Spiral plate type vinyl chloride synthetic converter

A spiral plate type, vinyl chloride technology, applied in chemical instruments and methods, organic chemistry, hydrogen halide addition preparation, etc., can solve problems such as leakage, reduce hot water scale, improve production technology level, and avoid corrosion leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

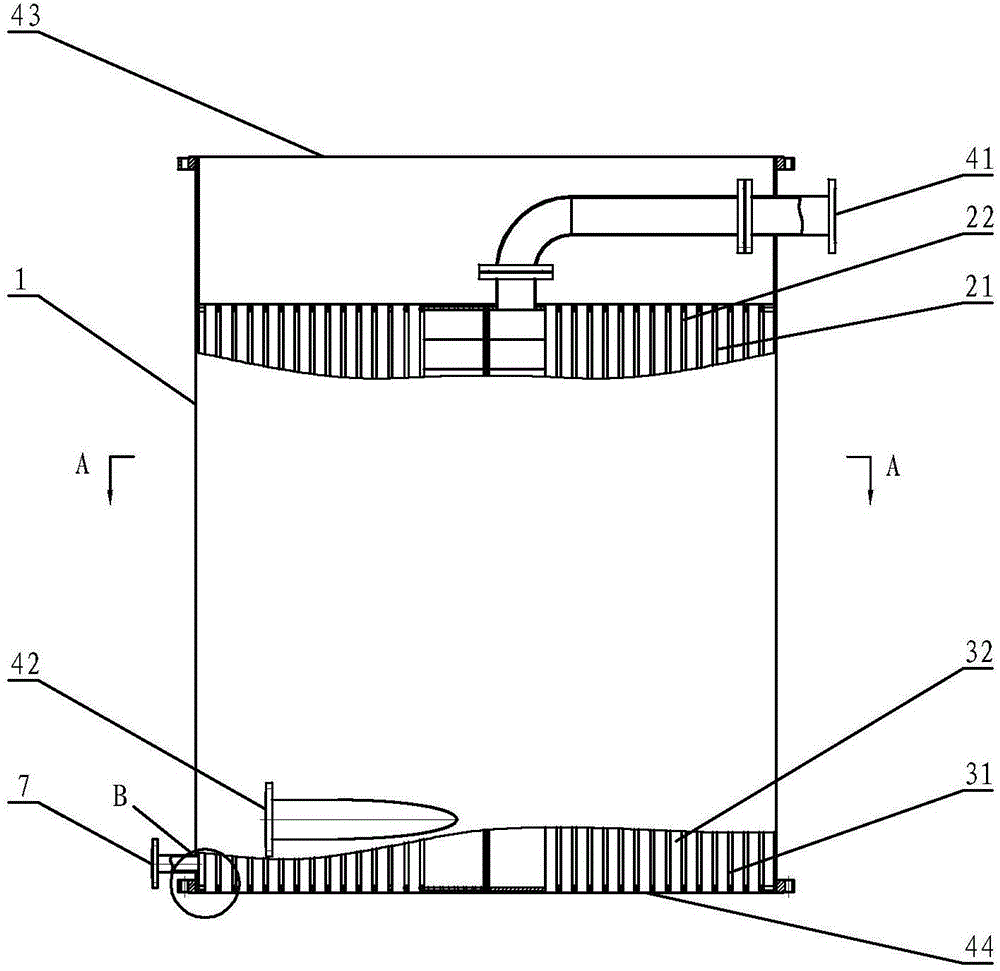

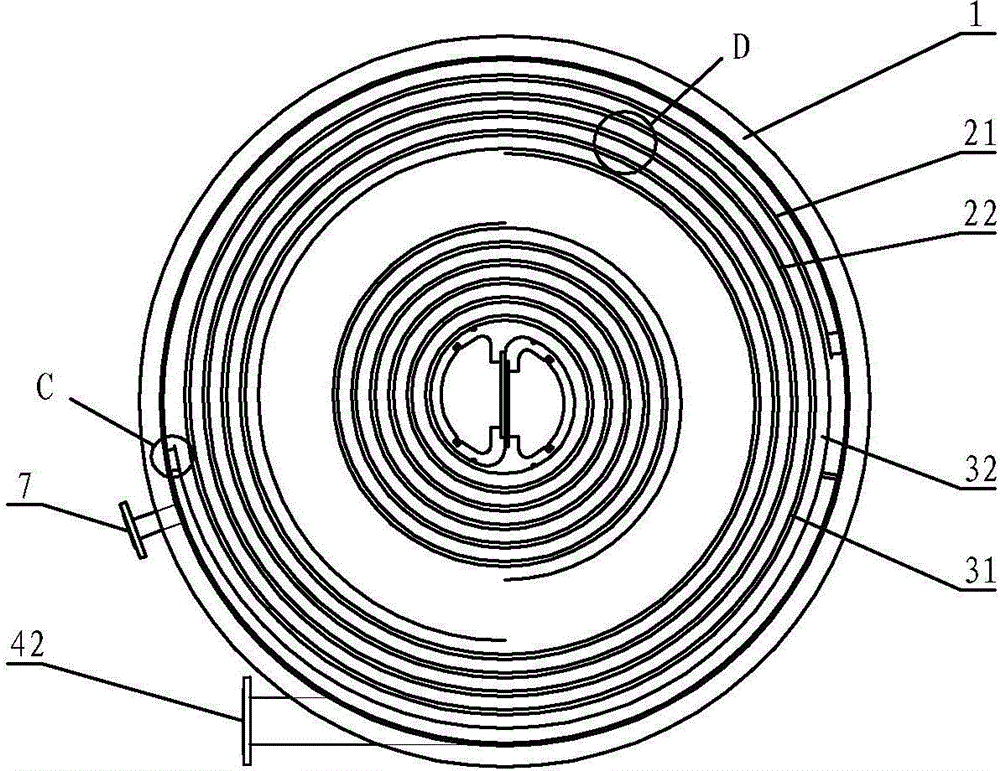

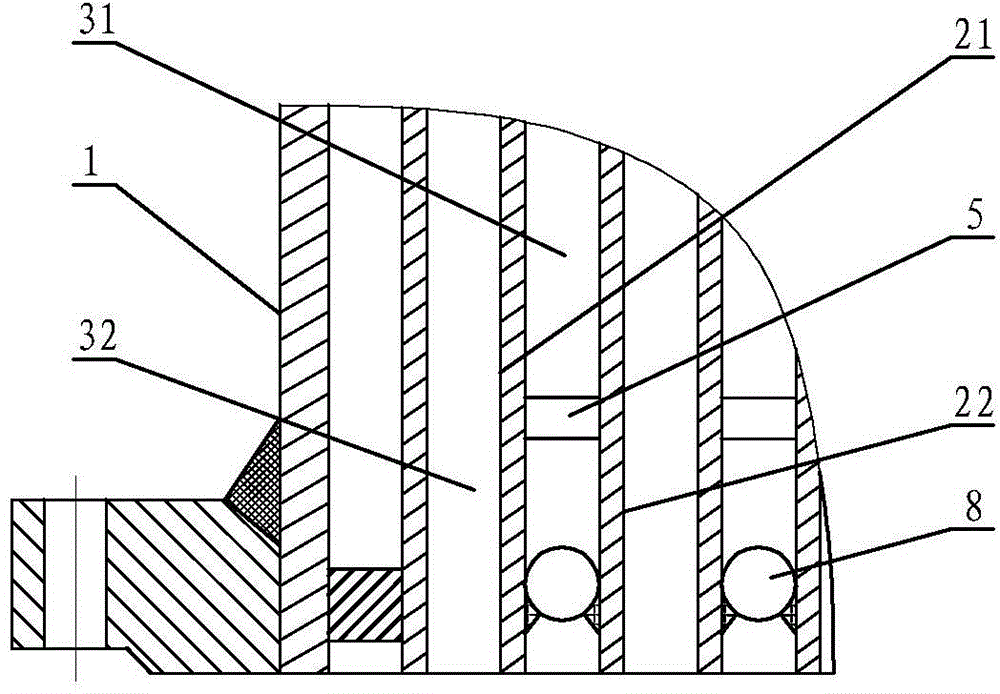

[0020] Embodiment one: see attached Figure 1-5 As shown, the spiral plate type vinyl chloride synthesis converter includes a vertical cylindrical casing 1 with both ends open, a first heat exchange plate 21 and a second heat exchange plate 21 arranged in the casing 1 in a double helical shape. The heat plate 22, the first channel 31 and the second channel 32 arranged in a double helix are formed between the first heat exchange plate 21 and the second heat exchange plate 22, and the upper and lower sides of the first channel 31 are closed. In this embodiment, the Round steel 8 is welded and plugged, the center of its spiral has a first opening 41, and the edge of its spiral has a second opening 42; the spiral center of the second channel 32 and the spiral edge are closed, and its upper and lower sides are open to form the third opening 43 and The fourth opening 44 is provided with a catalyst on the side wall of the second channel. The first opening 41 is the cooling liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com