Use of konjac glucomannan in changing fresh-water fish protein frozen denaturation and minced fish meat texture characteristics and minced fish meat water-retention property

A konjac glucomannan and freshwater fish technology, applied in the field of konjac glucomannan, can solve the problems of affecting product taste, reprocessing performance consumer groups, high calorie, heavy sweetness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

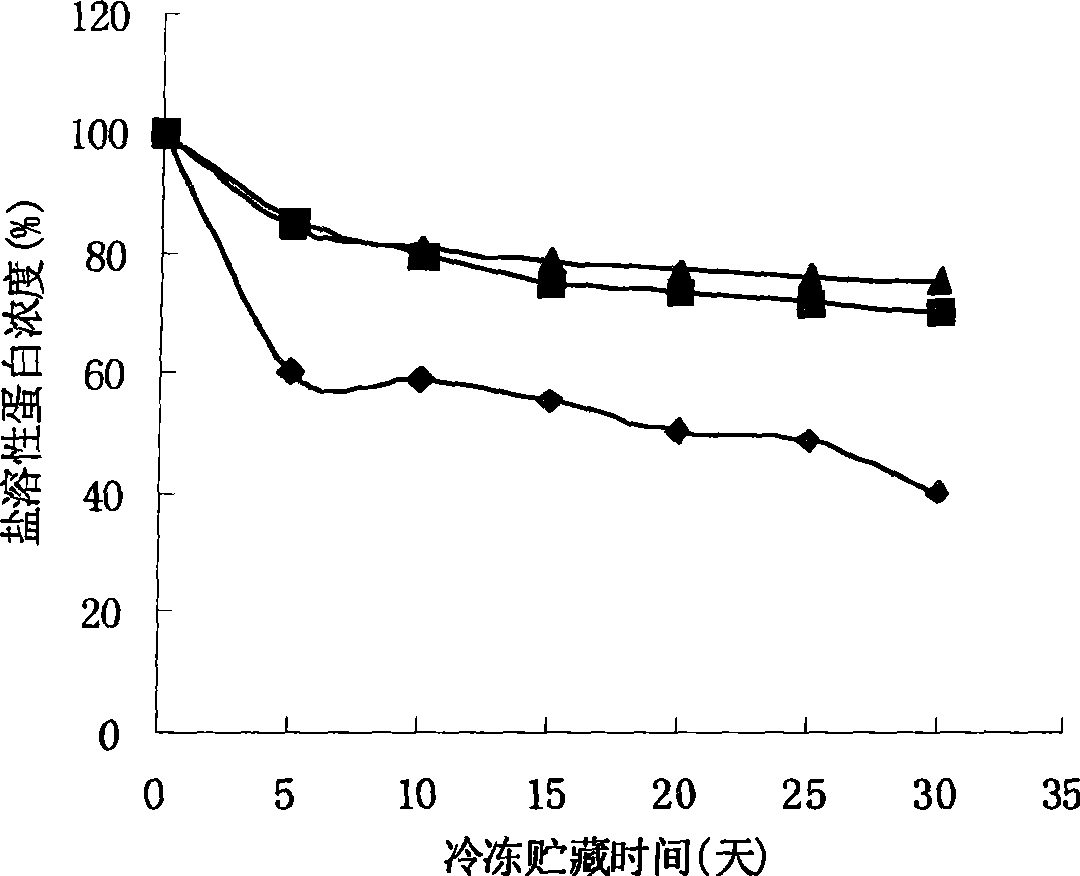

[0017] Example 1. Changes in salt solubility of myofibrillar protein during frozen storage:

[0018] Salt solubility changes of freshwater fish myofibrillar protein during frozen storage figure 1 As shown, the group with round blocks in the line is the control group, the group with square blocks in the line is the sucrose sorbitol group, and the group with triangular blocks in the line is the konjac glucomannan group.

[0019] It can be clearly seen from the figure that there is a significant difference between the change of salt solubility of myofibrillar protein in the control treatment and the treatment of adding antifreeze. With the extension of frozen storage time, the content of salt-soluble protein in all processed samples showed a downward trend. The control group decreased rapidly at the beginning of frozen storage. After 5 days of frozen storage, the salt-soluble protein content dropped to 60.1%, and then the rate of decline slowed down until 30 days of frozen stora...

