Flange quick-changing drill jig

A drilling jig and flange technology, applied in the field of machinery, can solve problems such as difficult positioning of water pump flanges, and achieve the effect of meeting the needs of large-scale production, simple and fast operation, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

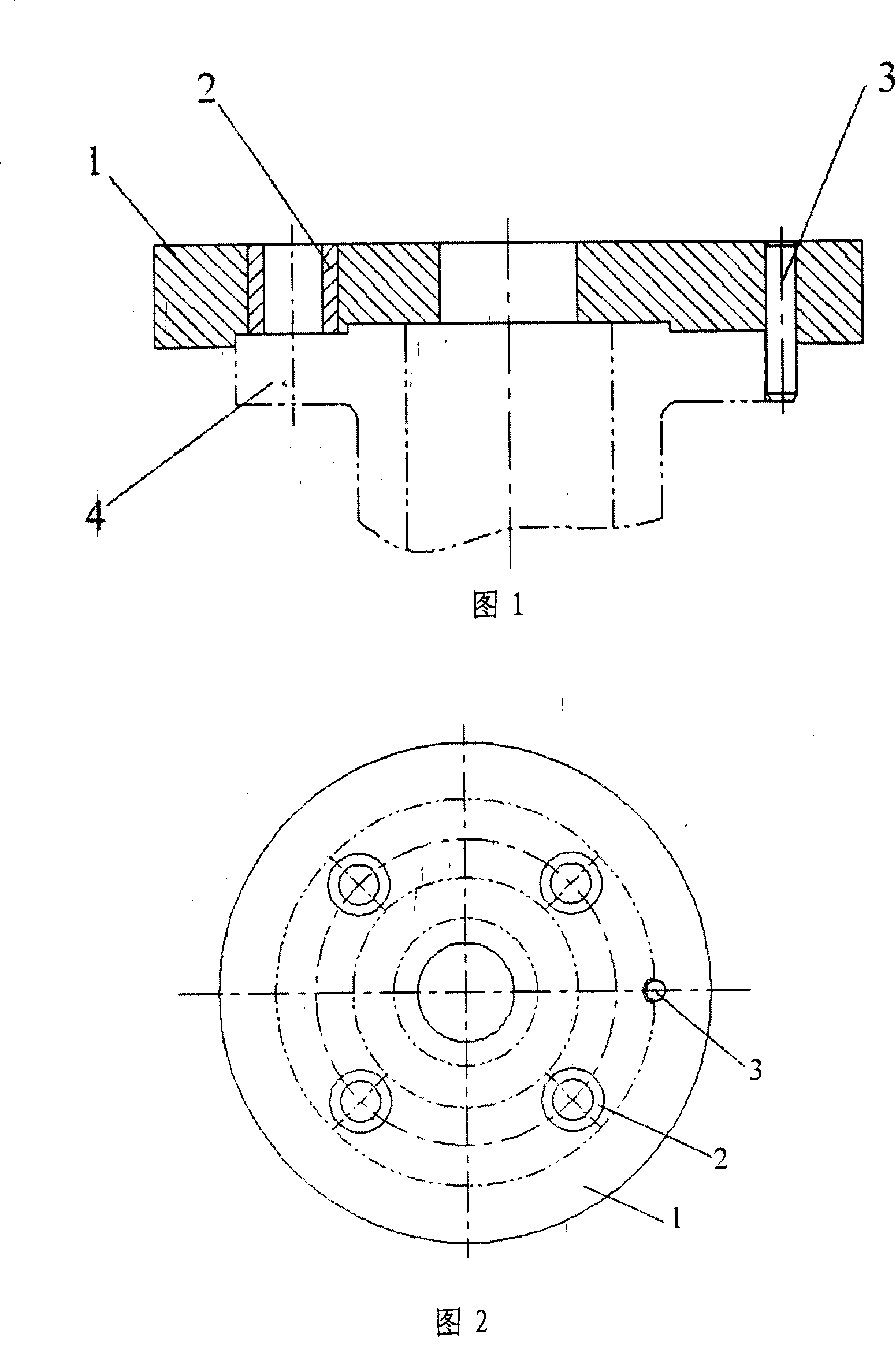

[0012] As shown in Figures 1 and 2, the flange quick-change drill die of the present invention is composed of a metal disc member 1, wherein the metal disc member 1 is provided with a plurality of through holes, and any one of the The axial direction of the through hole is parallel to the axial direction of the metal disc member 1, and a drill sleeve 2 is fixedly arranged in any through hole, and any one of the drill sleeves 2 is a cylindrical tubular member, and the metal disc member At least one positioning pin hole is provided in 1.

[0013] Further, a positioning pin 3 is provided in the positioning pin hole.

[0014] Further, the diameter of the positioning pin is 8 mm.

[0015] Further, four drill sleeves 2 are provided in the metal disc member 1.

[0016] The working principle of the present invention is: a circular arc notch is cast on the blank 4 of the flange to be processed, the metal disc member 1 is placed on the end face of the flange during processing, and the posit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com