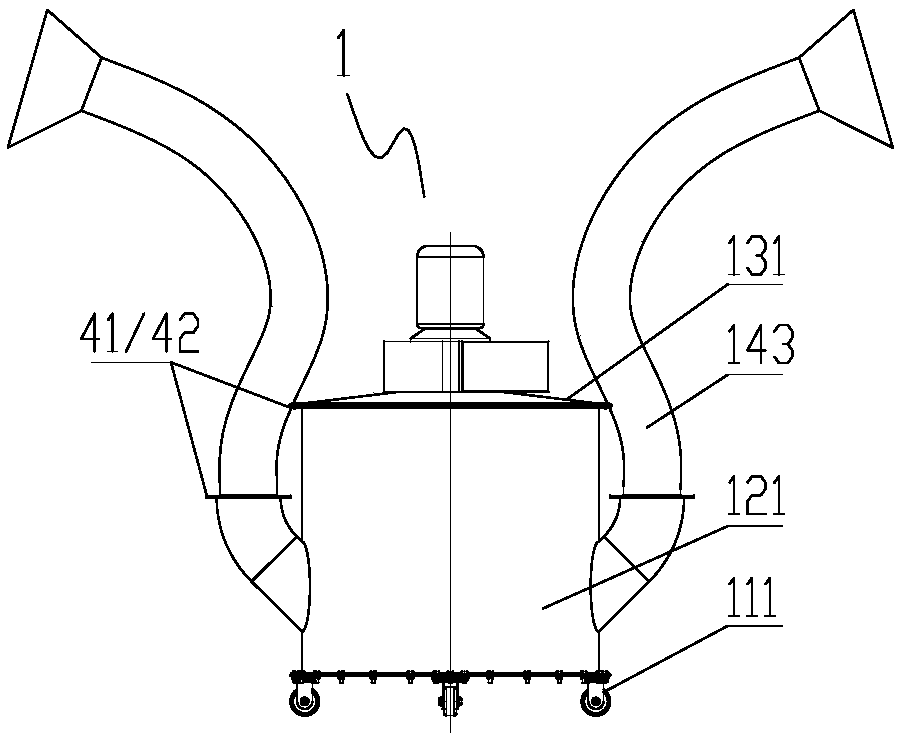

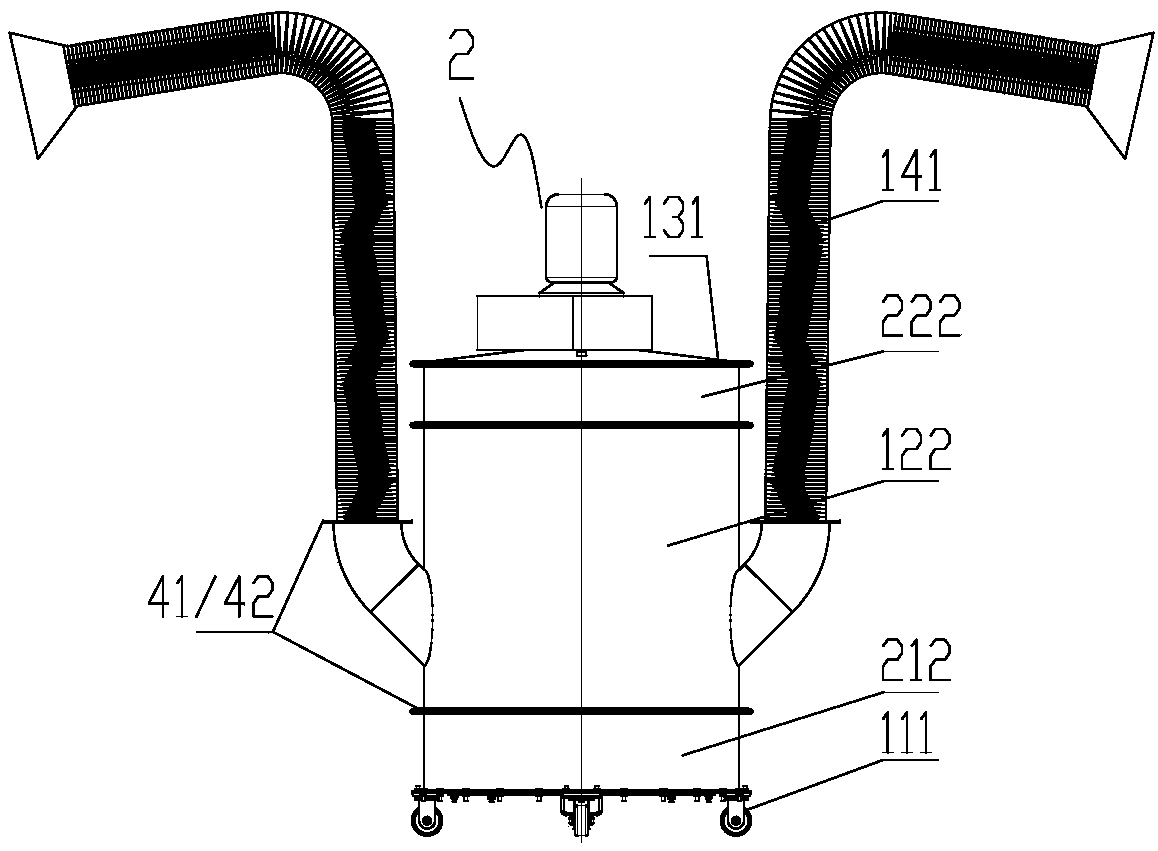

Module-assembly welding fume dust remover

PendingCN109364689AImprove consistencyStrengthen interchangeable developmentDispersed particle filtrationTransportation and packagingButt jointEngineering

The invention discloses a module-assembly welding fume dust remover. The module-assembly welding fume dust remover comprises a basic dust remover and optional modules, wherein the optional modules include a dust collection module, a back flushing module, an odor removal module and a sound deadening module, and detachable butt joint structures which are in butt joint with the basic dust remover arearranged on the optional modules respectively. Consistent butt joint interfaces are arranged among the basic dust remover and the other functional modules, any two functional modules can be mutuallyconnected into one, and according to the actual requirements, through the functional modules, welding fume dust removers with different functions can be formed, so that not only are standardization, modularization and serialization of welding fume dust remover equipment achieved, but also the personalized requirements are met emphatically.

