Poultry meat thawing method

A technology for poultry meat and frozen storage is applied in the field of thawing of livestock meat, which can solve the problems of complicated thawing process and decreased protein hydration force, and achieve the effects of avoiding juice outflow, reducing damage, and avoiding aggregation and denaturation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

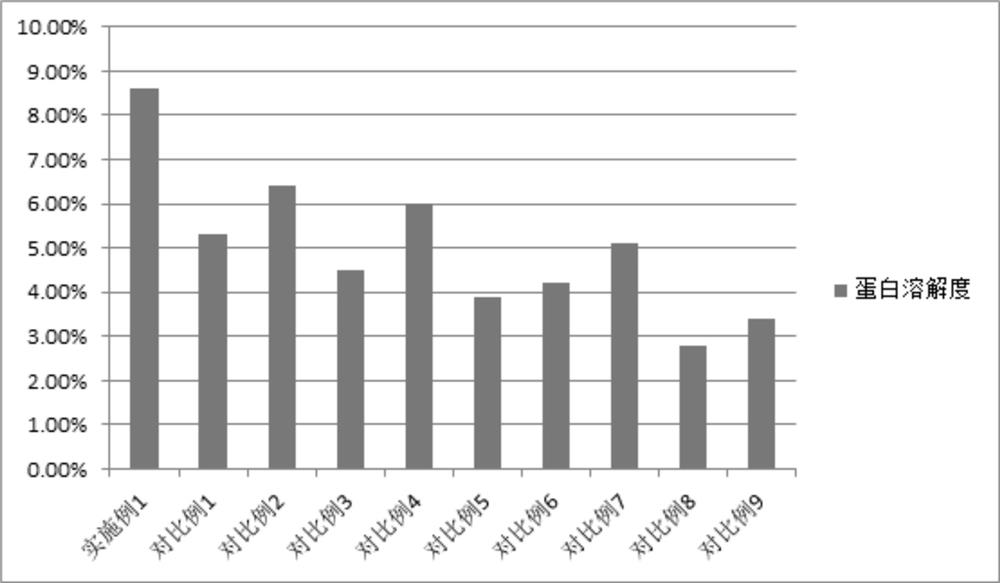

Examples

Embodiment 1

[0032] A kind of thawing method of livestock meat

[0033] (1) Preparation of soaking solution: Mix modified starch, macroalgae extract, cactus stem extract and sodium polyglutamate in a mass ratio of 4:0.6:1.5:0.02 to obtain a composite powder; Add 11 times warm water at 52°C for magnetic stirring for 12 hours to obtain the soaking solution for later use;

[0034] (2) Prepare pretreated rabbit meat: change the rabbit meat to a block of 3×3×3cm, add 3.5 times the amount of soaking solution and ultrasonically soak for 50 minutes, treat for 5 minutes, and rest for 1 minute, and cycle until the end of ultrasonic treatment. The ultrasonic frequency is 15kHz and the intensity is 20W / cm²;

[0035] (3) Frozen storage treatment: put the pretreated rabbit meat in an electrostatic field with an output voltage of 2000V, a current of 0.3mA, and a freezing temperature of -32°C for 7 days to obtain frozen rabbit meat;

[0036] (4) Low temperature vacuum storage: vacuum storage under low t...

Embodiment 2

[0039] A kind of thawing method of livestock meat

[0040] (1) Preparation of soaking solution: Mix modified starch, macroalgae extract, cactus stem extract and sodium polyglutamate in a mass ratio of 3.5:0.5:1.3:0.001 to obtain a composite powder; Add 7 times, 46 ℃ warm water and magnetically stir for 12 hours to obtain the soaking solution for later use;

[0041] (2) Prepare pretreated rabbit meat: cut the rabbit meat into a block of 3×3×3cm, add 3 times the amount of soaking solution and ultrasonically soak for 45 minutes, treat for 5 minutes, rest for 1 minute, and cycle until the end of the ultrasonic treatment. The ultrasonic frequency is 12kHz and the intensity is 19W / cm²;

[0042] (3) Frozen storage treatment: put the pretreated rabbit meat in an electrostatic field with an output voltage of 1800V, a current of 0.25mA, and a freezing temperature of -28°C for 6 days to obtain frozen rabbit meat;

[0043] (4) Low temperature vacuum storage: vacuum storage under low tem...

Embodiment 3

[0046] A kind of thawing method of livestock meat

[0047] (1) Preparation of soaking solution: Mix modified starch, macroalgae extract, cactus stem extract and sodium polyglutamate in a mass ratio of 4.5:0.8:1.7:0.004 to obtain a composite powder; Add 12 times, 54 ℃ warm water and magnetically stir for 12 hours to obtain the soaking solution for later use;

[0048] (2) Prepare pretreated rabbit meat: cut the rabbit meat into a block of 3×3×3cm, add 4 times the amount of soaking solution and ultrasonically soak for 55 minutes, treat for 5 minutes, rest for 1 minute, and cycle until the end of ultrasonic treatment. The ultrasonic frequency is 18kHz and the intensity is 21W / cm²;

[0049] (3) Frozen storage treatment: put the pretreated rabbit meat in an electrostatic field with an output voltage of 2200V, a current of 0.35mA, and a freezing temperature of -36°C for 8 days to obtain frozen rabbit meat;

[0050] (4) Low temperature vacuum storage: vacuum storage under low temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com