Middle wing part gluing and folding tool for small and medium-sized unmanned aerial vehicles

An unmanned aerial vehicle, small and medium-sized technology, which is applied in the field of closing and tooling of mid-wing parts of small and medium-sized unmanned aerial vehicles, and can solve the problems of low positioning accuracy of aircraft joint parts, low aircraft airfoil accuracy, and inability to guarantee the quality of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

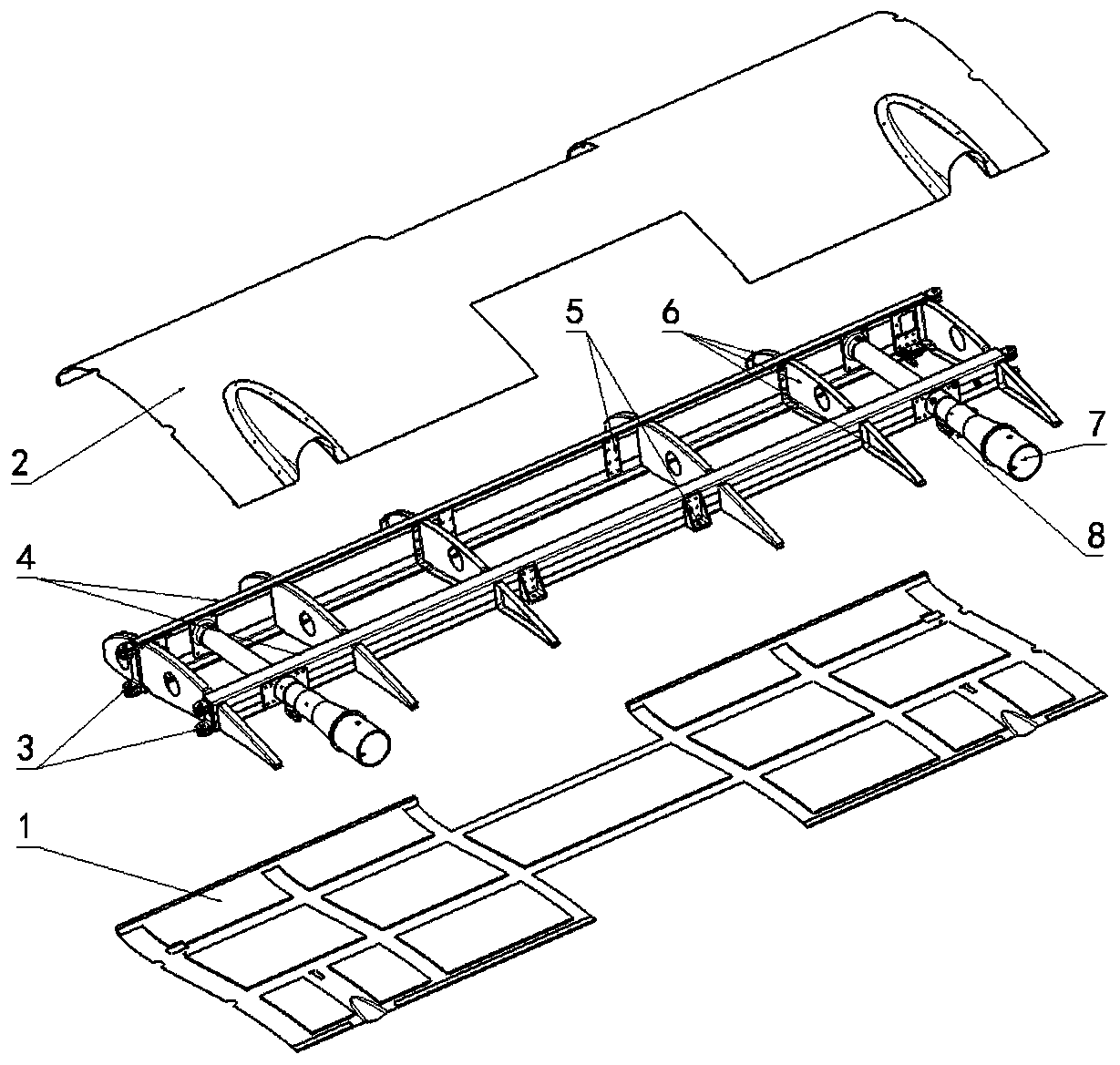

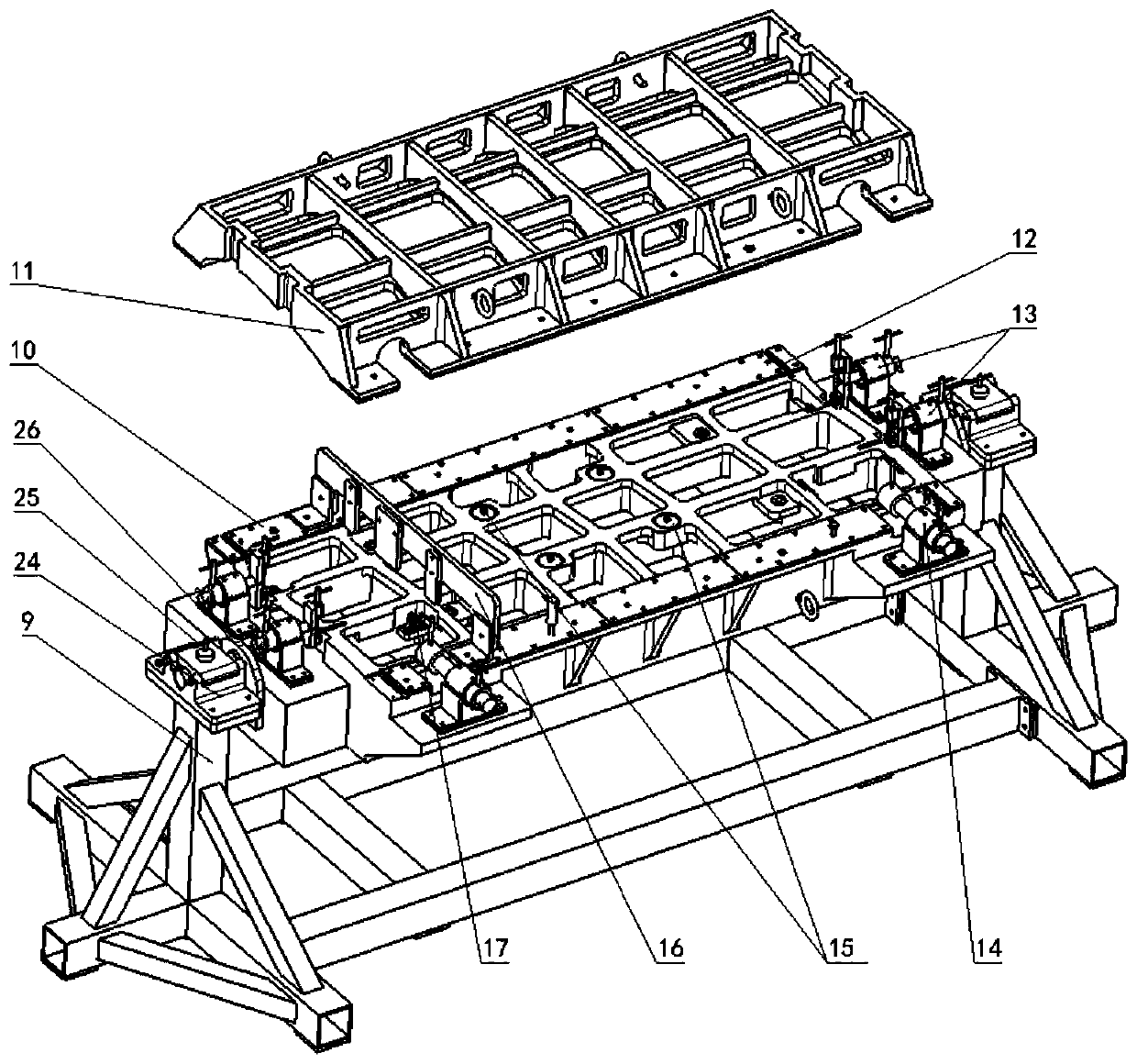

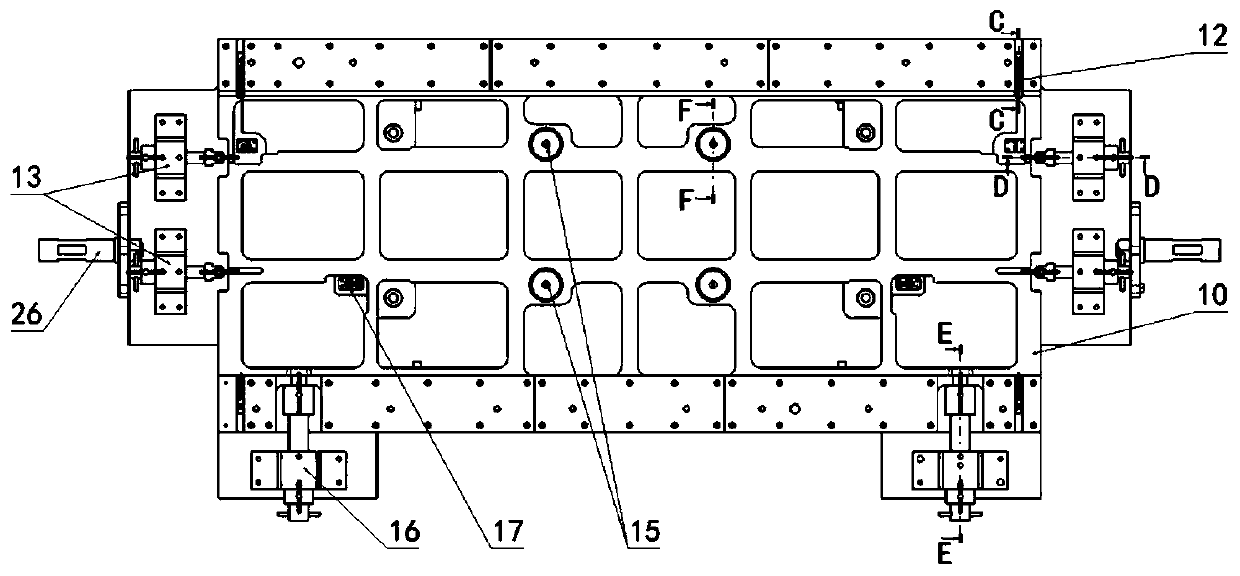

[0023] This embodiment is a glued and stitched tooling for wing parts in a small and medium-sized unmanned aerial vehicle.

[0024] refer to Figure 1 to Figure 7 , the present embodiment is designed with the wing component parameter target in a certain type of unmanned aerial vehicle:

[0025] Main parameter list of mid-wing components of a UAV

[0026]

[0027] In this embodiment, the raw material of the base and the pressure frame is ZL101, and the heat treatment adopts quenching and artificial aging; the raw material of the locator that is often inserted and pulled out is 30CrMnSiA, HRC30-35; other materials are selected from Q235; the positioning and fasteners are selected from national standards.

[0028] In this embodiment, the glued joint tooling of the middle wing parts of the UAV consists of a rotating bracket 9, a base 10, and a pressure frame 11. A horizontal measurement point locator 12, a front and rear joint locator 13 of the middle wing, and a tail support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com