Method for sorting and separating ore from aluminum silicon mineral

A mineral, aluminum-silicon technology, applied in the direction of solid separation, flotation, etc., can solve the problems of large chemical consumption per unit of selected ore, difficult tailings settlement, and low classification efficiency, so as to facilitate settlement and product dehydration, fine ore concentrate Particle size reduction, the effect of saving grinding energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The low-grade bauxite in Jinnan, Shanxi Province was used as the test sample. The chemical composition is shown in Table 1, and the mineral composition is shown in Table 2.

[0023] Table 1 Chemical composition of low-grade bauxite in Jinnan, Shanxi

[0024] chemical composition

[0025] Table 2 Mineral phase composition of low-grade bauxite in Jinnan, Shanxi

[0026] Phase

[0027] Process equipment: The first stage grinding adopts grid type ball mill, the roughing equipment is micro-bubble flotation machine, the second stage grinding adopts overflow type grinding machine, and the grading equipment is hydrocyclone.

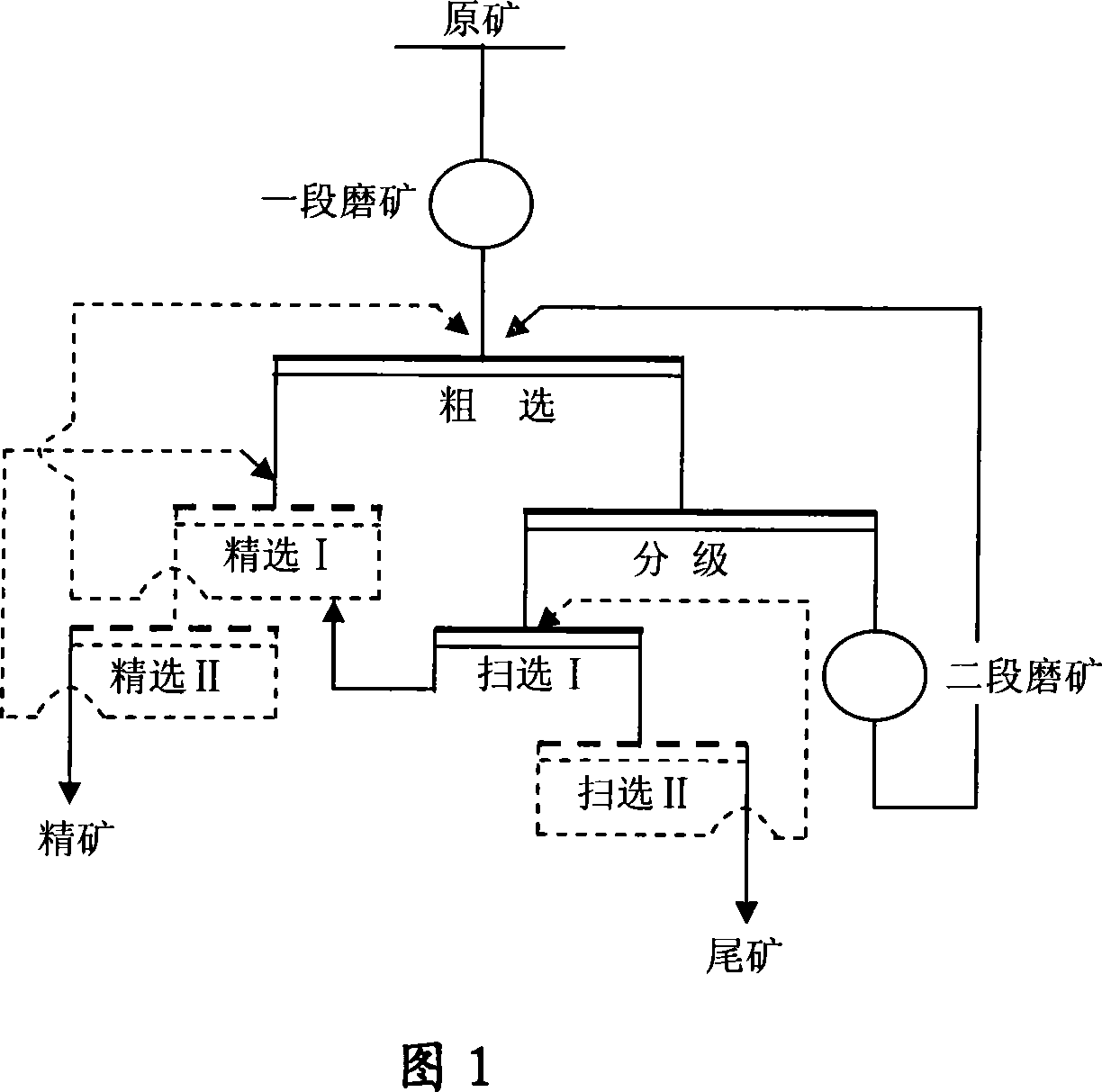

[0028] Technological process: see the process principle flow chart (attached drawing 1), using two selections and two screening processes.

[0029] Process parameters: The fineness of the first stage grinding is 40.7%, the fineness of the second stage grinding is 65.5%, the graded fineness -0.074mm content is 98%, and the reagent syste...

Embodiment 2

[0039] The low-grade bauxite in Shanxi Jinnan was used as the test sample, and the properties of the sample are shown in Table 1 and Table 2.

[0040] Process equipment: The first stage of grinding adopts a grid type ball mill, the roughing equipment is an inflatable mechanical agitation flotation machine, the second stage of grinding adopts an overflow type grinding machine, and the high-efficiency classification equipment is a hydrocyclone.

[0041] Technological process: see the process principle flow chart (attached drawing 1), using two selections and two screening processes.

[0042] Process parameters: The fineness of the first stage grinding is 77.23%, the fineness of the second stage grinding is 88.69%, the content of the high-grade fine-grained grade -0.074mm is 90.0%, and the chemical system is a conventional positive flotation chemical system.

[0043] Process indicators: see Table 5.

[0044] Table 5 Flotation index of Example 2

[0045] product

[00...

Embodiment 3

[0052] The low-grade bauxite in Shanxi Jinnan was used as the test sample, and the properties of the sample are shown in Table 1 and Table 2.

[0053]Process equipment: The primary grinding adopts a grid type ball mill, the roughing equipment is a flotation column, the secondary grinding adopts an overflow type grinding machine, and the grading equipment is a vibrating screen.

[0054] Technological process: see the process principle flow chart (attached drawing 1), using two selections and two screening processes.

[0055] Process parameters: The fineness of the first stage grinding is 62.4%, the fineness of the second stage grinding is 71.23%, the graded fineness -0.074mm content is 95%, and the reagent system is the conventional positive flotation reagent system.

[0056] Process indicators: see Table 7.

[0057] Table 7 Flotation index of Example 3

[0058] product

[0059] The concentrate was screened and analyzed, and the results of the screen analysis are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com