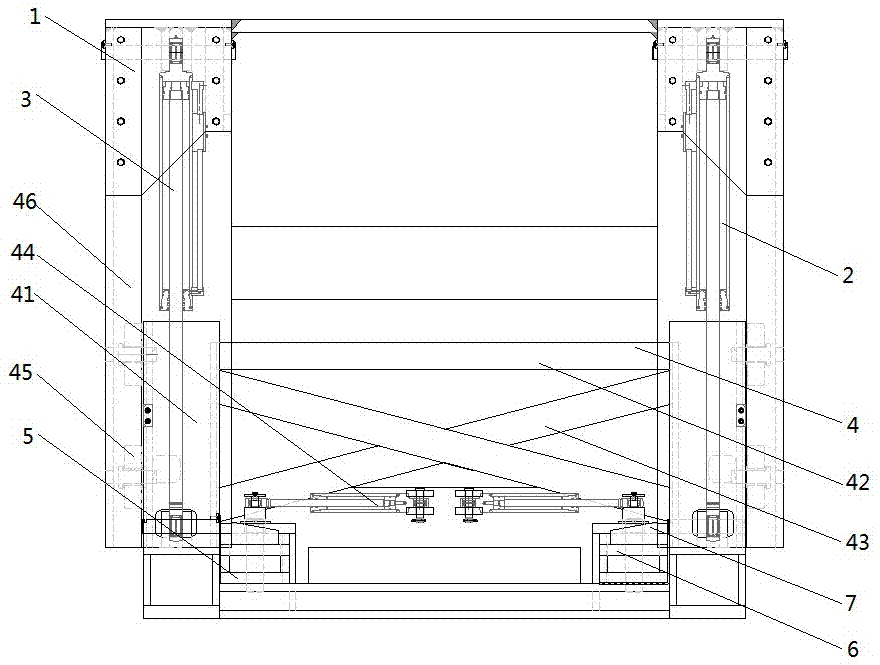

Shield tunneling machine duct piece quick dismantling device

A technology of unloading device and shield machine, which is applied to shaft equipment, shaft lining, tunnel lining, etc., can solve problems such as low construction efficiency and potential safety hazards, and achieve the goal of improving construction efficiency, simple structure, and ensuring segment transportation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

