Multi-volume-weight foaming panel and production device and technology thereof

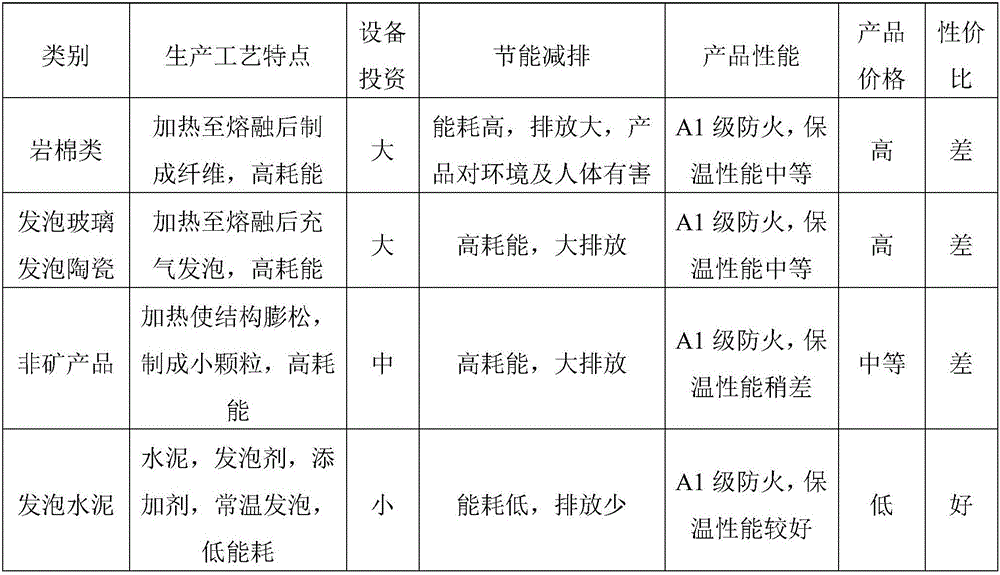

A technology for production equipment and foamed boards, applied in the field of cement, can solve the problems that the degree of foaming of foamed cement cannot be guaranteed, the production of thermal insulation products cannot be satisfied, and the accuracy of adding metering is not high, so as to achieve seamless connection and automatic production and improve production Technological level, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

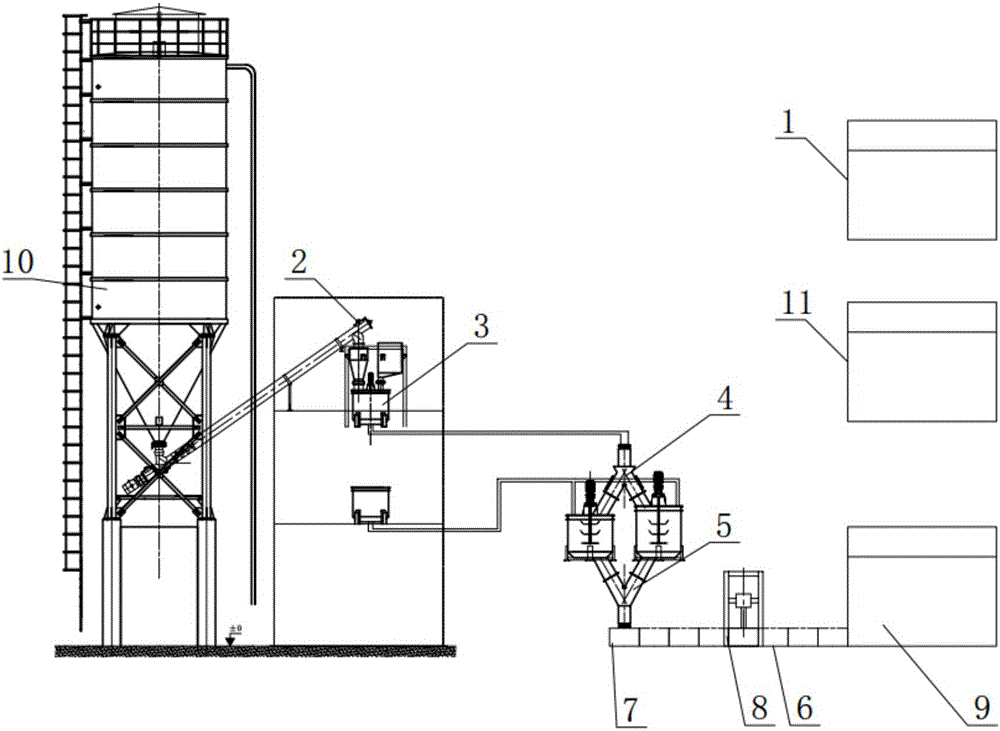

[0085] Using the present invention figure 1 The equipment shown is used for the preparation of four kinds of magnesium oxysulfide foamed boards, and the ingredients are shown in Table 3. The following is the ratio of raw materials for the production of foam insulation boards, and the foam mixing tank used is 1.

[0086] table 3:

[0087]

[0088] The admixture is a mixture of various admixtures, which are not listed here.

[0089] The preparation method is:

[0090] 1. Obtain the relationship curve between the raw material and the bulk density through the pre-test, input the data of the relationship curve into the control system 1, and the control system controls the batching system 2 to batch the raw materials described in Table 3;

[0091] 2. The raw material is transported from the material storage system 10 to the mixing system 3 through the batching system 2 for mixing, and the prepared mud with different volumes is placed in different foaming mixing tanks;

[0092...

Embodiment 2

[0098] Using the present invention figure 1 For the equipment shown, 42.5 grade ordinary Portland cement is used as the cementitious material to prepare foam insulation boards, and the ingredients are shown in Table 5.

[0099] table 5:

[0100]

[0101]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com