Module-assembly welding fume dust remover

A dust collector and assembled technology, which is applied in transportation and packaging, chemical instruments and methods, and dispersed particle filtration, etc., can solve the problems of high maintenance and replacement costs, poor quality of the dust collector shell, and single use effect, so as to improve utilization efficiency, enhance consistency and interchangeability development, and reduce design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

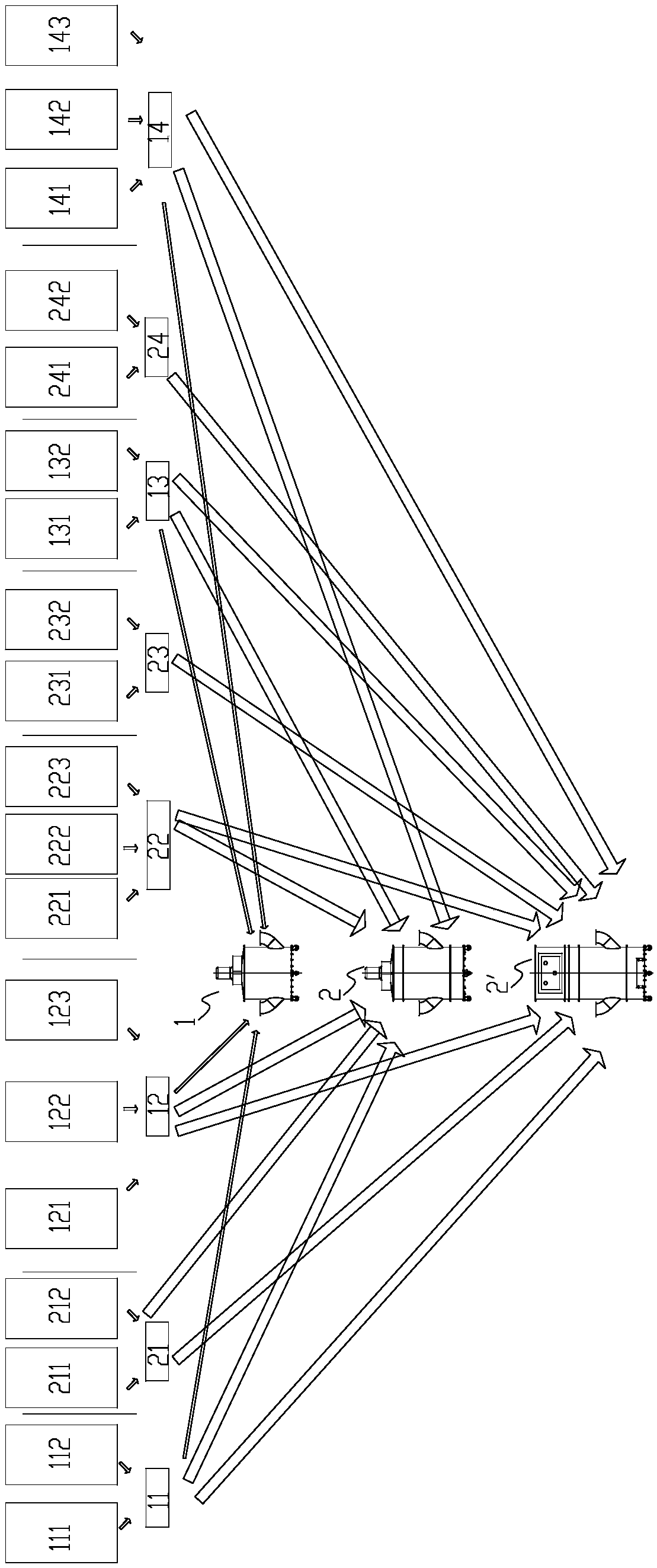

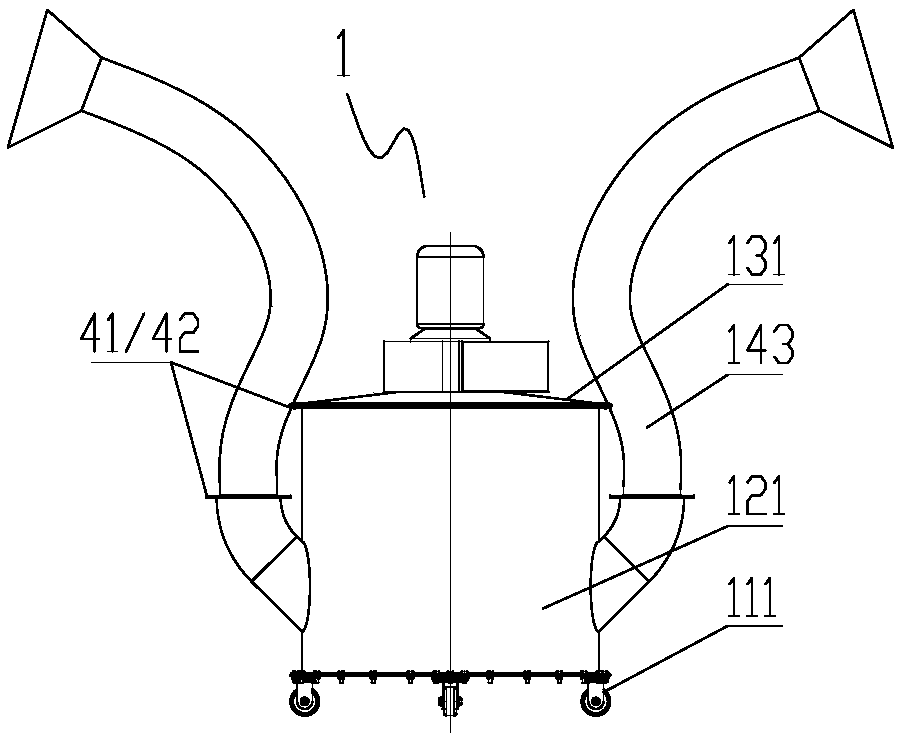

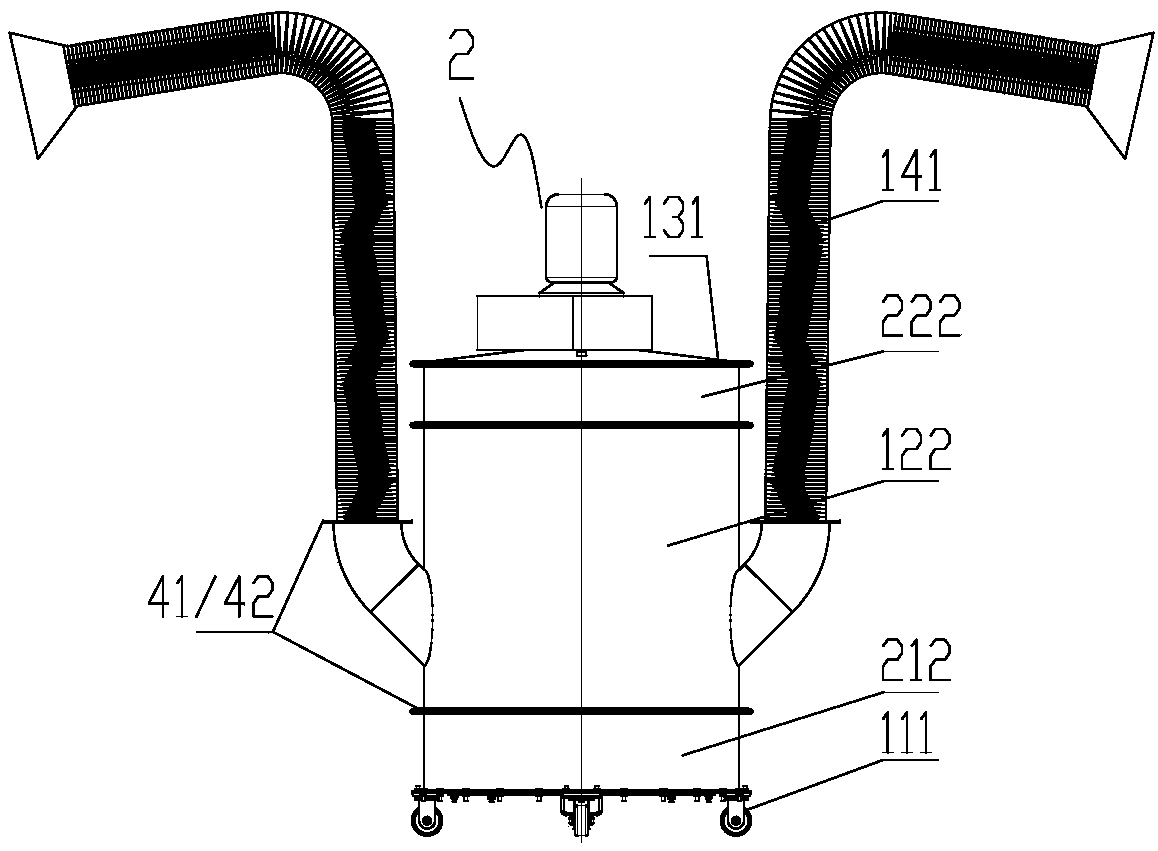

[0050] see figure 1, the three types of dust collectors in the figure are the basic dust collector 1, and the first dust collector 2 and the second dust collector 2' formed on the basis of the basic dust collector 1, wherein the basic dust collector 1 consists of a base Module 11, dust removal module 12, fan module 13 and suction arm module 14, the entire dust collector is fixed through the base module 11, the dust removal module 12 realizes the filtration of dust particles in the welding fume, and the fan module 13 provides a means for capturing the welding fume flow. Negative pressure, the suction arm module 14 realizes efficient collection of welding fume near the welding fume working point. The above four modules work together to achieve the basic function of the welding fume dust collector; the first dust collector 2 is in the basic dust collector. On the basis of 1, the dust collection module 21 and the backflushing module 22 are also selected. The dust collected by the ...

Embodiment 2

[0071] The classification and arrangement of the basic precipitator and the optional modules in this embodiment are the same as those in the first embodiment. The difference is that the two docking modules in this embodiment are connected by a rotary plug-in connection.

[0072] like Figure 5 and Image 6 As shown, between two docking modules, the two module cylinders 5 are inserted and connected, and the outer wall of one module cylinder is inserted into the inner wall of the other module cylinder to be docked, and the two module cylinders are inserted between the two module cylinders. The fixed locking is realized by the screw locking structure. Specifically, protrusions are provided on the outer and inner walls of the two butt-jointed modular cylinder bodies 5 that are in contact with each other. The two module cylinders 5 are rotated relative to each other, and the axial movement between the two module cylinders 5 is realized through the inclined surface with the helix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com