Forming device for laundry detergent encasement

A molding device and liquid packing technology, applied in the direction of packaging, transportation and packaging, single objects, etc., to achieve the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing:

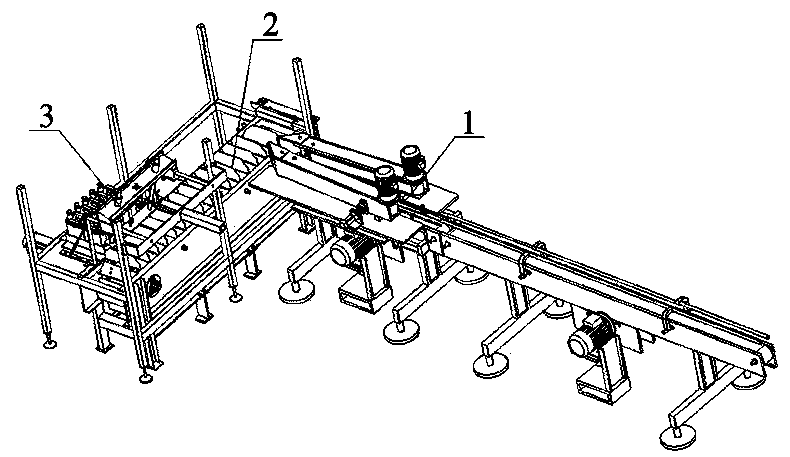

[0035] A molding device for packing laundry detergent provided by the present invention includes a collecting arm mechanism 1, a chain plate conveying mechanism 2, and a pushing mechanism 3; the collecting arm mechanism 1 is vertically docked with the front end of the chain plate conveying mechanism 2, and the pushing mechanism 3 Right above the chain conveyor mechanism 2.

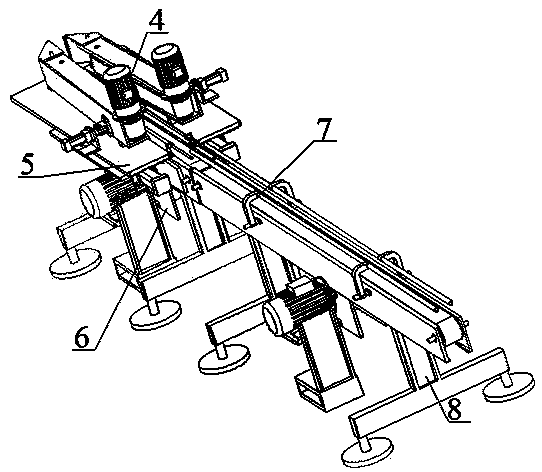

[0036] The collection arm mechanism 1 is composed of a collection arm 4, a collection arm moving device 5, a collection area conveying line 6, and a laundry liquid conveying line 7; the collecting arm 4 and the collecting arm moving device 5 are connected through a collecting arm support plate 17 The collection arm moving device 5 is connected to the collection area conveying line 6 through the fixed connection of the forwarding device support plate 33 and the collecting side plate 39; the collection ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com