Improved copper electroplating method of crystal silicon solar battery

A technology of solar cells and copper electroplating, applied in circuits, electrical components, climate sustainability, etc., can solve the problems of reducing the lifetime of minority carriers, prone to amorphous impurities, and reducing electrical conductivity, etc., to improve the manufacturing process Level, the effect of ensuring battery performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

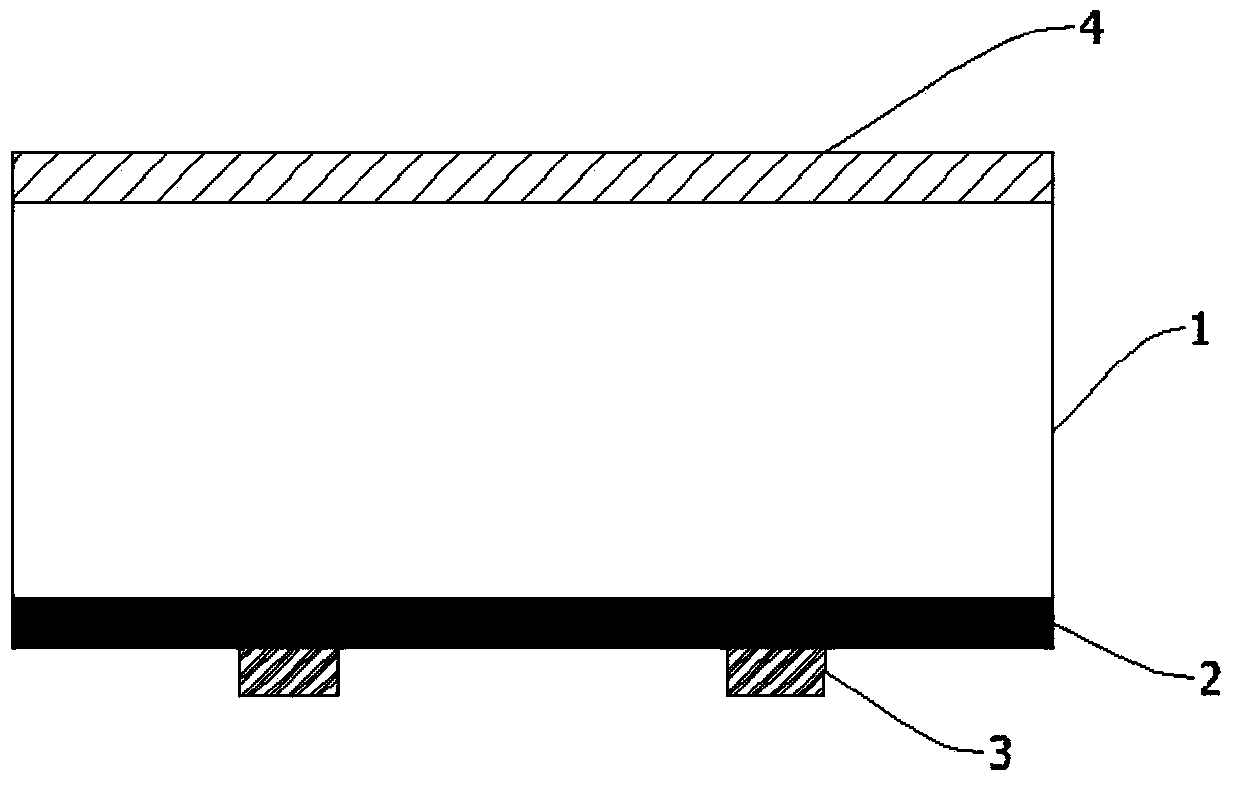

[0035] Such as figure 1 As shown, the main body of the crystalline silicon sample to be processed is a Si base, a silicon nitride layer is deposited on the front side, and a sample with an Al back field structure on the back side.