Embodiment 2

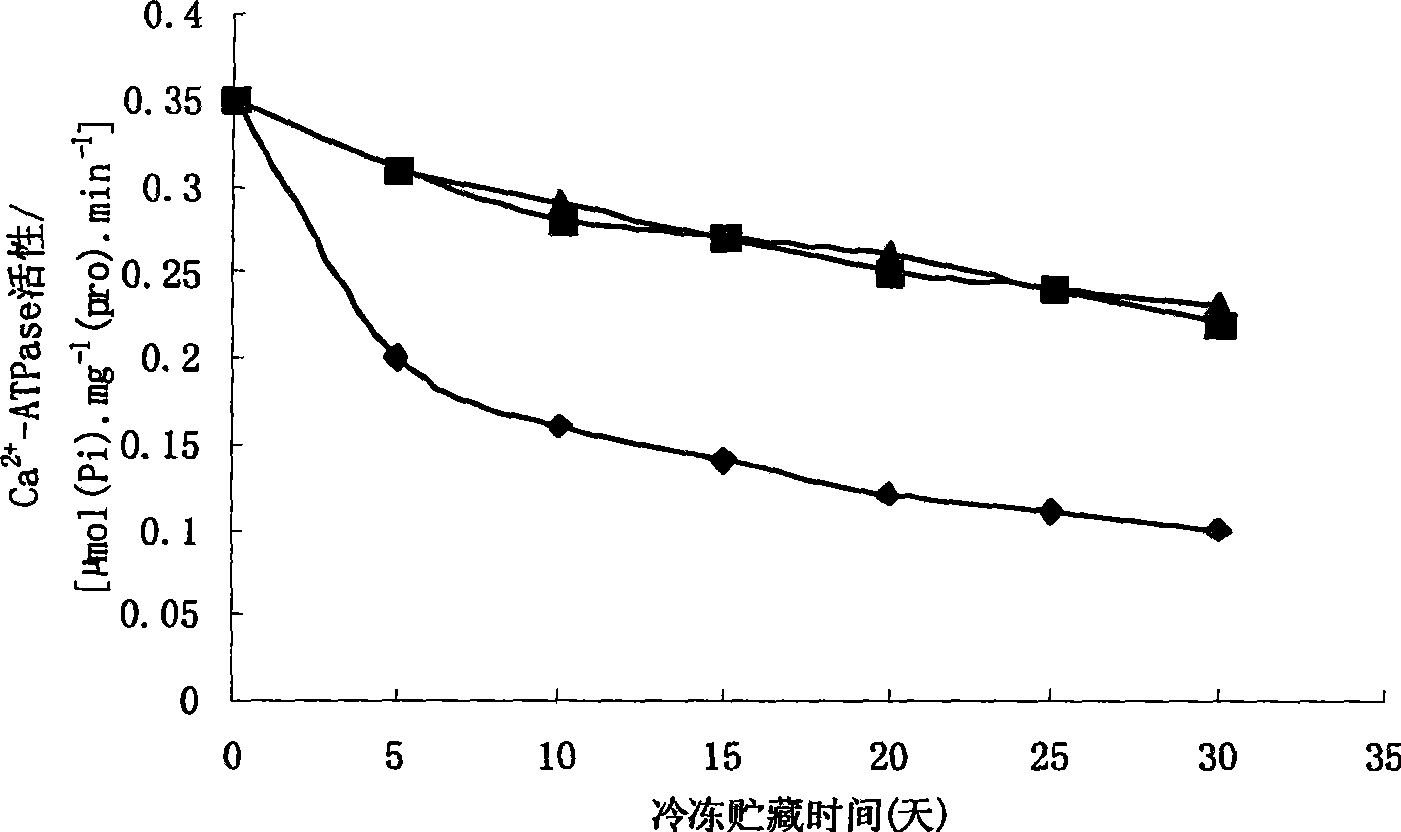

[0020] Myofibrillar protein Ca in embodiment 2, frozen storage process 2+ —Change in ATPase activity

[0021] Myofibrillar protein has ATPase activity, which will change due to protein denaturation during freezing storage. Therefore, the ATPase activity of myofibrillar protein is widely used as an indicator of fish meat or surimi protein denaturation. protein Ca 2+ —The change curve of ATPase activity figure 2 , it can be seen from the figure that the control treated myofibrillar protein Ca 2+ — There was a significant difference between the change of ATPase activity and the treatment of adding antifreeze. At the beginning of frozen storage, the enzyme activity of the control treatment decreased rapidly, and after 5 days of frozen storage, the enzyme activity increased from 0.35μmol(Pi).mg -1 (pro).min -1 down to 0.2μmol(Pi).mg -1 (pro).min -1 , decreased by 42.8%, and decreased to 28.6% of the initial value when frozen for 30 days. Antifreeze-treated Ca 2+ —The red...

