Automatic power regulation device for polysilicon reducing furnace

A reduction furnace and polysilicon technology, which is applied in the field of automatic power adjustment devices for polysilicon reduction furnaces, can solve problems such as harmonic noise, and achieve the effects of reducing noise pollution, short current interruption time, and guaranteed production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

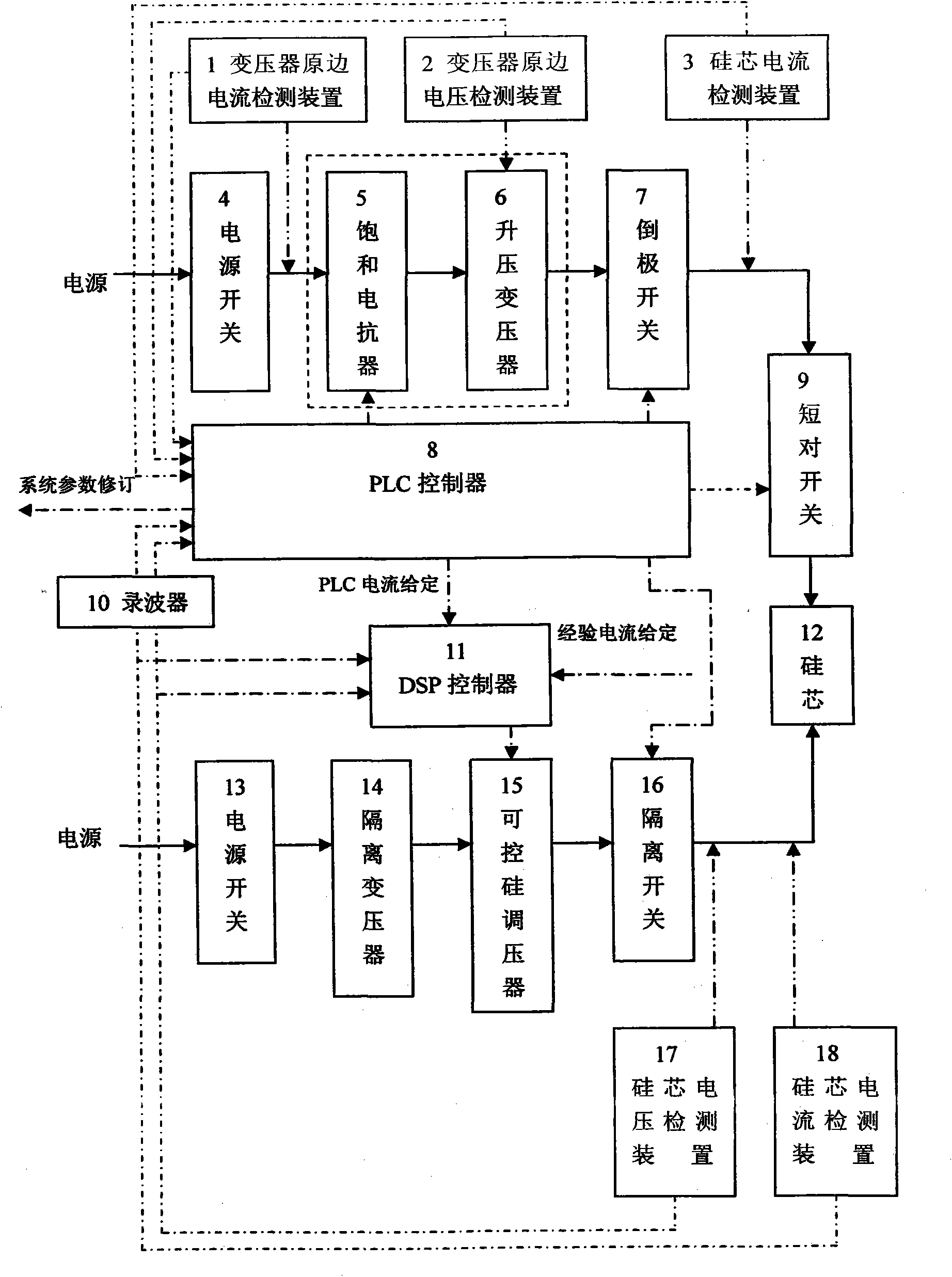

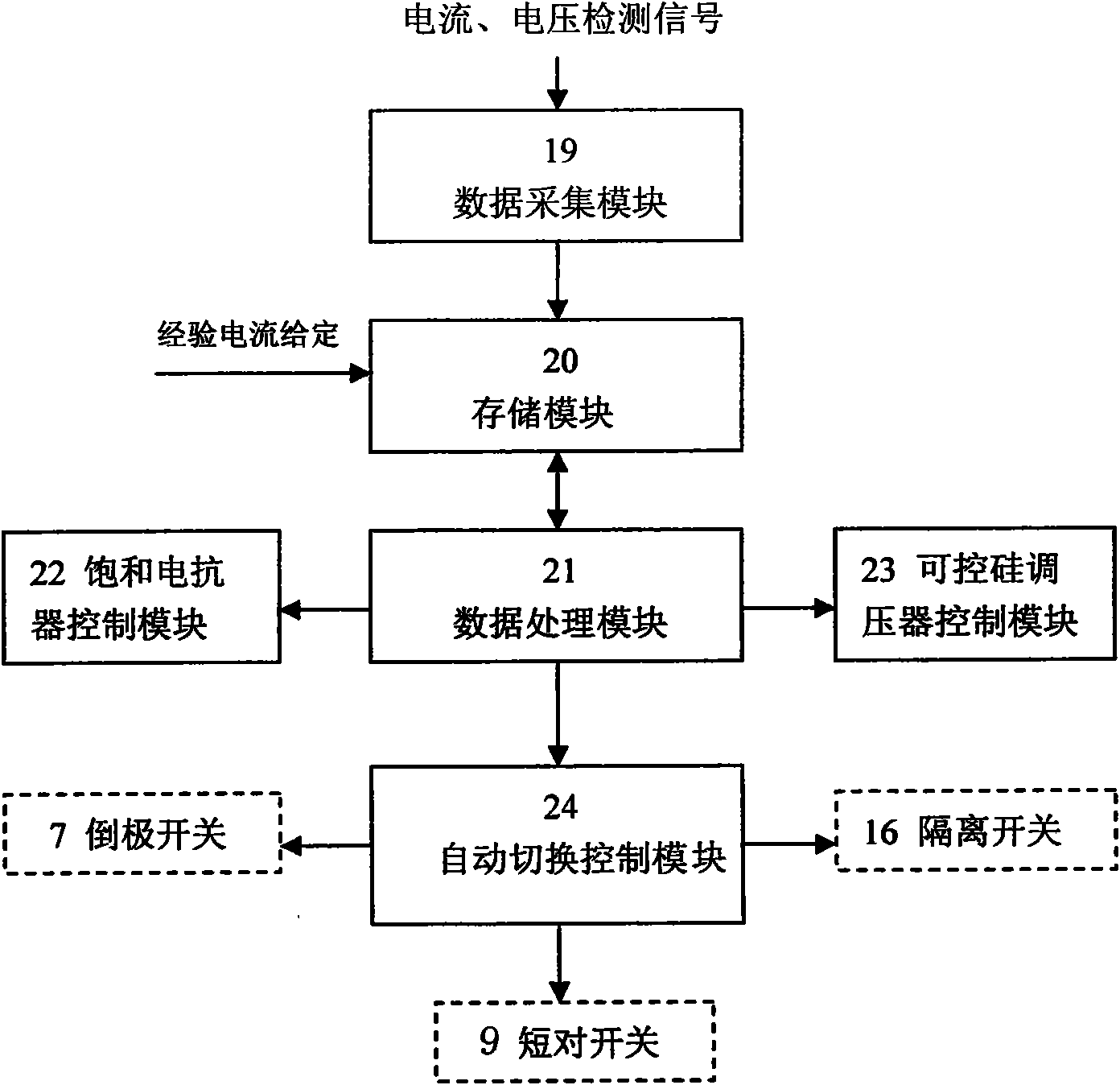

