An automatic hooking system for lifting vehicles on large ships

A ship and automatic technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve problems such as easy to swing, achieve the effect of improving work efficiency, improving the ability to guarantee operations, and high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

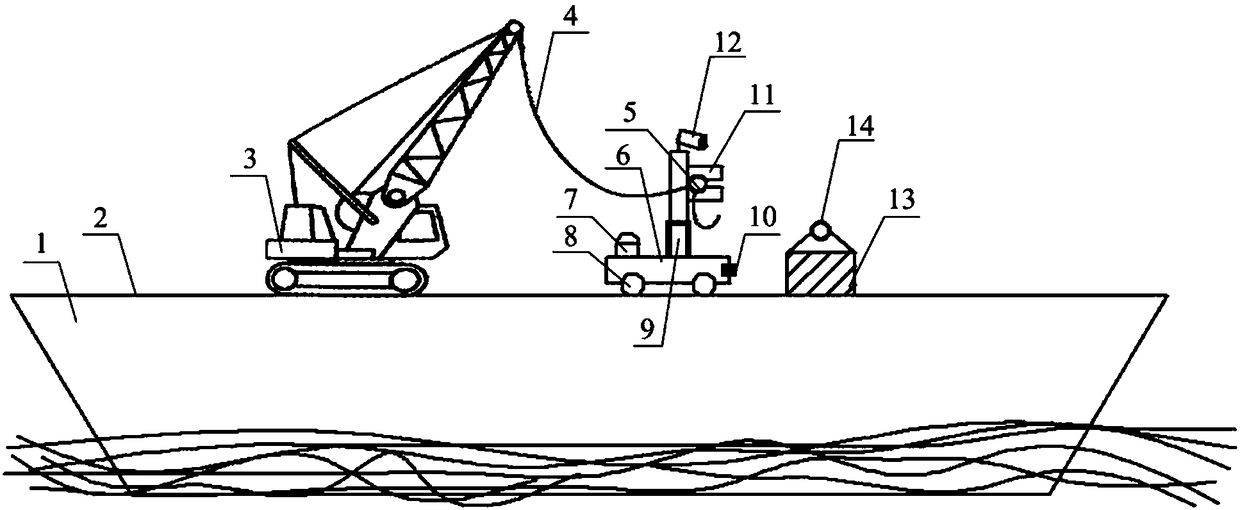

[0022] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in further detail:

[0023] As shown in the accompanying drawings, an automatic hooking system for lifting vehicles on a large ship of the present invention includes the following components: a ship 1, a deck 2, a lifting vehicle 3, a steel cable 4, a hook 5, a carrying platform 6, Electronic control system 7, wheels 8, lifting device 9, ultrasonic sensor 10, mechanical arm 11, camera 12, weight 13 and suspension ring 14.

[0024] The relationship between them is: lifting vehicle 3, steel cable 4, hook 5, carrying platform 6, electric control system 7, wheels 8, lifting device 9, ultrasonic sensor 10, mechanical arm 11, camera 12, heavy objects 13 and lifting ring 14 are located on the deck 2 of the ship 1; the hook 5 is connected with the lifting vehicle 3 through the steel cable 4; The upper part of the platform 6; the ultrasonic sensor 10 is located at the front of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com