Owner:长沙爱达环保科技有限公司

Welding device

ActiveCN103394859BHigh dimensional accuracyEasy to shapeWelding/cutting auxillary devicesAuxillary welding devicesVehicle framePulp and paper industry

A welding assembly device, including a workbench, a support for supporting the workbench, a positioning assembly fixed on the workbench for positioning and a pressing assembly for pressing, with rotating shafts and The reinforcement plate is provided with a shaft sleeve on the upper part of the support, a support horizontal plate is provided on the side of the support, a support vertical plate is provided between the support horizontal plate and the shaft sleeve, the support vertical plate is perpendicular to the support horizontal plate, and the shaft is installed In the sleeve, the first hole is processed on the reinforcement plate, the second hole is processed on the support horizontal plate, and the third hole is processed on the support vertical plate. The worktable rotates with the rotation of the shaft, and the positioning pin is inserted into the first hole and the second hole. Insert the middle or positioning pins into the first hole and the third hole to fix the workbench. The welding assembly device of the present invention can effectively control welding deformation, ensure the assembly size accuracy and shape position accuracy of the subframe front beam welded parts, improve product quality, and meet the interchange requirements of product consistency.

Owner:BEIJING SANXING AUTOMOBILE

Semitrailer fence production line

PendingCN114248032AHigh workpiece precisionReduce manual labor intensityWelding/cutting auxillary devicesAuxillary welding devicesTransmission equipmentWorking environment

The invention relates to a semitrailer fence production line. The semitrailer fence production line comprises conveying equipment, an assembling tool, a welding robot and a control system; the assembling tool is used for assembling parts such as fence height parts, vertical edge parts and transverse edge parts; the welding robot is adopted for spot welding positioning; the welding robot is adopted to weld the fence height; and the control system is adopted to control the position and the beat of each station node on the transmission equipment, so that the production line operation is completed. Thus, the robot-operated intelligent automatic production line capable of achieving automatic spot welding, automatic welding and fence interchanging and standardized production belongs to intelligent manufacturing of transformation and updating of traditional industries, and has the advantages that production automation and standardized organization production are achieved, produced workpieces completely meet the interchanging requirement, the precision of the workpieces is high, and the production efficiency is high. Automatic production is achieved, the labor intensity of workers is reduced, the production efficiency is improved by 100%, manpower is saved by 70%, cost is reduced, and the working environment is improved.