[0036] 1. A mask with openings is covered on the surface of the silicon nitride layer as a protective film, and the positions of the openings correspond to the positions of gate lines to be etched. Methods as below:

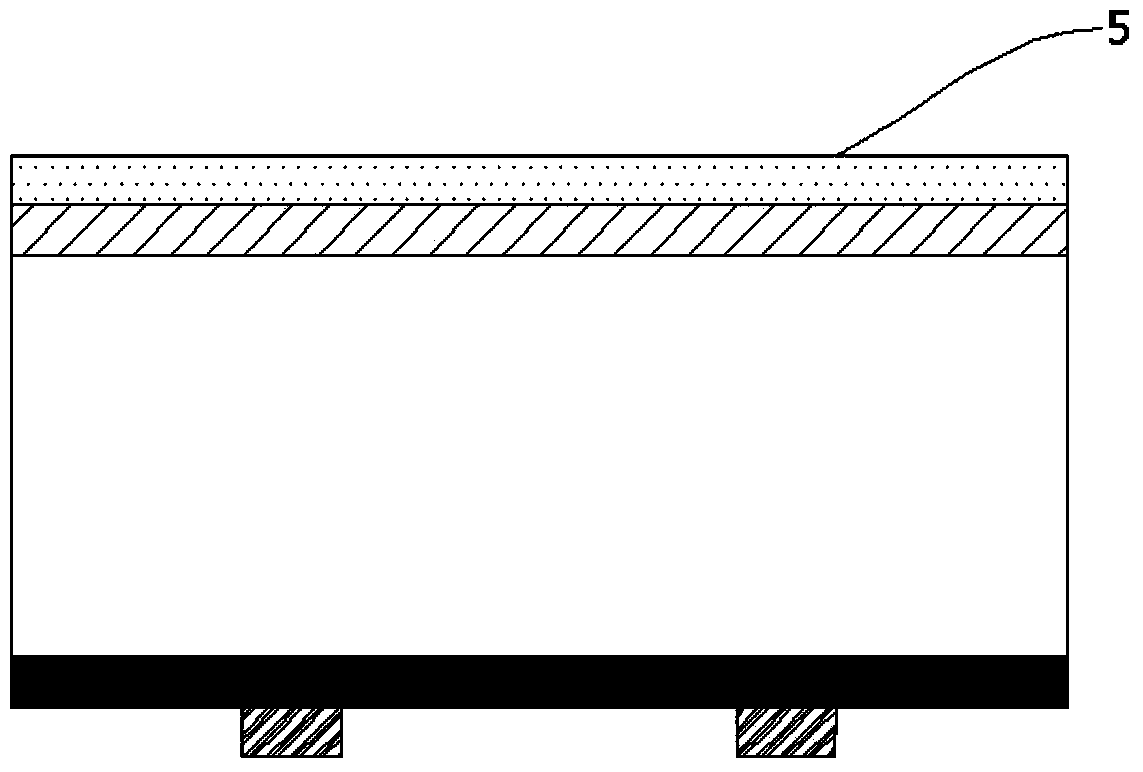

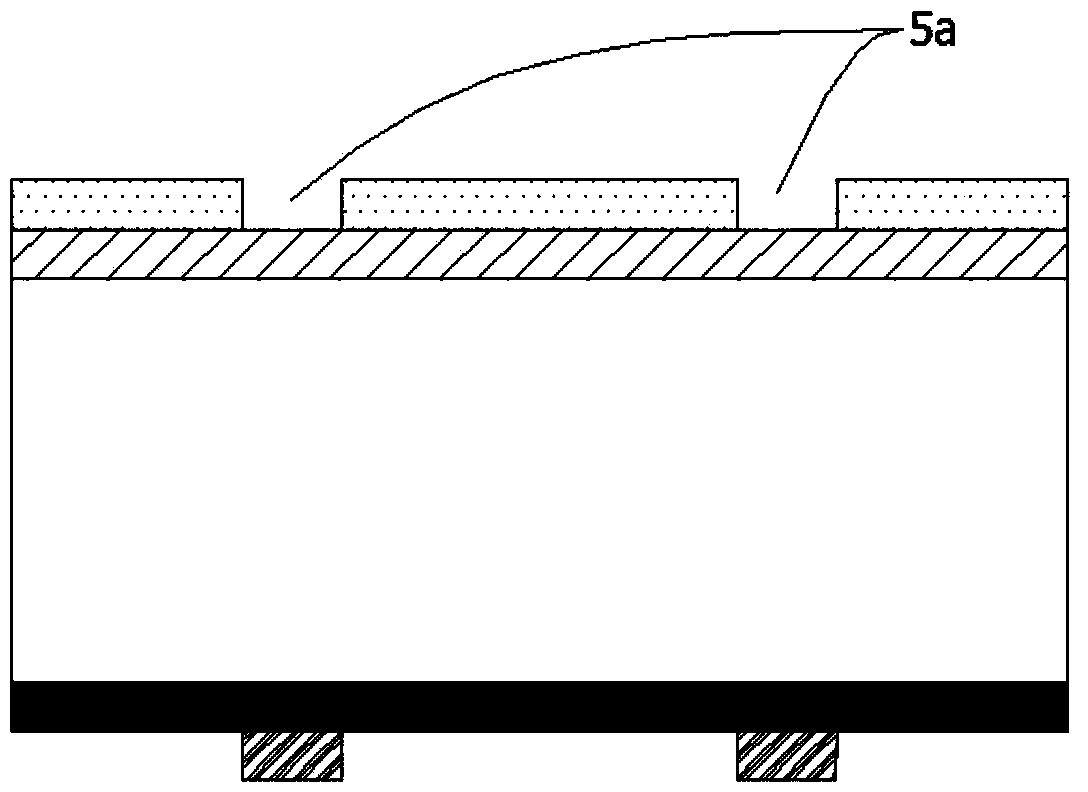

[0037] (1) if figure 2 As shown, the surface of the silicon nitride layer of the sample is first covered with a whole layer of photosensitive protective film material, and then the sample is placed in an exposure machine for exposure, and the protective film material at the position of the gate line is removed by development to form the window with a window. Protective film; the protective film used in this scheme is dry film or other photosensitive materials, and the protective film is covered by lamination method, coating method...

Embodiment 1

[0065] Embodiment 1: This embodiment is an improved copper electroplating method for crystalline silicon cells, and the following steps are performed:

[0066] (1) Lamination method to cover the protective film. The protective film uses acid-resistant negative adhesive dry film, which is composed of protective film polyethylene, photoresist film and carrier polyester film;

[0067] (2) Exposure and development. The developer is 0.3-4% NaOH solution; the state of the sample after this step is as follows image 3 shown;

[0068] (3) Etching. The etching solution is 10%-35% hydrofluoric acid, and the time is 2-60min; the state of the sample after completing this step is as follows Figure 4 shown;

[0069] (4) Plating barrier layer. The material is Ni, the electroplating method is used, photocatalysis is added, and the sample is placed horizontally; the electroplating anode is a nickel strip, the electroplating temperature is 35-65°C, and the electroplating time is 0-500sec...

Embodiment 2

[0073] Embodiment 2: This embodiment is an improved copper electroplating method for crystalline silicon cells, and the steps different from Embodiment 1 are:

[0074] (1) Plating barrier layer. The material is Ni, using electroless plating, adding photocatalysis, and the sample is placed horizontally; the electroless plating solution is sodium hypophosphite solution; the temperature is 30-95°C, and the time is 0.5-30min;

[0075] (2) Increase the anti-oxidation layer. The material is Sn, the electroplating method is adopted, and the sample is placed horizontally; the electroplating solution is methanesulfonate;

[0076] All the other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com