Novel transmission shaft with constant-speed ball cage structure

A constant velocity spherical cage and drive shaft technology, applied in the field of drive shafts, can solve problems such as insufficient performance and stability, easy failures, and many parts, and achieve the requirements of compactness and light weight, improve overall life, and reduce product types.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. While the invention will be described in conjunction with the preferred embodiments, it will be understood that it is not intended to limit the invention to the described embodiments. On the contrary, the invention is to cover alternatives, modifications and equivalents, which may be included within the scope of the invention as defined by the appended claims.

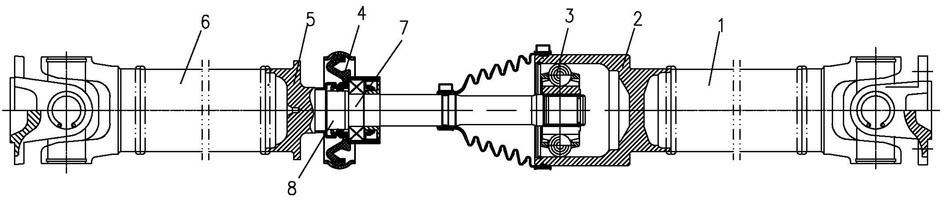

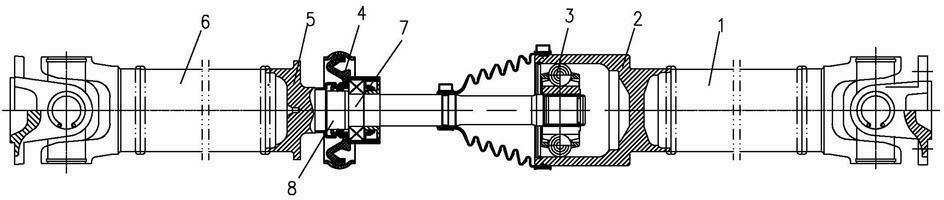

[0011] see figure 1 As shown, this new drive shaft with constant velocity ball cage structure includes front axle tube 1, cylindrical shell 2, ball cage 3, and rear axle tube 6 in sequence. The front axle tube 1 is directly welded to the cylindrical shell 2, and the cylindrical shell The other end of the shaped shell 2 is provided with a ball cage 3, and the front axle tube 1 is connected with the shaft head 5 of the ball cage 3, and the shaft head 5 is provided with an intermediate bracket 4. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com