Owner:山东华耀汽车配件有限公司

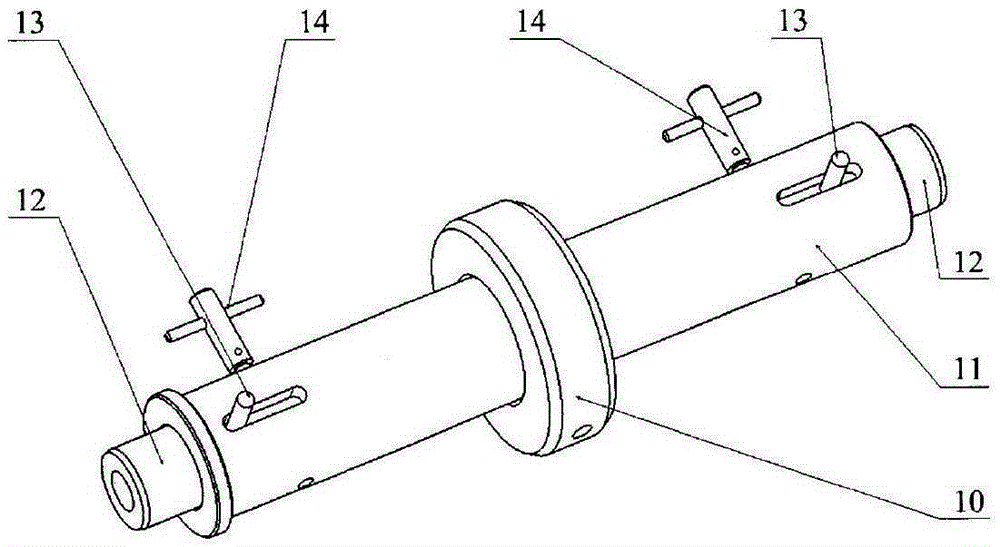

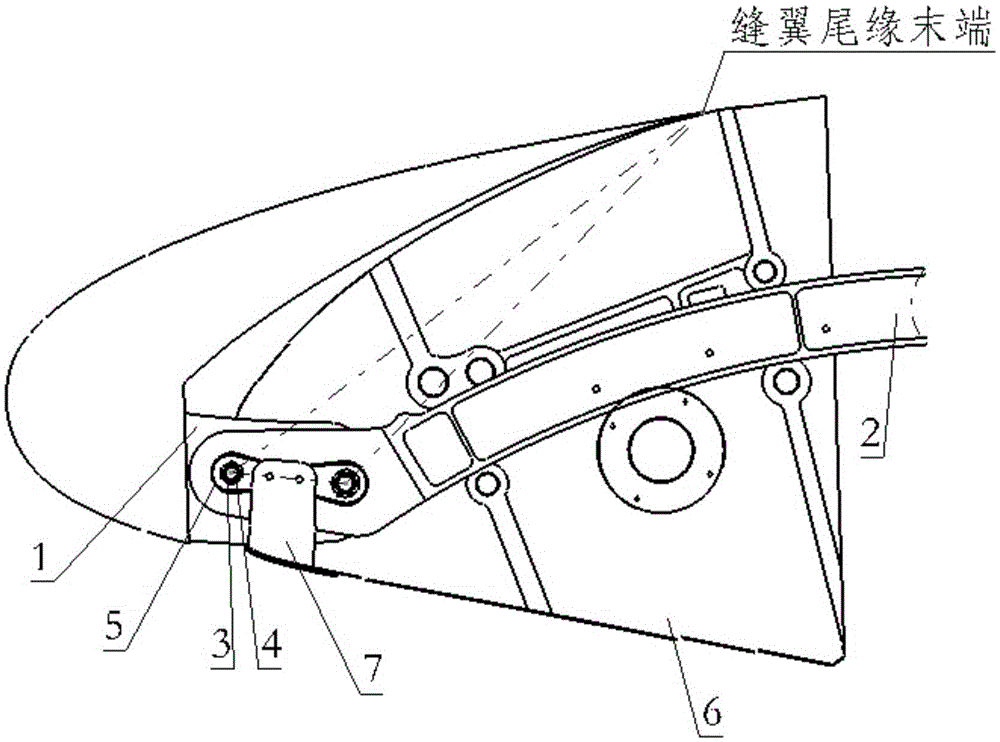

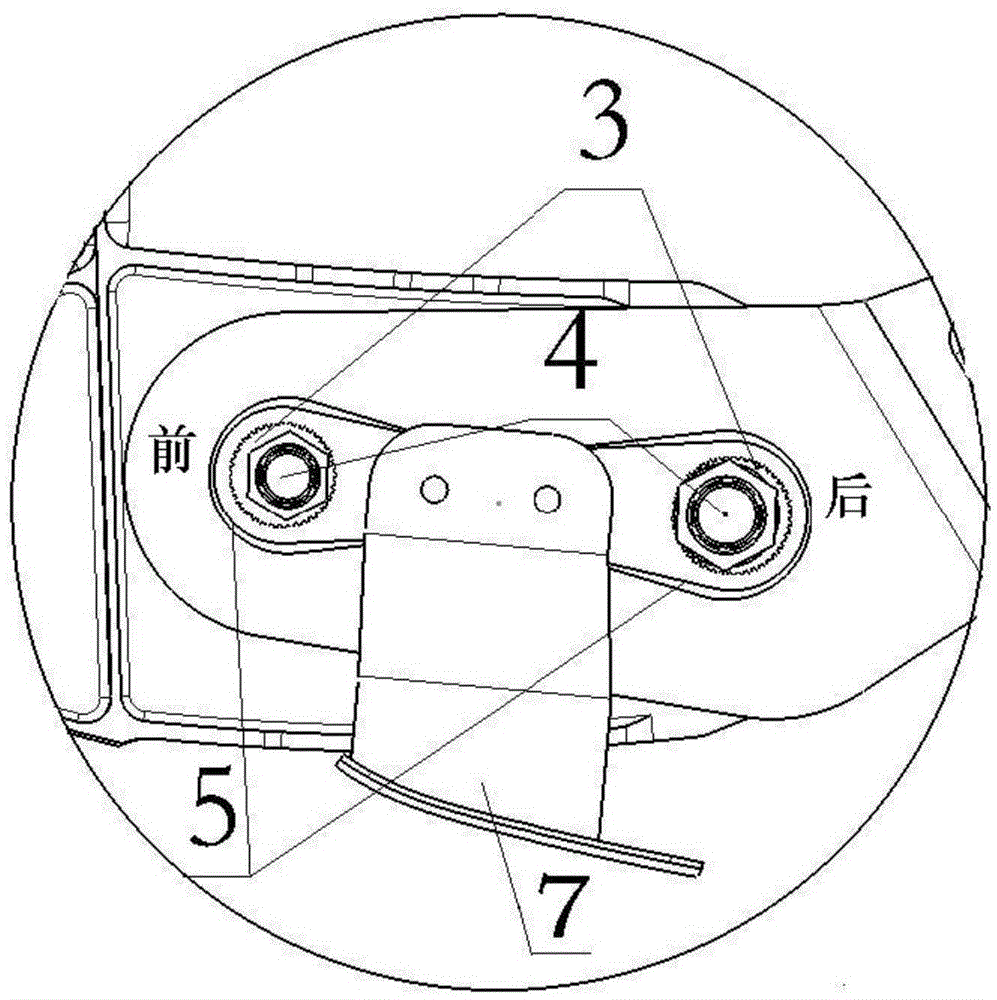

A leading edge slat with adjustable attitude

The invention belongs to the design technology of aircraft movable surfaces, in particular to a leading edge slat with adjustable attitude. The attitude-adjustable leading edge slat includes a reinforcing rib (1), a slide rail (2), and a double eccentric bushing (3), wherein the reinforcing rib (1) passes through two holes connecting the lug and the slide rail (2). For fixed connection, two sets of double eccentric bushings (3) are respectively arranged in the outer connecting holes between the reinforcing rib (1) and the slide rail (2), and fixed by stud bolts (4). The leading edge slat with adjustable attitude of the present invention can adjust the attitude after the slat is installed, so as to ensure the aerodynamic gap requirements between the movable surface and the fixed surface, meet the interchangeability requirements, and ensure the zero position of the operating system. In addition, the attitude-adjustable leading-edge slat has a simple structure and is easy to adjust, which greatly reduces the difficulty of clearance control.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

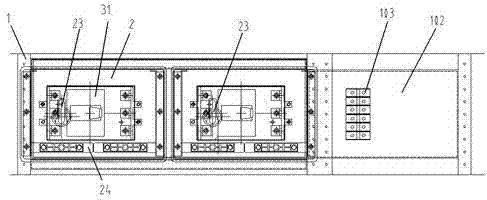

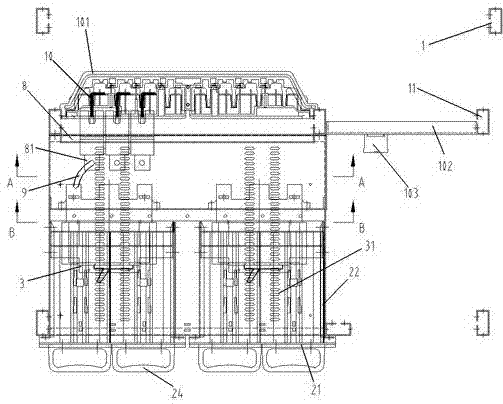

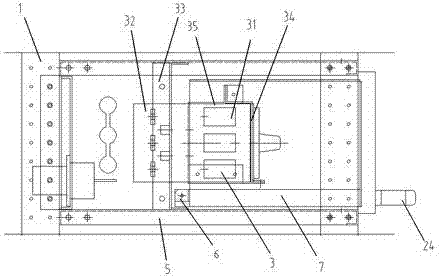

1/2 drawer unit for drawer type distribution cabinet

ActiveCN103001135BMeet the requirements of interchangeabilityReliable contactSwitchgear with withdrawable carriageEngineeringElectrical and Electronics engineering

