Fluorination technology for recovering fluorine gas

A kind of chemical process, fluorine gas technology, applied in the field of uranium conversion, can solve the problems of small demand for UF6 and unobvious recycling economy, achieve significant economic and environmental benefits, loose technical conditions, avoid wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

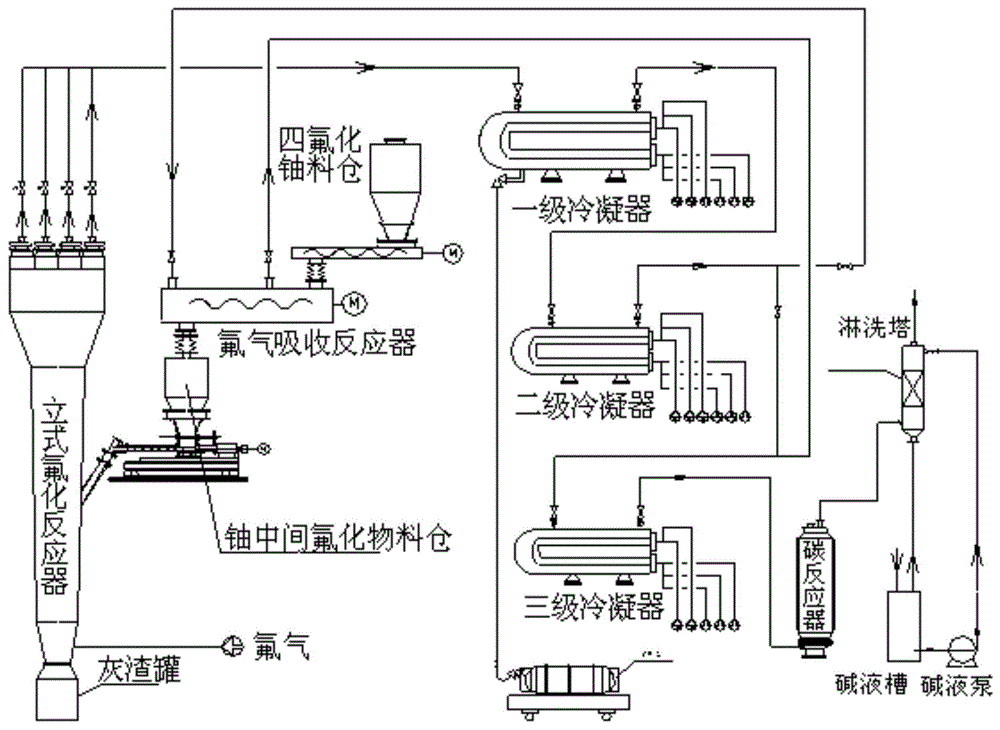

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0016] The invention mainly consists of two parts: a fluorination process and a fluorine gas recovery and reuse process. The fluorination reactor is a vertical fluorination reactor, and the fluorine gas absorption reactor is a horizontal stirred bed reactor. The fluorine gas absorption reactor is docked with the fluorination reactor, and the solid material feed end of the absorption reactor is directly used as the system material inlet end, and the solid material inlet end of the fluorination reactor is replaced by the material outlet end of the fluorine gas absorption reactor, omitting material transfer Compared with foreign fluorination process technology routes, the process flow of this method is shorter. The gas inlet port of the fluorine gas absorption reactor is the furnace gas containing fluorine gas and a small amount of uncondensed deposited UF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com