Charging system for the granulating preparation of sodium benzoate particle and operation process thereof

A technology of sodium benzoate and production process, which is applied in the field of feeding system and operation process, can solve the problems of low product quality stability, increased impurities entering the prilling tower, and poor operating environment for workers, so as to improve the production technology level and improve Production workshop environment, the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

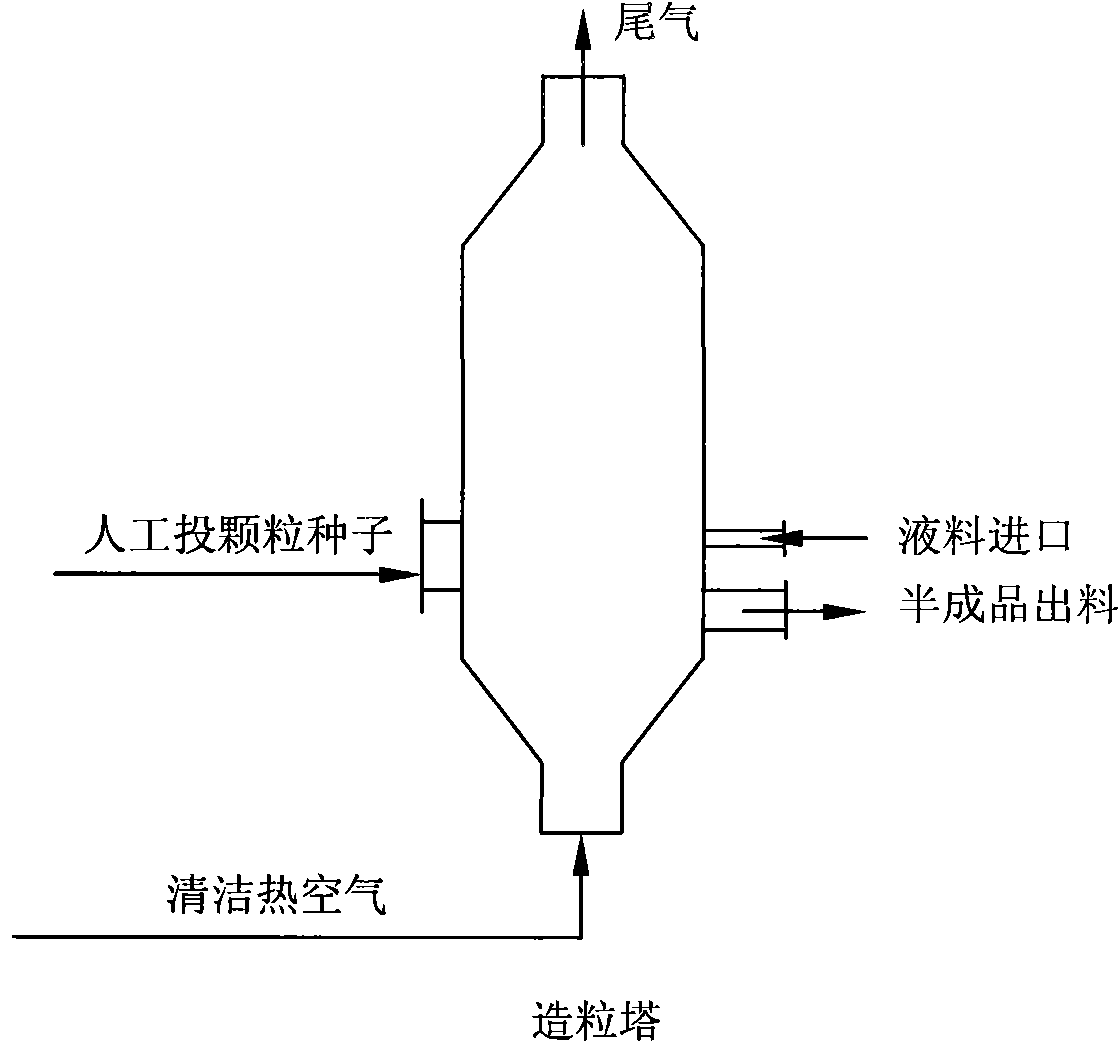

Problems solved by technology

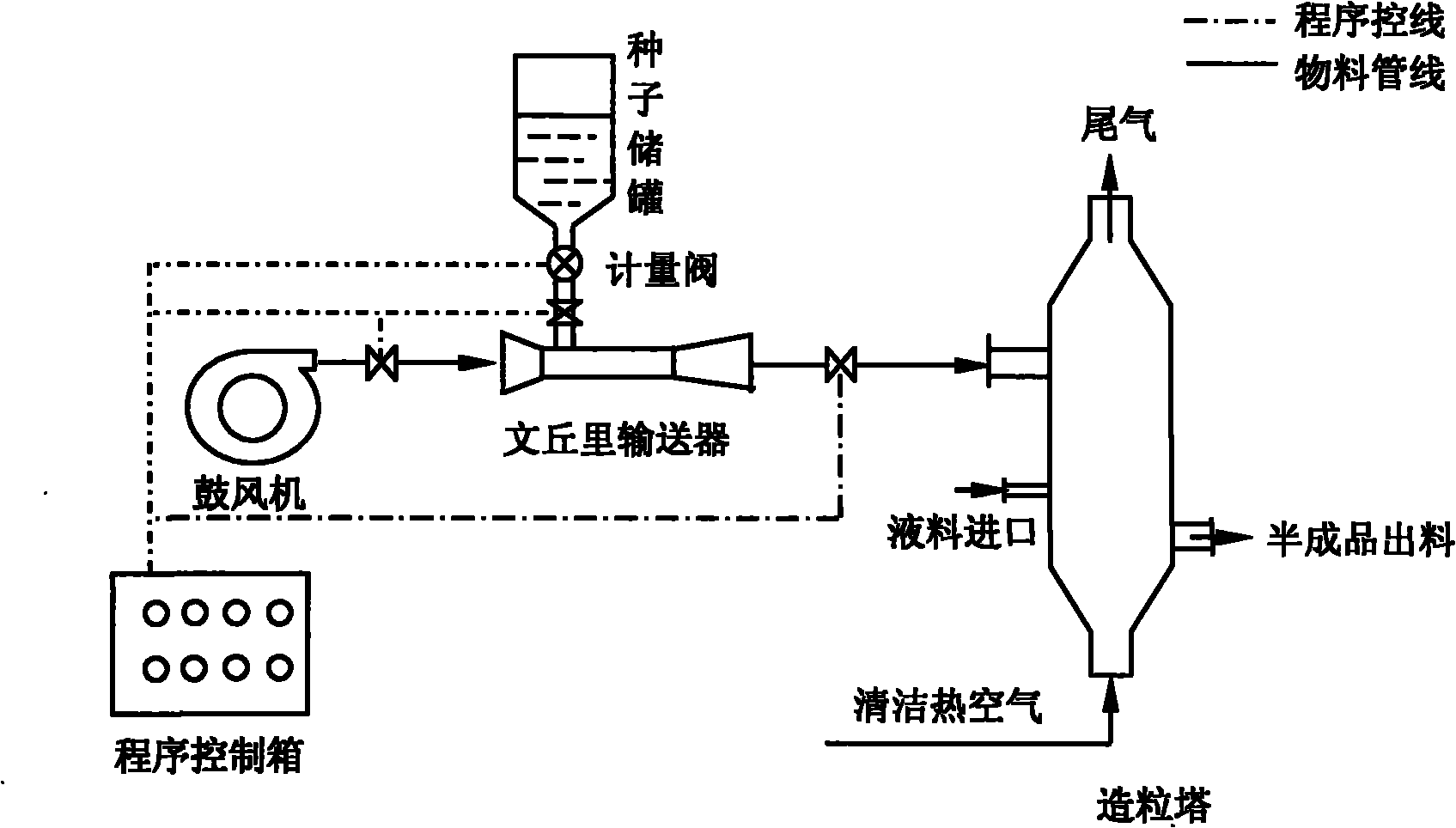

Method used

Image

Examples

Embodiment 1

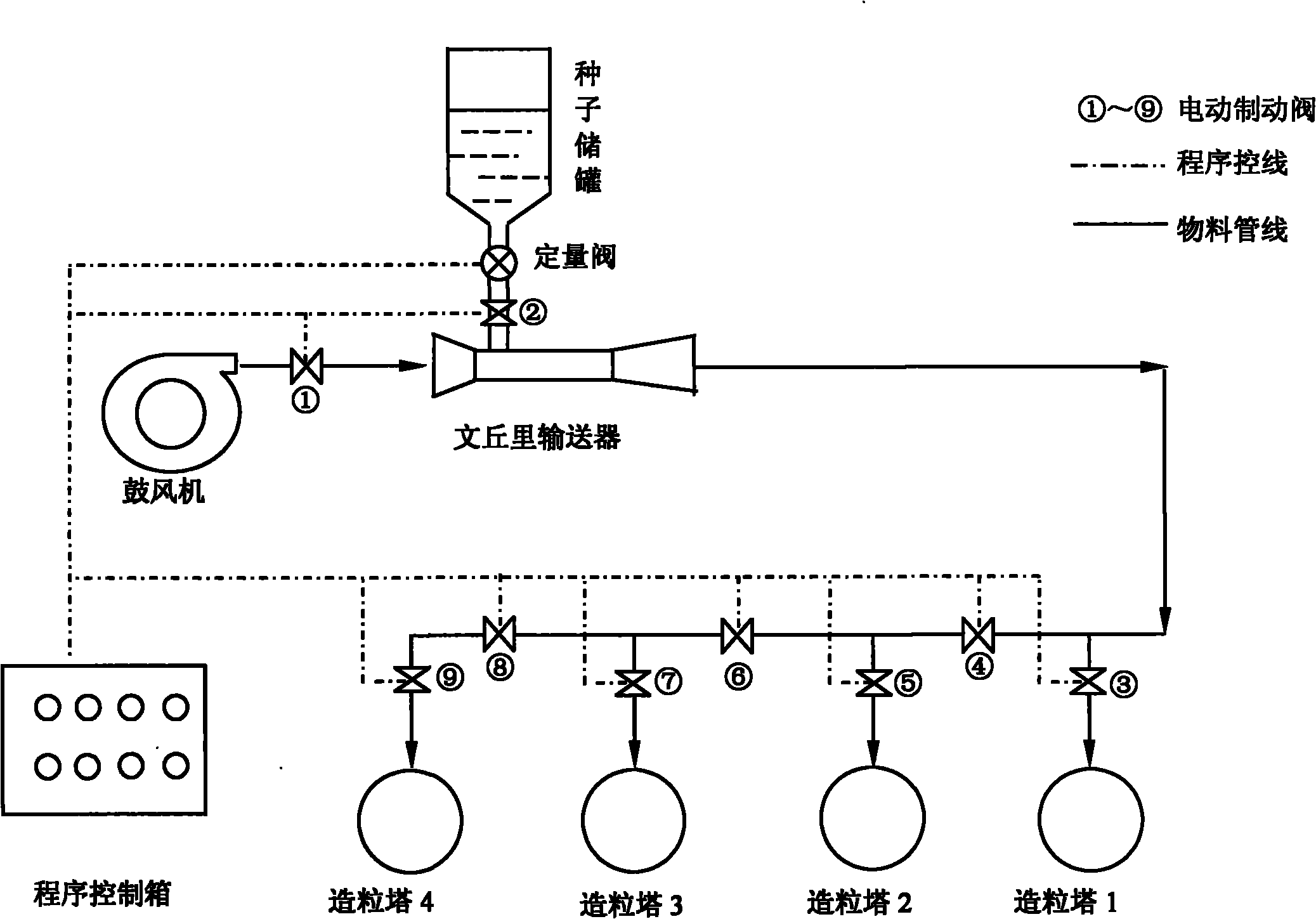

[0019] Example 1: The electric program control box is used to set the program, and the electric control box is connected to each electric brake valve through the signal line. Firstly, the blower