Owner:镇江赛尔尼柯自动化股份有限公司

1553B bus network integration test method

InactiveCN111355621AImprove assembly reliabilityMeet the requirements of interchangeabilityLine-transmission monitoring/testingBus networksTester deviceNetwork integration

The invention discloses a 1553B bus network integration test method. The method comprises the steps: 1, carrying out preparation and offline, performing designing according to a bus network, accurately making a physical board model, placing all components according to actual requirements, enabling cables to be offline according to model requirements, enabling the trend of wiring harnesses to meetdesign requirements, and enabling an overlong whole section of cables to be allowed to be coiled; 2, identifying an end code, a bus code, a sub-line code and the like in the wire harness, so as to enable a bus network to be easy to perform feature identification in an installed environment or other environments; 3, assembling a connector in the bus network, wherein the connector comprises a sub-line connector and a 38999-series No.8 connector; 4, carrying out butt joint on the parts, needing to be switched over, of the buses and the parts, needing to be extended, of the sub-wires through wireconnectors, and mainly involving the crimping technology and the thermal shrinkage technology; and 5, testing the bus network subjected to the steps, and performing large-data-volume analog signal receiving and transmitting verification on the bus network from static and dynamic aspects by adopting a comprehensive network tester.

Owner:南京全信光电系统有限公司

mobile battery holder

InactiveCN102945938BMeet the requirements of interchangeabilityLow costCell component detailsElectrical batteryMetal sheet

The invention provides a movable battery holder which comprises a base and a metal sheet partially welded on the base, wherein the base comprises a working platform used for accommodating a battery, and a baffle plate arranged aslant above the working platform and connected with the working platform; and the metal sheet also comprises a first free end extending above the working platform and a second free end extending below the baffle plate. The movable battery holder can be independently produced together with a PCB (Printed Circuit Board), is assembled and combined with the PCB during use, can be independently replaced during replacement, meets the interchange requirement, and is saving in cost.

Owner:JIH VEI ELECTRONICS KUSN

Interchangeability design method for domestic satellite-mounted travelling-wave tube amplifier and imported satellite-mounted travelling-wave tube amplifier

ActiveCN102751153BMeet the requirements of interchangeabilityReasonable design methodTravelling-wave tubesTransit-tube coupling devicesSatellite dataAudio power amplifier

The invention provides an interchangeability design method for a domestic satellite-mounted travelling-wave tube amplifier and an imported satellite-mounted travelling-wave tube amplifier. The method comprises a step of mechanical interface interchangeability design, a step of input excitation interchangeability design and a step of usage pattern interchangeability design, wherein the step of mechanical interface interchangeability design comprises enabling installing interfaces of two travelling-wave tubes to be consistent with each other, be consistent with heat pipe layout interfaces positioned on a satellite structure boards and be consistent with antenna waveguide output interfaces; the step of input excitation interchangeability design comprises adjusting intensity of input excitation signals by externally connecting a fixed attenuator so as to meet the requirements of excitation of different saturation points of the two travelling-wave tubes; and the step of usage pattern interchangeability design comprises adding movement options of instructions such as starting / shutdown, feeding low pressure and discharging low pressure in operations schedule design so as to meet the requirements of two products for different usage patterns. According to the interchangeability design method, interchanging usage of the domestic travelling-wave tube amplifiers and the imported travelling-wave tube amplifier can be achieved, and flexibility in product matching in a subsystem scheme is guaranteed. The interchangeability design method is already applied in some satellite data transmitting subsystem.

Owner:SHANGHAI SATELLITE ENG INST

Semitrailer hinged-door production line

InactiveCN112025035AHigh precisionReduce labor intensityWelding accessoriesControl systemEngineering

The invention relates to a semitrailer hinged-door production line. The semitrailer hinged-door production line comprises conveying equipment, an assembling tool, a special welding robot, an automaticwelding machine and a control system, wherein the assembling tool is used for assembling parts such as door core veneers, vertical braces, transverse braces and square pipes, etc.; the special welding robot is adopted for spot welding positioning; the automatic welding machine is adopted for welding the door core veneers; and the control system is adopted to control the position and beat of eachstation node on the conveying equipment, so that the production line work is completed. The robot-operated intelligent automatic production line capable of achieving automatic pressure welding, automatic welding and standardized production of hinged door interchange belongs to intelligent manufacturing of traditional industry transformation and updating, and has the advantages that production automation and standardized organization production are achieved, produced workpieces completely meet the interchangeability requirement, and the workpiece precision is high; the labor intensity of staffis reduced, the production efficiency is improved by 100%, and manpower is saved by 70%; and the cost is reduced, and the operation environment is improved.

Owner:山东华耀汽车配件有限公司

Semitrailer portal frame production line

InactiveCN112025058AHigh precisionReduce labor intensityWelding accessoriesProduction lineControl system

The invention relates to a semitrailer portal frame production line. The semitrailer portal frame production line comprises conveying equipment, an assembling tool, a special welding robot and a control system, wherein the assembling tool is used for assembling parts such as door core veneers, front stand columns, bent parts, square pipes, etc.; the special welding robot is adopted for welding thedoor core veneers; and the control system is adopted to control the position and beat of each station node on the conveying equipment, so that the production line work is completed. The robot-operated intelligent automatic production line capable of achieving automatic pressure welding, automatic welding and standardized production of portal frame interchange belongs to intelligent manufacturingof traditional industry transformation and updating, and has the advantages that production automation and standardized organization production are achieved, produced workpieces completely meet the interchange requirement, and the workpiece precision is high; the labor intensity of staff is reduced, the production efficiency is improved by 100%, and manpower is saved by 70%; and the cost is reduced, and the operation environment is improved.

