Multi-volume-weight magnesium oxysulfate foam insulation board as well as production equipment and process thereof

A foamed insulation board and production equipment technology, applied in the field of cement, can solve problems such as the inability to meet the production of insulation products, and achieve the effects of seamless connection of automatic production, high reliability, and reduction of post labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

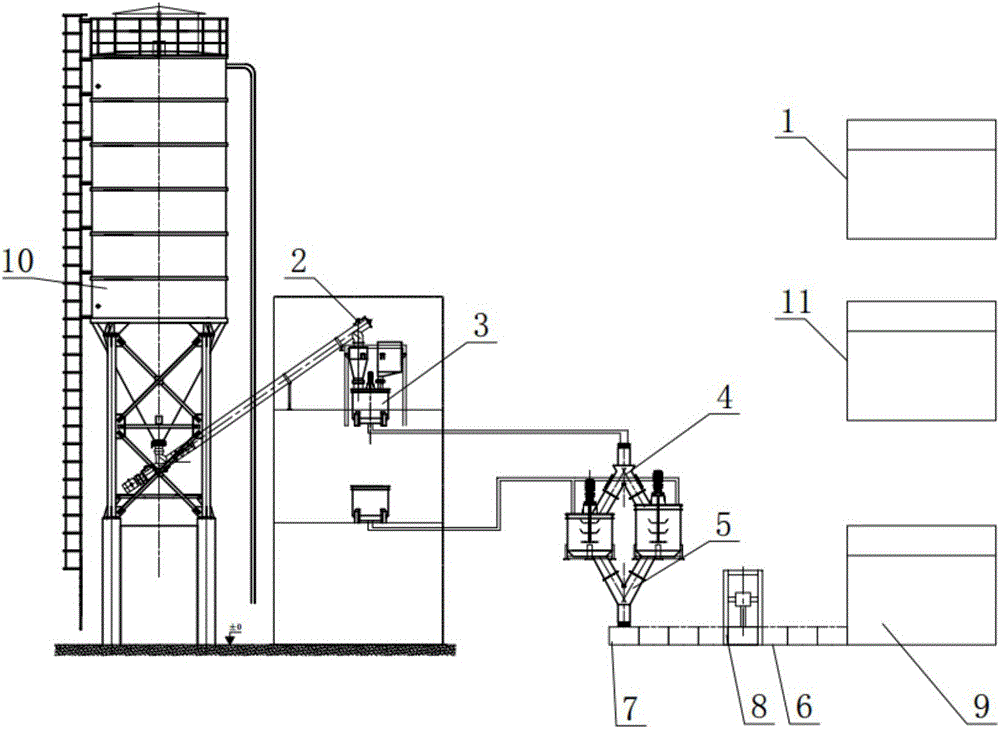

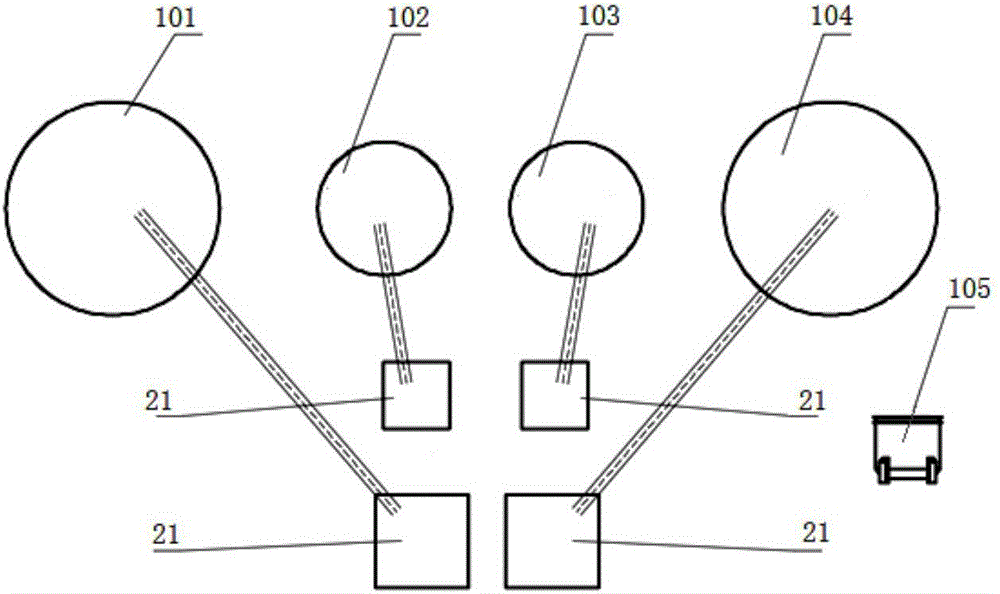

[0099] Using the present invention figure 1 The equipment shown is used for the preparation of four kinds of magnesium oxysulfide foamed insulation boards, and the ingredients are shown in Table 3. The following is the ratio of raw materials for the production of foam insulation boards, and the foam mixing tank used is 1.

[0100] table 3:

[0101] Material name

Foam mixing tank 1

Foam mixing tank 2

Foam mixing tank 3

Foam mixing tank 4

magnesium sulfate

1500

1500

1500

1500

magnesium oxide

2700

2700

2700

2700

Admixture

300

300

300

300

1800

1800

1800

1800

water

2300

2250

2200

2150

250

300

350

400

[0102] The admixture is a mixture of various admixtures, which are not listed here.

[0103] The preparation method is:

[0104] 1. Obtain the relationship curve of water, magnesium sul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com