Rearview mirror rod

A technology for rearview mirrors and rods, which is applied in the field of rearview mirror product structure, can solve the problems of increased production process difficulty and the difficulty of placing the first ring on the rearview mirror rod, so as to reduce product types, reduce development costs, The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

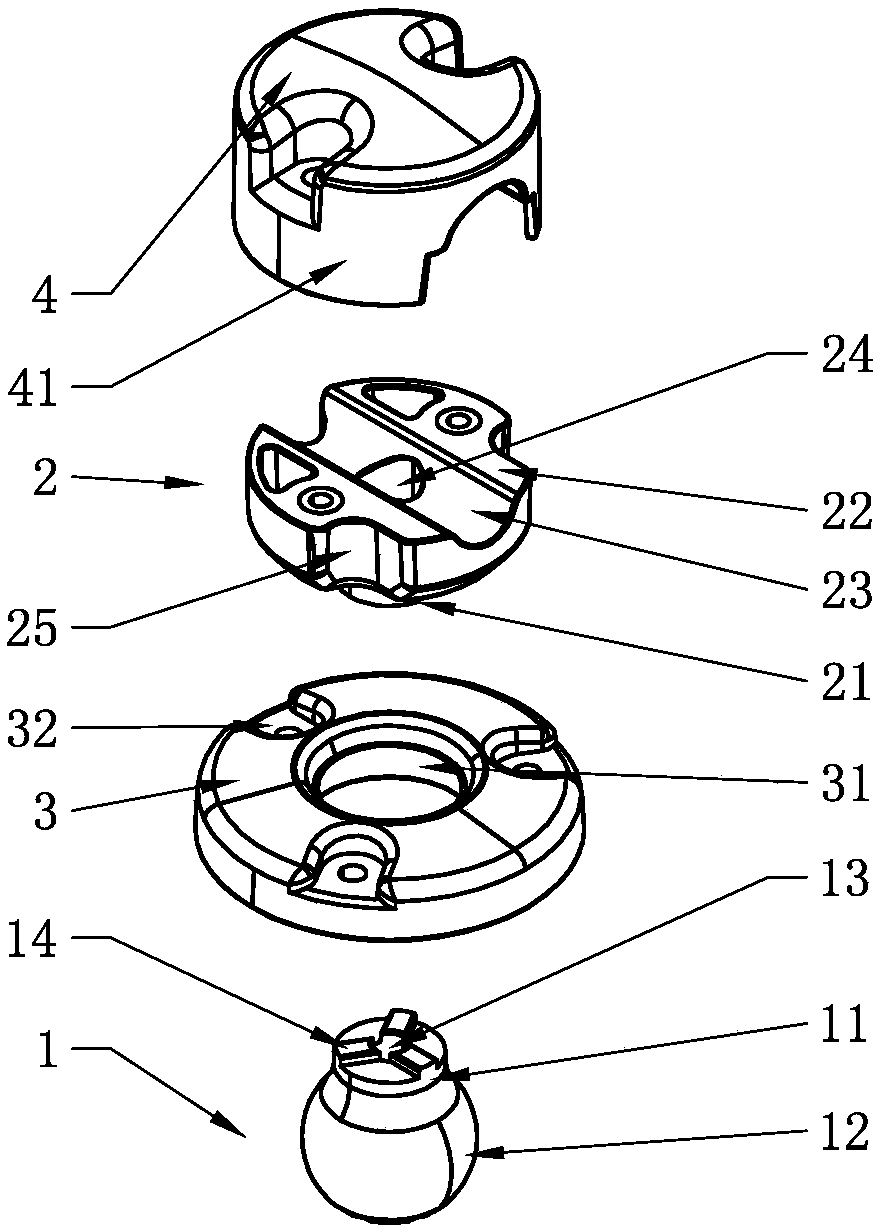

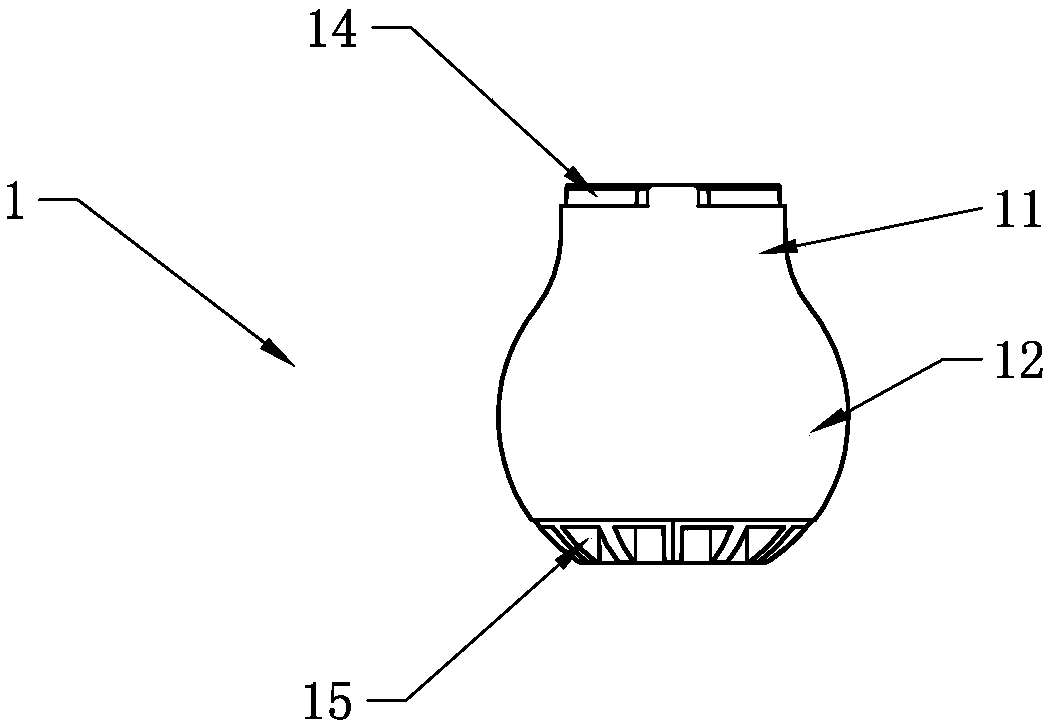

[0034] Embodiment 1: The end of the first rod 11 facing away from the first sphere 12 is provided with an external thread, and the second rod 21 is correspondingly provided with a threaded hole. External threads and threaded holes are common structures, which are not shown in the figure.

Embodiment 2

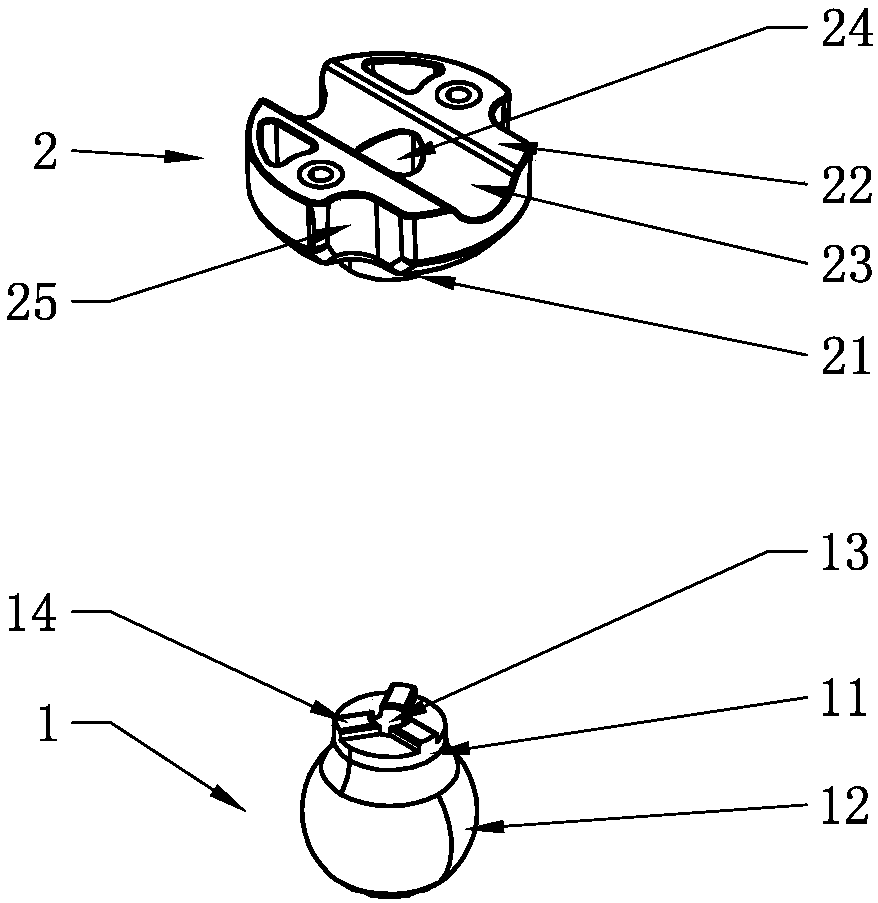

[0035] Embodiment 2: The end surface of the second rod part 21 is provided with a second through hole 24 , the second through hole 24 accommodates a second bolt, and the screw part of the second bolt is connected with the first rod part 11 .

[0036] Using the second bolt to connect the first half rod 1 and the second half rod 2 can enhance the connection strength and reduce the risk of breaking the rearview mirror rod.

[0037] As a further extension of the second embodiment, the end surface of the first rod part 11 is provided with a first protrusion 14, the first protrusion 14 is provided along the edge of the end face of the first rod part 11, and the end surface of the second rod part 21 is provided with a container Set the second recess of the first protrusion 14.

[0038] The cooperation between the first protrusion 14 and the second concave part prevents the first rod part 11 from rotating relative to the second rod part 21 , avoids loose connection, and avoids acciden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com