Semitrailer boxboard production line

A production line, semi-trailer technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of arc light, smoke and dust, unstable welding quality, high labor intensity, etc., and reduce labor intensity. , the effect of saving manpower and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further details and effects of the invention are explained in more detail below by means of different illustrative embodiments shown in the drawings. The embodiments described by referring to the figures are exemplary for the purpose of explaining the present invention and should not be construed as limiting the present invention.

[0018] The box board composition of semi-trailer box board production line output of the present invention, see Figure 6 , comprising a vertical piece, a horizontal piece and a core plate, the duckbill in the middle of the vertical piece clamps the core plate, the notches at both ends of the vertical piece are connected to the horizontal piece, and the horizontal piece is fixedly connected to the core plate. Among them, the shape of the vertical edge is shown in Figure 7 , the middle part is a duckbill structure, and the two ends are notches.

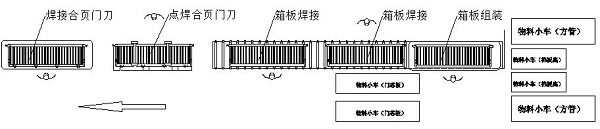

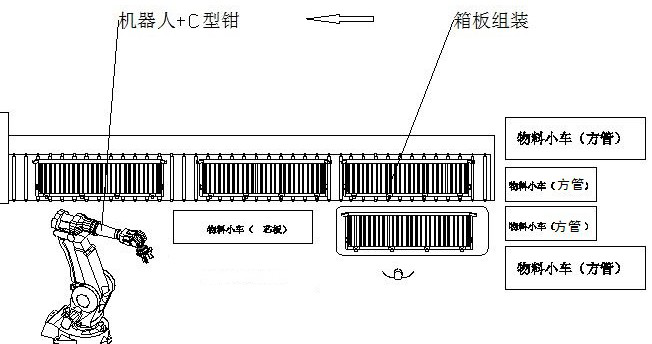

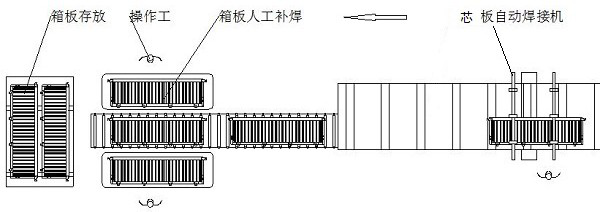

[0019] An embodiment of a semi-trailer box plate production line, according to figure 2 , 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com