Embodiment 3

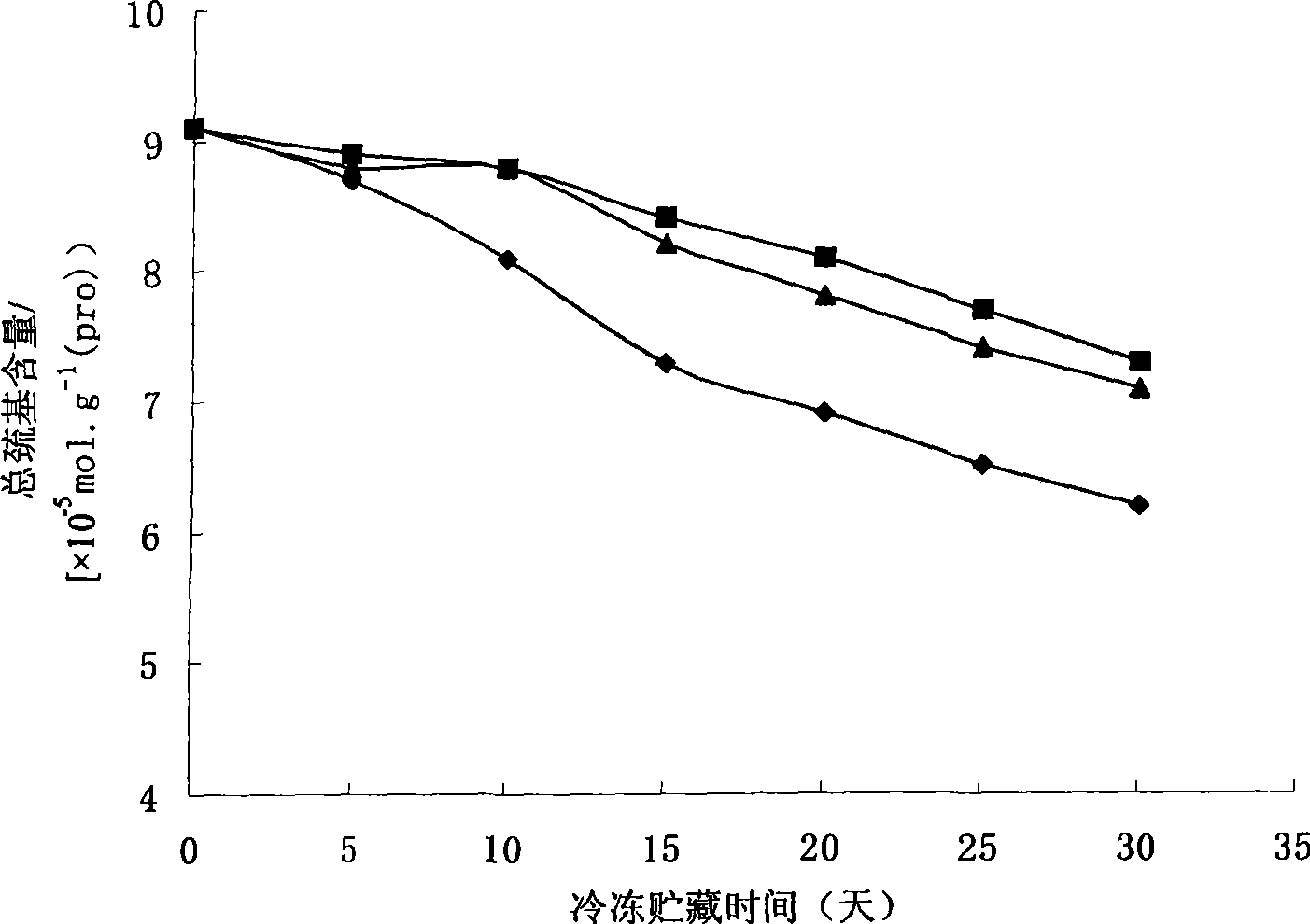

[0022] Embodiment 3, changes in total sulfhydryl and active sulfhydryl content of myofibrillar protein during frozen storage

[0023] Changes in the total sulfhydryl content of myofibrillar protein during frozen storage image 3 a. It can be seen from the figure that the total sulfhydryl content of each sample changed little after 5 days of frozen storage. During the subsequent frozen storage period, the total sulfhydryl content of the control group decreased significantly. -5 mol.g -1 (pro) reduced to 6.2×10 -5 mol.g -1 (pro), while the samples containing antifreeze did not decrease significantly, and the total sulfhydryl content of the frozen 30d konjac glucomannan and sucrose sorbitol samples were 7.1×10 -5 mol.g -1 (pro) and 7.3×10 -5 mol.g -1 (pro).

[0024]During frozen storage, the change trend of active thiol content of myofibrillar protein is similar to that of total sulfhydryl. For details, see Figure 4 . It can be seen from the figure that the control tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com