and the brake valve of the material inlet of the first prilling tower are opened, and the blower is used to blast the pipeline , so that the pipeline for conveying seeds is unblocked; after 5 to 10 seconds, the program automatically opens the seed brake valve, and the granulated seeds flow down from the seed storage tank to the Venturi conveying pipe; the granular seeds are in contact with high-speed air in the Venturi conveyer Mix evenly, and then enter the prilling tower under the wind force; when the number of seeds reaches the set value, the metering valve will feed back to the program control box and close the seed brake valve; continue to ventilate for 10-15 seconds to blow out the seeds in the pipeline, The program closes the brake valve of the blower and the brake valve of the p...

Embodiment 2

[0020] Embodiment 2: Use the electric program control box to set the program, the electric control box is connected with each electric brake valve through the signal line, firstly open the blower, the main pipe and the brake valve of the material inlet of the second prilling tower, and use the blower to blow air Purge the pipeline to make the pipeline for conveying seeds unblocked; after 10 to 20 seconds, the program automatically opens the seed brake valve, and the granulated seeds flow down from the seed storage tank to the Venturi conveying pipe; The high-speed air contacts and mixes evenly, and then enters the prilling tower under the force of the wind; when the number of seeds reaches the set value, the metering valve feeds back to the program control box and closes the seed brake valve; continue to ventilate for 15-25s to blow the seeds in the pipeline After cleaning, the program closes the blower, the main pipeline and the brake valve of the material inlet of the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com