Steel rolling production process used in steel production

A production process and steel technology, applied in the field of process flow, can solve the problems of high investment in equipment and infrastructure, inability to achieve energy saving and environmental protection, complex process, etc., and achieve the effects of less production investment, improved equipment utilization, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

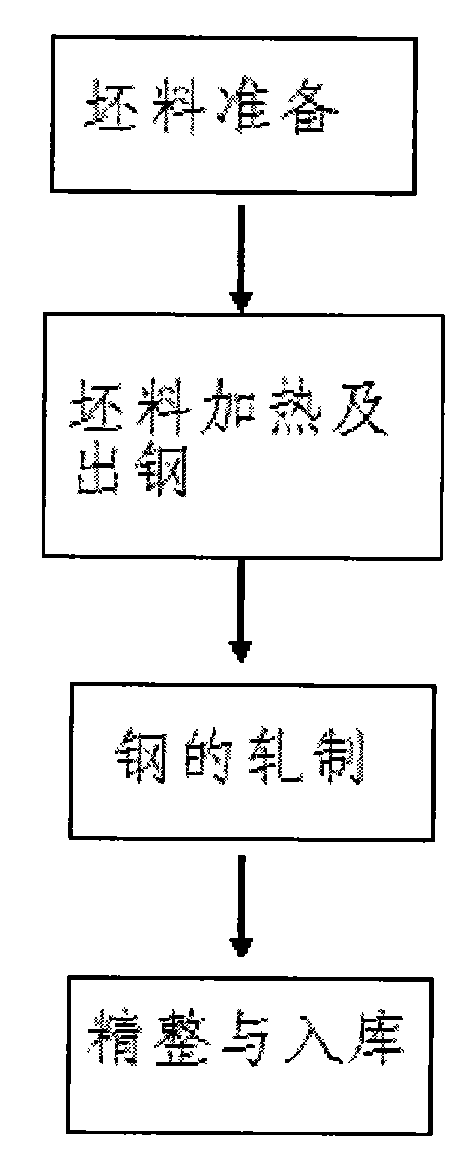

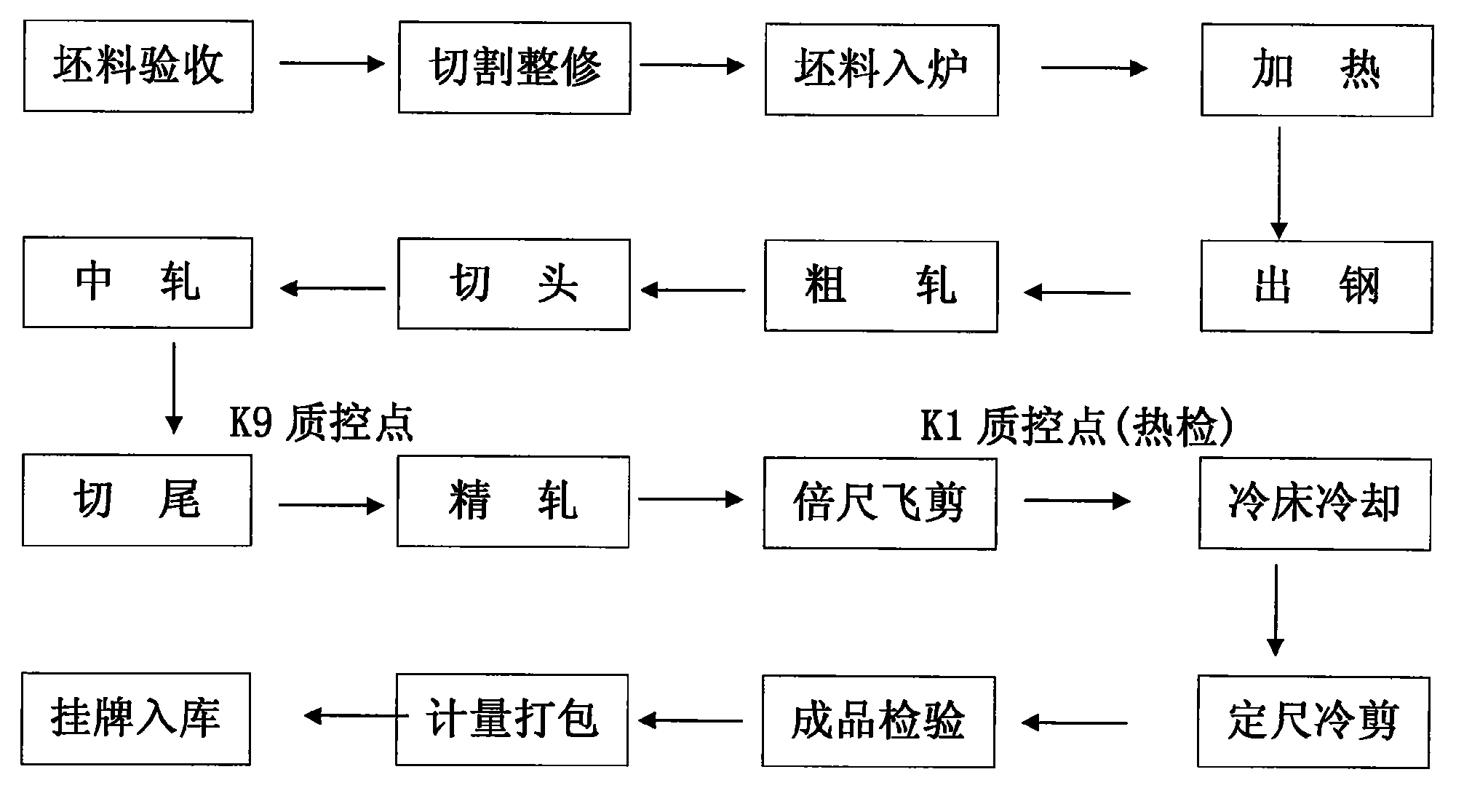

[0037] see figure 1 , the present invention is a steel rolling production process applied in steel production, the rolling steel produced by extruding metal between rolls to make it plastically deformed, its technological process is: billet preparation, billet heating and tapping, steel rolling, Finishing and warehousing; in the present invention, the purpose of billet heating is to improve plasticity and reduce deformation resistance, so as to facilitate rolling. In the rolling of steel, the steel billet is rolled by a two-roll mill, which adopts a continuous configuration, and its productivity and quality are superior to other methods. Among them, the type of rolled steel is HRB335 among the hot-rolled ribbed steel bars for reinforced concrete, with specifications ranging from Φ10mm to Φ25mm. It is the most common construction steel in China at present. Steel conforming to GB1499.2-2007. In this embodiment, the longitudinal hot rolling adopted for steel rolling, that is, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com