Owner:山东华耀汽车配件有限公司

Efficient CPU cooling fin

InactiveCN103425213AEasy to replaceDoes not affect connection strengthDigital data processing detailsEngineeringHeat sink

The invention discloses an efficient CPU cooling fin which comprises an I-shaped plate-shaped cooling fin body. A plurality of through holes are perpendicularly formed in the cooling fin body. The efficient CPU cooling fin is characterized in that at least two rods perpendicular to the upper surface of the cooling fin body are arranged on the upper surface of the cooling fin body, outer threads are arranged on each rod, the two rods respectively penetrate through a transverse board parallel to the cooling fin body, each rod is respectively connected with a first nut and a second nut, each first nut is located below the transverse board, and each second nut is located above the transverse board. A cooling tube is arranged between the cooling fin body and the transverse board, the height of the transverse board can be adjusted through adjustment of each second nut so that the heating tube can be clamped tightly. According to the clamping method, detachment is facilitated, when the cooling tube is damaged, the cooling tube is convenient to replace, the requirement for interchangeability is satisfied, and the phenomenon that the connecting strength is influenced by heat in other connecting modes of welding and the like is avoided.

Owner:KUNSHAN WEIJIN HARDWARE PROD

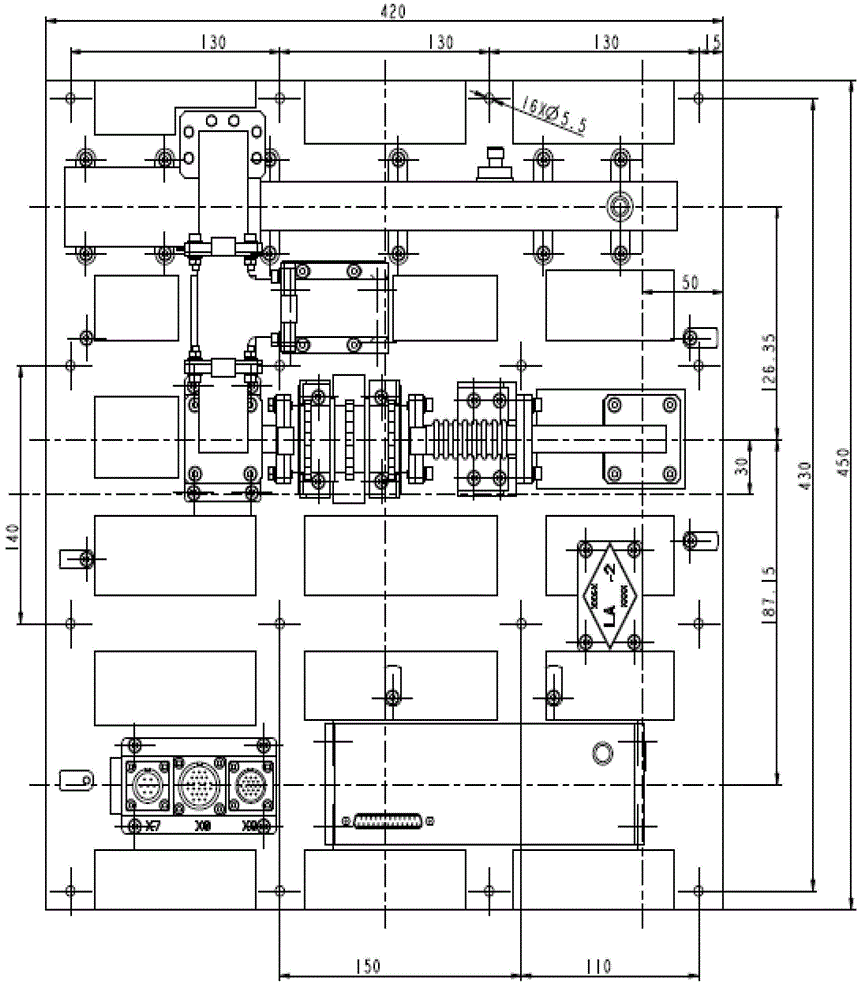

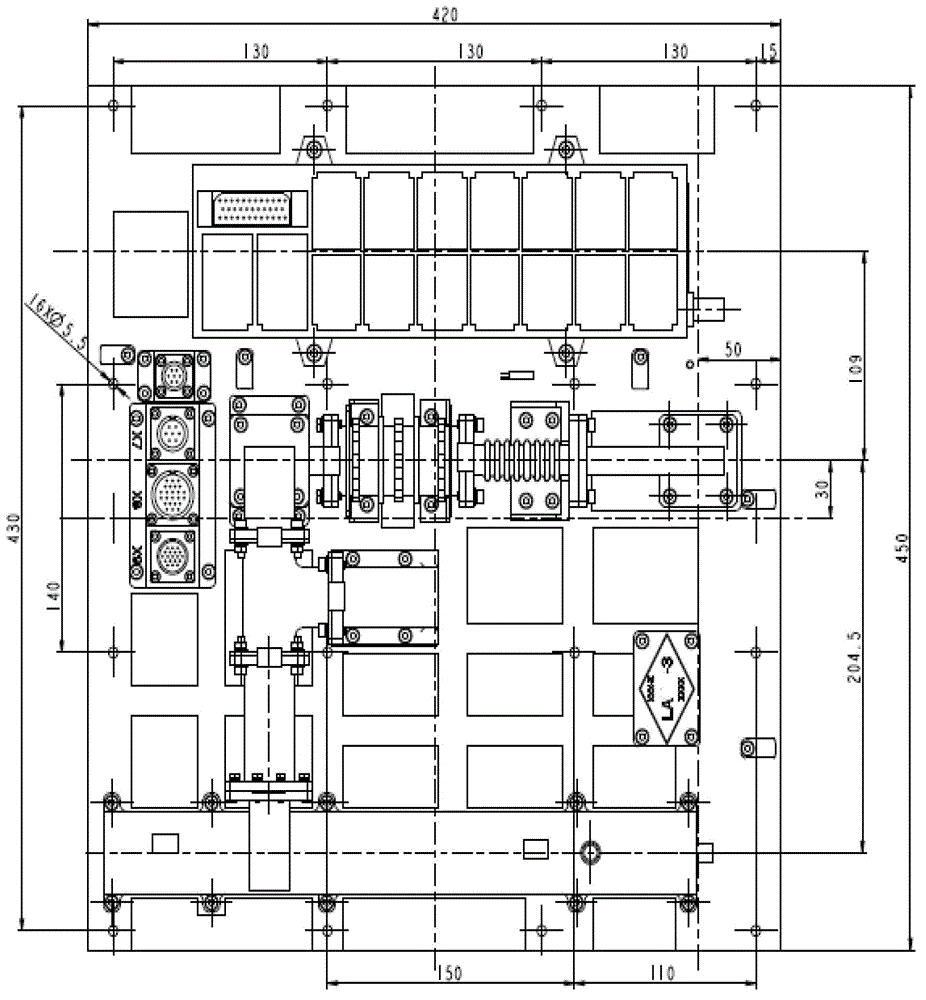

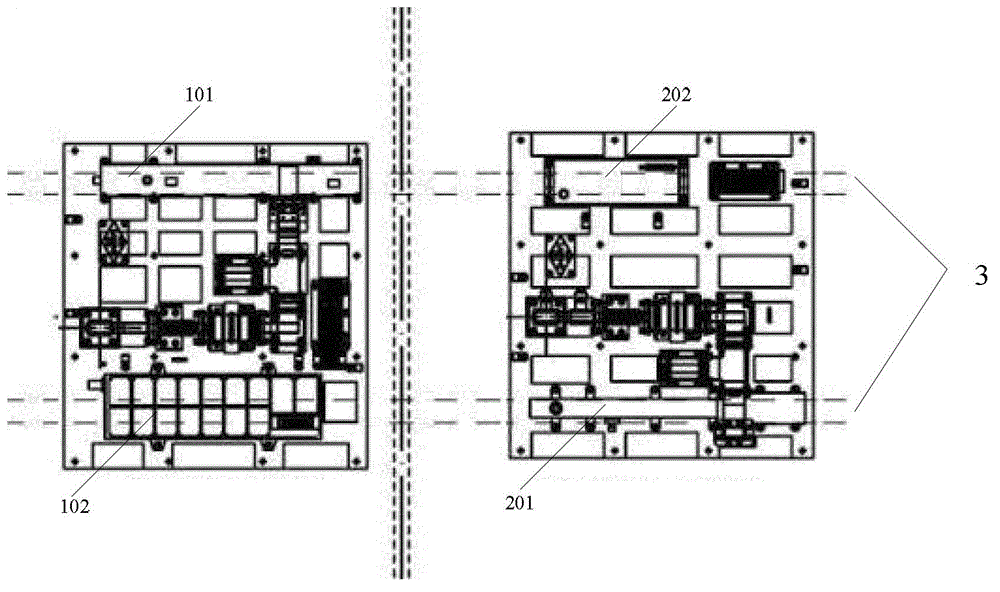

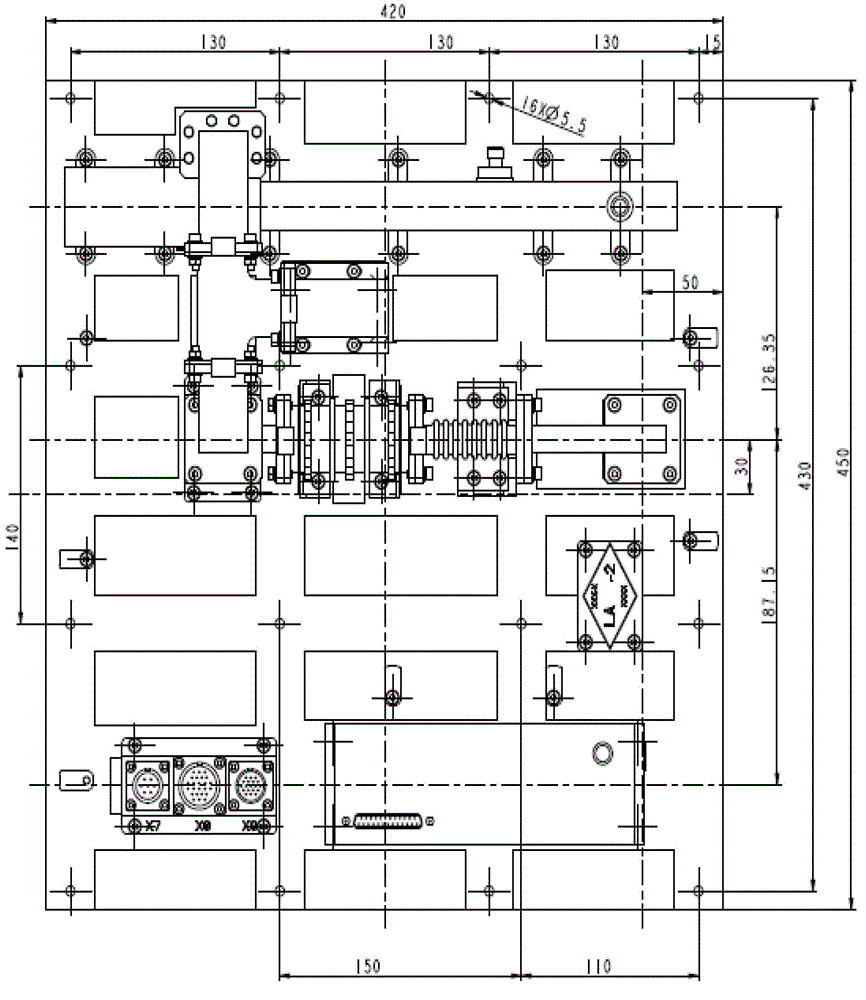

