Drilling deviation rectification method for 60-meter-long hole drilling of tunnel large pipe shed

A technology for large pipe sheds and tunnels, applied in directional drilling and other directions, can solve problems such as the inability to guarantee the position and direction of the drilling, the quality of the drilling, and many uncertain factors, so as to shorten the construction period and ensure the quality of the drilling. , the effect of reducing the number of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

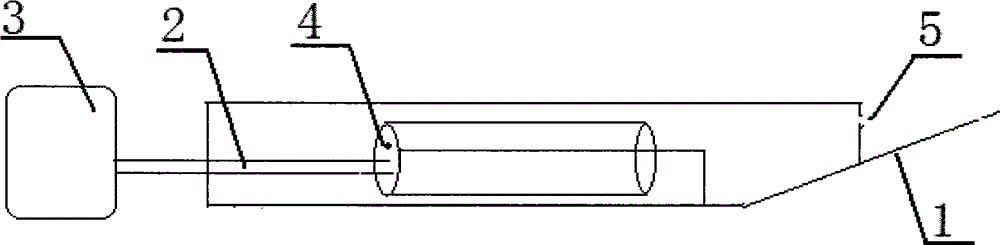

[0021] The drilling deviation correction method used in the drilling of large pipe sheds in 60-meter-long tunnels, the specific operations are:

[0022] The orientation of the roll angle and the deflection azimuth of the drill bit are monitored by the guide probe installed at the back of the drill bit (the guide probe is a conventional structure, which is sold in the market, so I won’t repeat it), and then through the signal line passing through the drill pipe of the drilling rig 2. Connect to the display screen 3 located on the drilling rig console. The display screen 3 displays the inclination angle of the drill bit, which is the horizontal angle, and the roll angle, which is the direction of the guide plate 1. The direction of the guide plate 1 is 12 o’clock when the guide plate faces upward, just like a clock face;

[0023] Adjust the drilling direction according to the inclination angle and face angle of the drill bit displayed on the display screen 3, and adjust the wedge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com