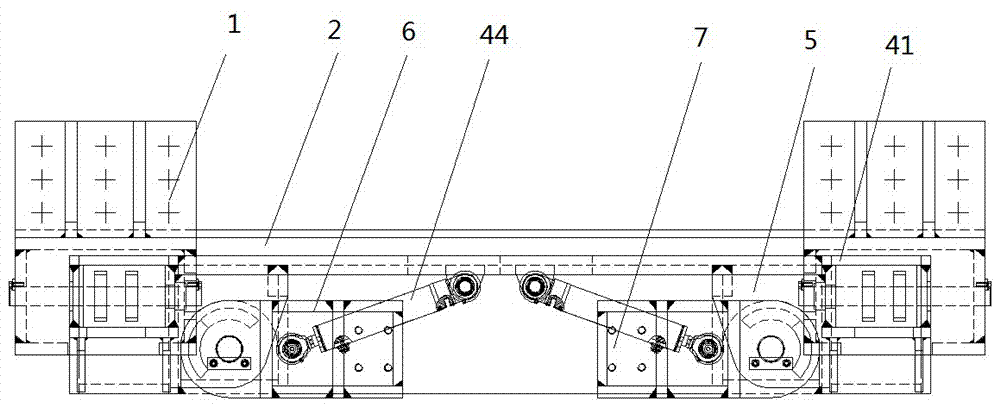

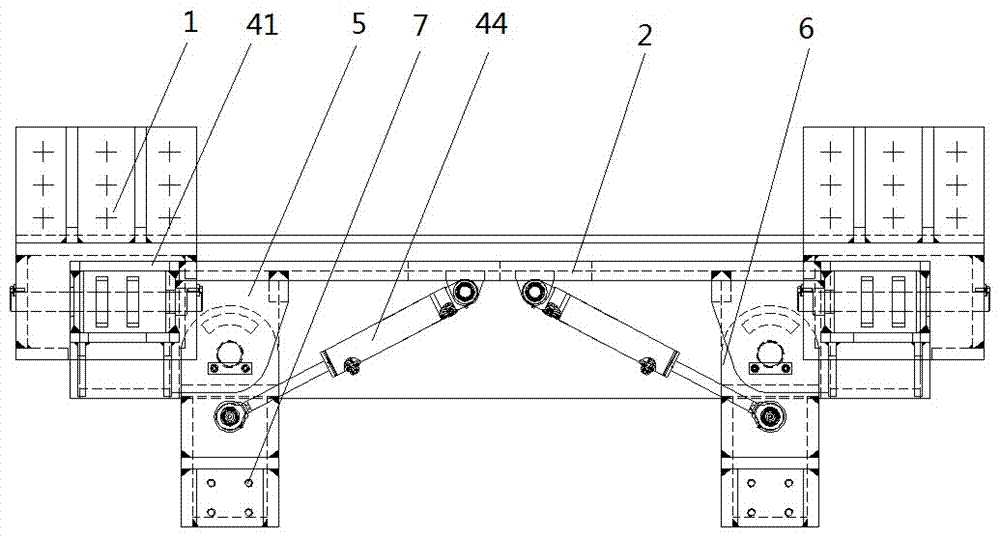

[0029] Embodiment 2, the support base 6 is provided with a position relay group connected to the single-chip controller, the position relay group is also connected with the driver of the telescopic oil cylinder 44, and the position relay group includes a 90-degree dynamic-off type relay and a 0-degree dynamic-off type For the relay, the 90-degree dynamic-off relay is arranged on the left side of the turntable 5, and the 0-degree dynamic-off relay is arranged on the rear side of the turntable 5. The coils of the 0-degree dynamic-off relay and the 90-degree dynamic-off relay are in contact The heads are all facing the support seat. When the support seat 6 does not touch the external contact of the position relay group, the working circuit of the telescopic oil cylinder continues to conduct, and the telescopic oil cylinder continues to move; when the support seat 6 contacts the coil external contact of the position relay group, the telescopic oil cylinder When the working circuit ...

Embodiment 3

[0030] In embodiment 3, the hydraulic cylinder 3 is a jacking cylinder and there are two jacking cylinders. The two jacking cylinders are respectively vertically arranged on both sides of the lifting frame 1. The sliding frame is a rectangular frame, and the rectangular frame includes vertical beams, The crossbeam and the inclined beam connected inside the rectangular frame, the vertical beam is a square steel with a closed upper port, the base of the jacking cylinder is fixedly connected to the bottom of the lifting frame, and the end of the telescopic cylinder of the jacking cylinder passes through the square steel The formed channel is connected to the upper port of the square steel. The hydraulic cylinder is designed as a jacking cylinder connected to the upper end of the sliding frame, even if the segment is lifted by jacking, the hydraulic cylinder with the same pressure can provide greater force than the jacking method, so the jacking method is used The mechanical prope...

Embodiment 4

[0032] In Embodiment 4, a displacement sensor connected to the telescopic oil cylinder is installed instead of the position relay group, and the telescopic movement of the telescopic oil cylinder is controlled by the displacement sensor, thereby controlling the precise rotation of the support seat to a specific position. The movement of the support seat can be controlled more precisely by using the displacement sensor, so that the lifting of the segment by the support seat is more stable and reliable. Other structures of this embodiment are the same as Embodiment 1.

[0033] The working process of a shield machine segment fast unloading device of the present invention is as follows: when the segment transport trolley 11 driven by the muck transport vehicle is about to leave the tunnel 12, the segment transport trolley 11 stays on the shield machine segment of the present invention Between the lifting racks of the quick unloading device, after starting the device, the support s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com