Method for correcting beating degree of tobacco pulp in pulping process

A technology of pulping process and beating degree, applied in tobacco, tobacco preparation, application, etc., can solve the problems of unfixed sampling amount, large fluctuation of pulp quality, loss of fine fibers, etc., to improve product quality, improve qualification rate, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Take the tobacco raw material according to the raw material formula of the reconstituted tobacco leaf, and extract it with an aqueous solution in a constant temperature water bath for 30 minutes to obtain a tobacco slurry;

[0045] (2) Pulping by Vally beating method; the time is 5, 10, 15, 20, 30 min respectively, and 5 parts of pulping samples are obtained;

[0046] (3) adopt the assay method of GB / T 3332-2004 pulp beating degree and Schober's beating degree tester to measure beating degree DB (Schober-Rigler method) results are shown in Table 1;

[0047] (4) Use GB / T 2678.1-1993 pulp sieving test method to measure pulp fiber distribution, and get 48 mesh fine fiber proportion X ≥48mesh , the results are shown in Table 1;

[0048] Table 1 Determination of beating degree DB by national standard method

[0049]

[0050]

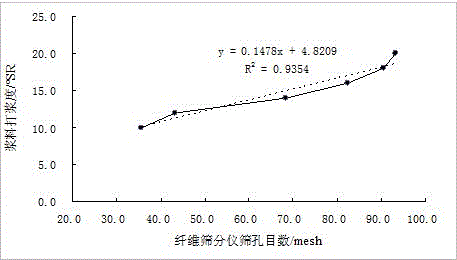

[0051] (5) According to Table 1, make tobacco pulp beating degree and pass through 48 order fine fibers proportion X ≥48mesh The working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com