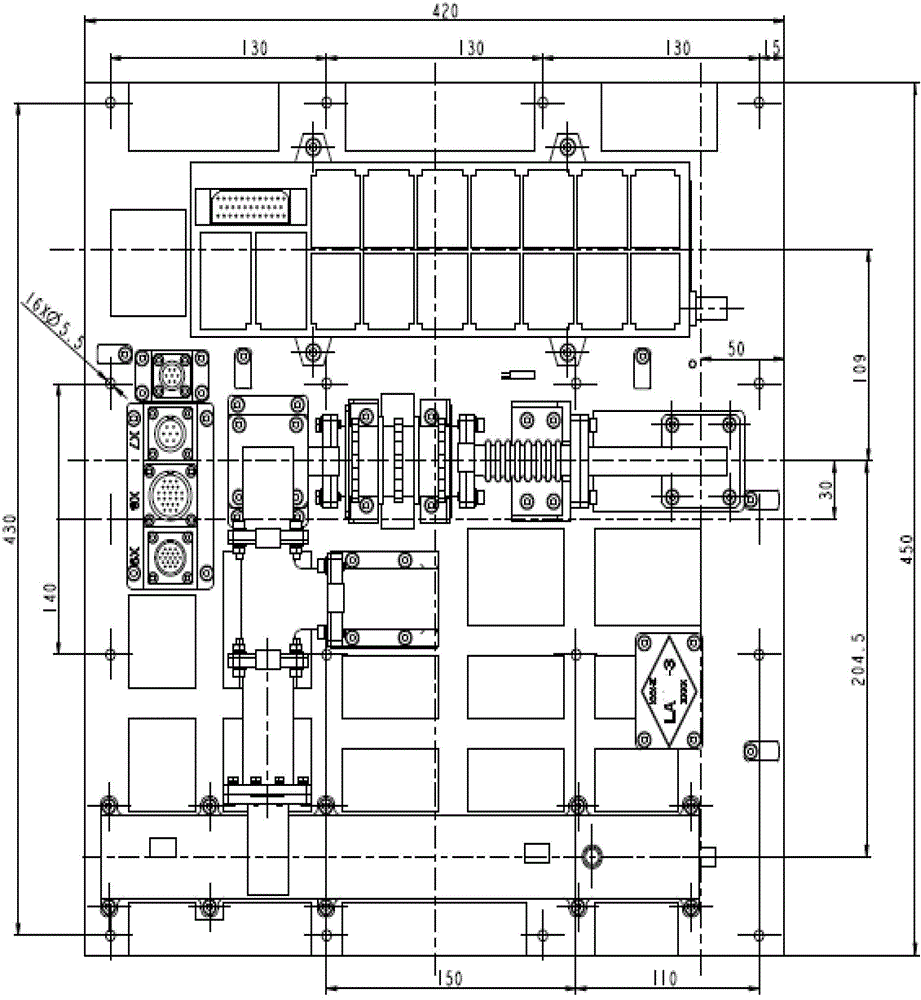

Overall assembly device for valve 120 module

Owner:CRRC MEISHAN

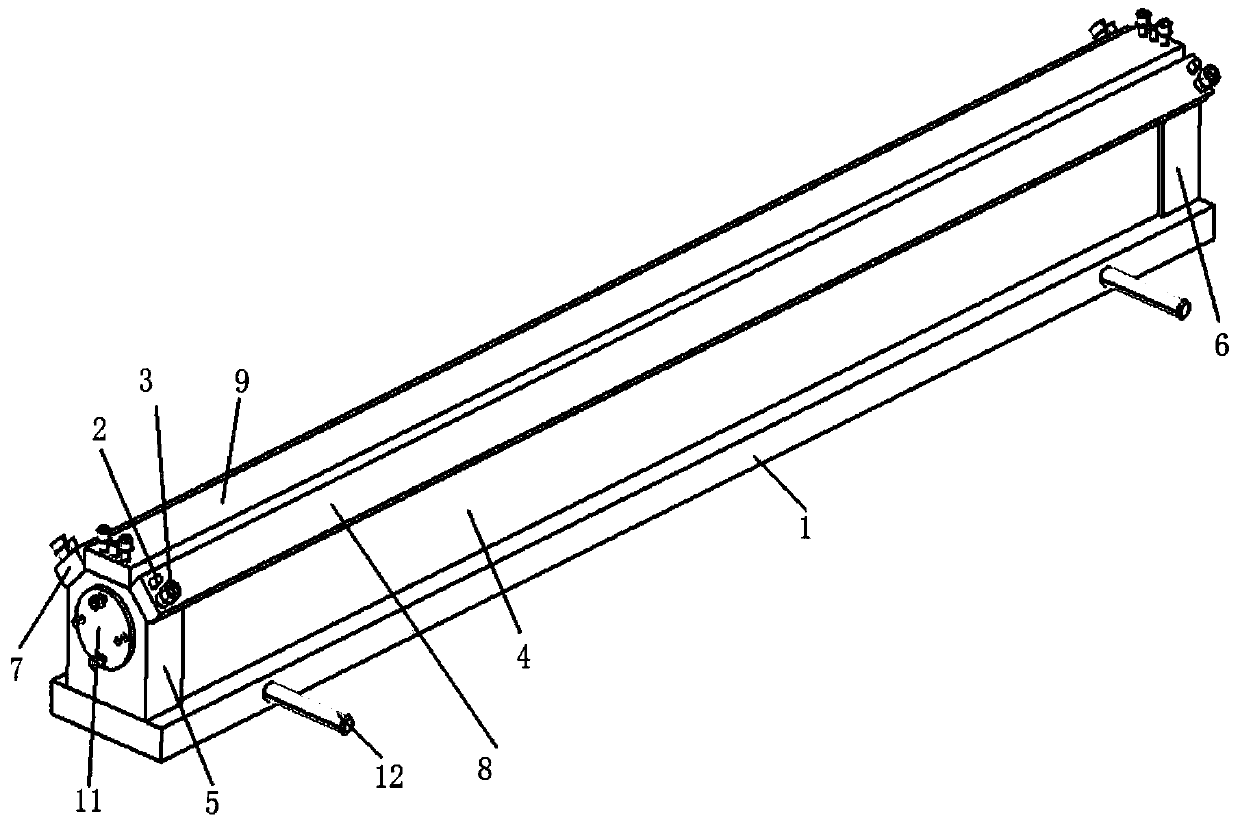

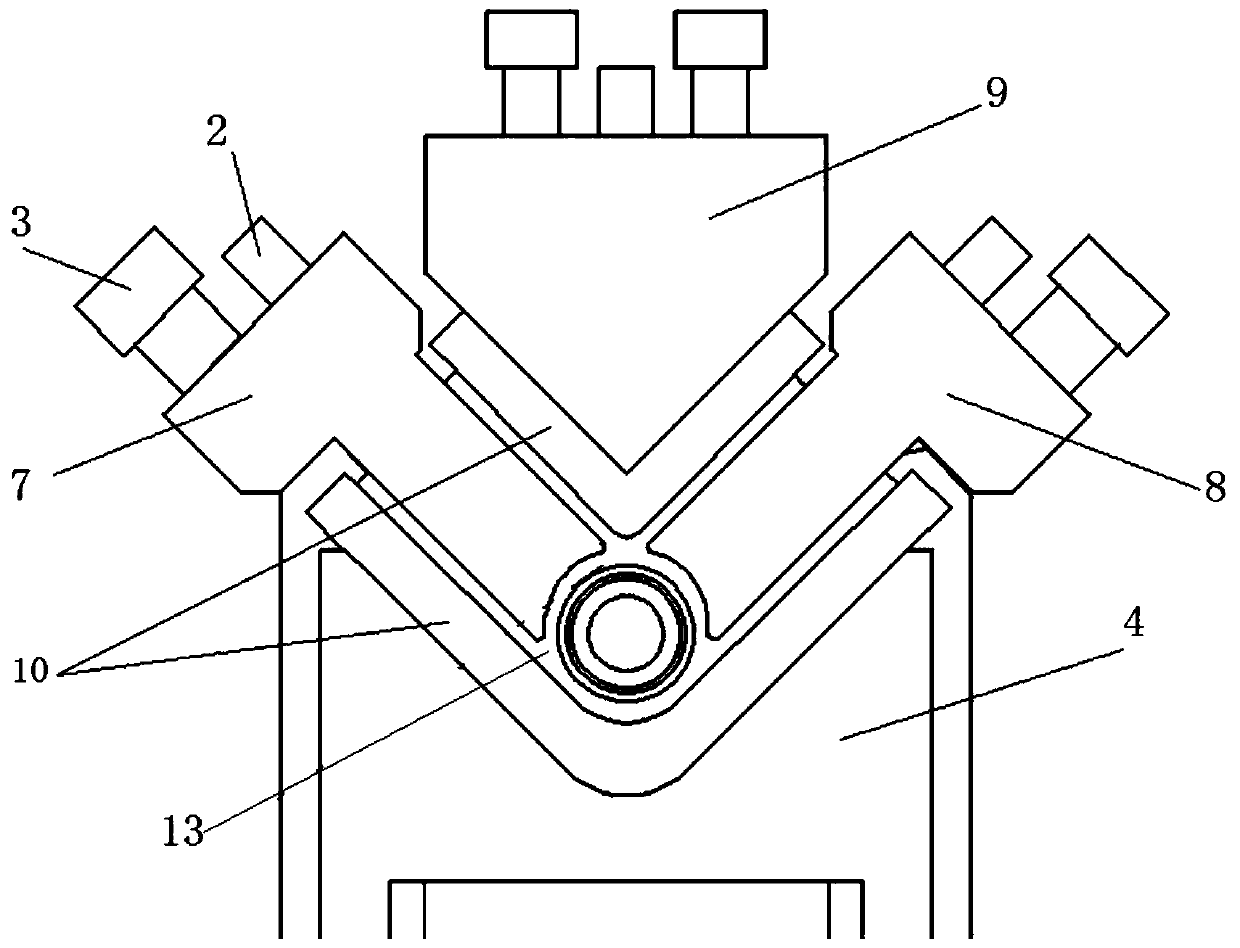

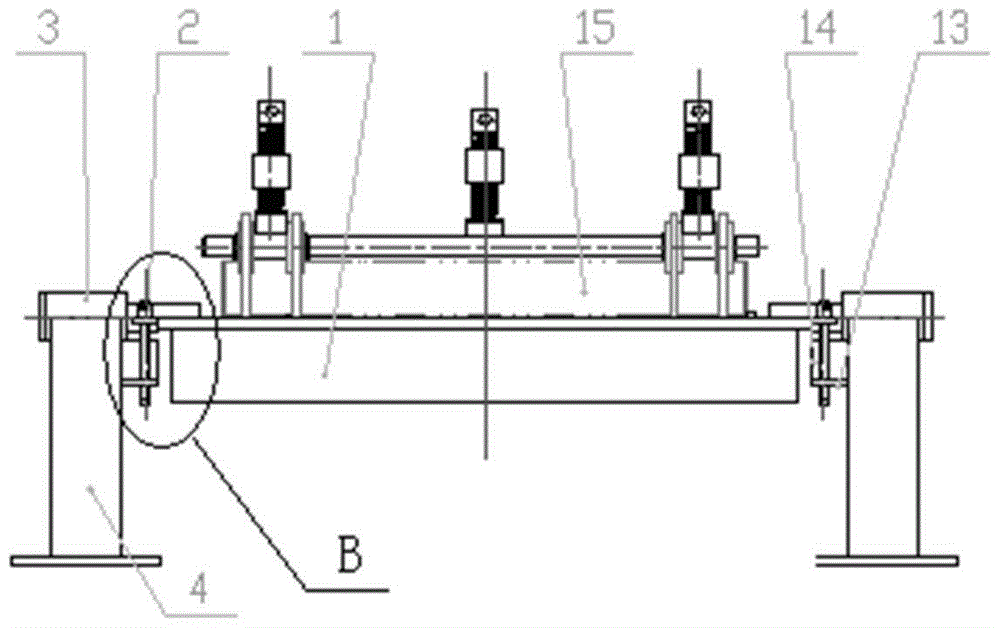

Transmission device of multi-working-condition intelligent batching system and control method

PendingCN113877469AGuaranteed parallelismReduce frictional resistanceTransportation and packagingMixer accessoriesControl theoryWire rope

The invention discloses a transmission device of a multi-working-condition intelligent batching system and a control method. The transmission device comprises a transmission support, a track walking frame, a rotary disc rotating assembly, a synchronous belt wheel and a belt wheel carrier. The track walking frame comprises a wheel carrier, and a plurality of walking wheels are rotatably arranged on the wheel carrier. The track walking frame abuts against a movement track (not shown) through the walking wheels, and the walking wheels are connected to the movement track in a rolling mode. The track walking frame is connected through a steel wire rope, a pressing plate is arranged on the upper side of the steel wire rope, and the pressing plate is fixedly connected with the wheel carrier through fixing bolts. Technical support is provided for realizing high-precision and rapid material injection of a multi-working-condition intelligent batching system. As sliding is replaced by rolling, friction resistance can be effectively reduced, and the precision of equipment is improved.

Owner:ZHEJIANG SCI-TECH UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com