Device and method for continuous production of spherical sodium benzoate

A sodium benzoate and spherical technology is applied in the field of devices for continuous production of spherical sodium benzoate, which can solve the problems of waste of resources and low production efficiency, and achieve the effects of increasing production capacity, saving resources and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

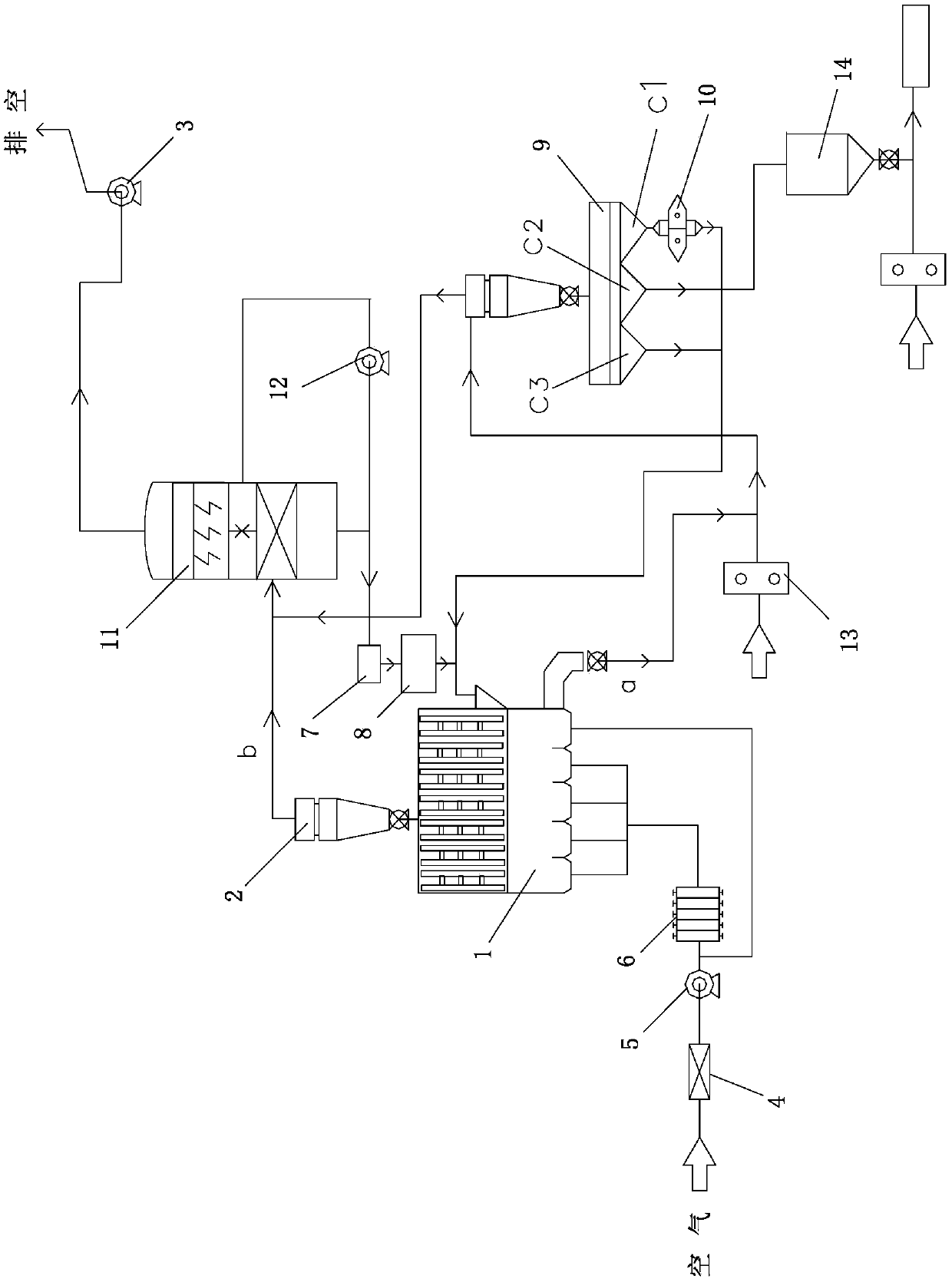

[0030] A kind of device of continuous production spherical sodium benzoate, this device comprises air pretreatment system, raw material system, granulation system and screening system, wherein: described granulation system comprises granulation tower 1 and with described granulation tower 1 upper end The connected cyclone separator 2, and the induced draft fan 3 connected with the top of the cyclone separator 2; the granulation system is connected with the air pretreatment system, and the air pretreatment system includes a coarse filter connected in sequence 4. The blower 5 and the air heater 6; the outlet end of the air heater 6 communicates with the air inlet at the bottom of the prilling tower 1; the feed port of the prilling tower 1 is connected to the raw material system, and the raw material system Comprising a slurry pool 7 and an atomizer 8, the outlet of the atomizer 8 is connected with the feed inlet of the prilling tower 1; the discharge port of the prilling tower 1 ...

Embodiment 2

[0042] Utilize the device granulation method of continuous production spherical sodium benzoate described in embodiment 1 as follows:

[0043] Before the new drive, spread 1-2 tons of spherical sodium benzoate finished product on the granulation tower as granulation seeds in advance, and then operate according to the following steps:

[0044] 1) adding mass concentration in the slurry tank is 42% sodium benzoate slurry;

[0045] 2) Start the induced draft fan, blower and air heater. After the air is purified by the coarse filter, it is sent to the air heater for heating by the blower, and then sent to the prilling tower for upward blowing; the pressure of the blower is 15KPa, and the temperature of the air heater is 180 ~200℃;

[0046] 3) Start the atomizer, the atomization pressure is 1.2MPa, and the sodium benzoate slurry in the slurry tank is transported to the prilling tower, and atomized and sprayed to form spherical sodium benzoate particles;

[0047] 4) After atomizin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com