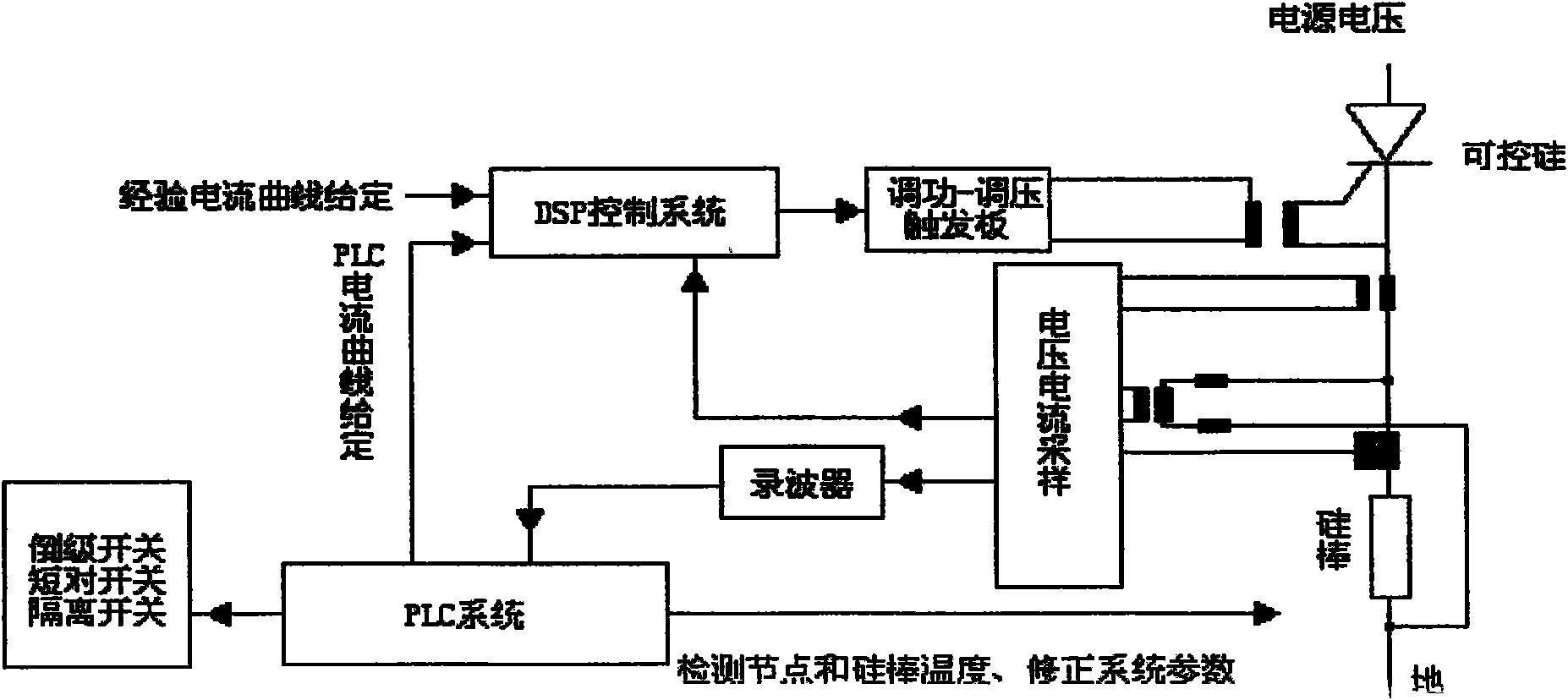

[0039] see Figure 1 to Figure 4 : This polysilicon reduction furnace automatic power adjustment device comprises a silicon core preheating device, a silicon core constant temperature heating device and their controllers, and the silicon core preheating device has a sequentially connected power switch 4, a saturated reactor 5, a booster Transformer 6, pole reversal switch 7, the silicon core preheating device is connected to the silicon core 12 through its pole reversal switch 7; the silicon core constant temperature heating device has a power switch 13, an isolation transformer 14, a thyristor voltage regulator 15 connected in sequence , Isolation switch 16, the silicon core constant temperature heating device is connected to the silicon core 12 through its isolation switch 16.

[0040]The controller is composed of a signal detection device and a central processing unit. The signal detection device includes a transformer primary side current detection device 1 of a preheating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com