Structure of device for detecting tubeless steel ring gastightness

A technology of air tightness detection and detection process, which can be used in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, and measuring the increase and deceleration rate of fluid, etc., can solve the problem of not perfect tubeless. The detection method of the steel rim air tightness testing equipment, the late start of the application of tubeless wheels, and the limited amount of use have achieved the effects of improving the production technology of tubeless steel rims, reducing the product scrap rate, and improving the economic benefits of the enterprise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

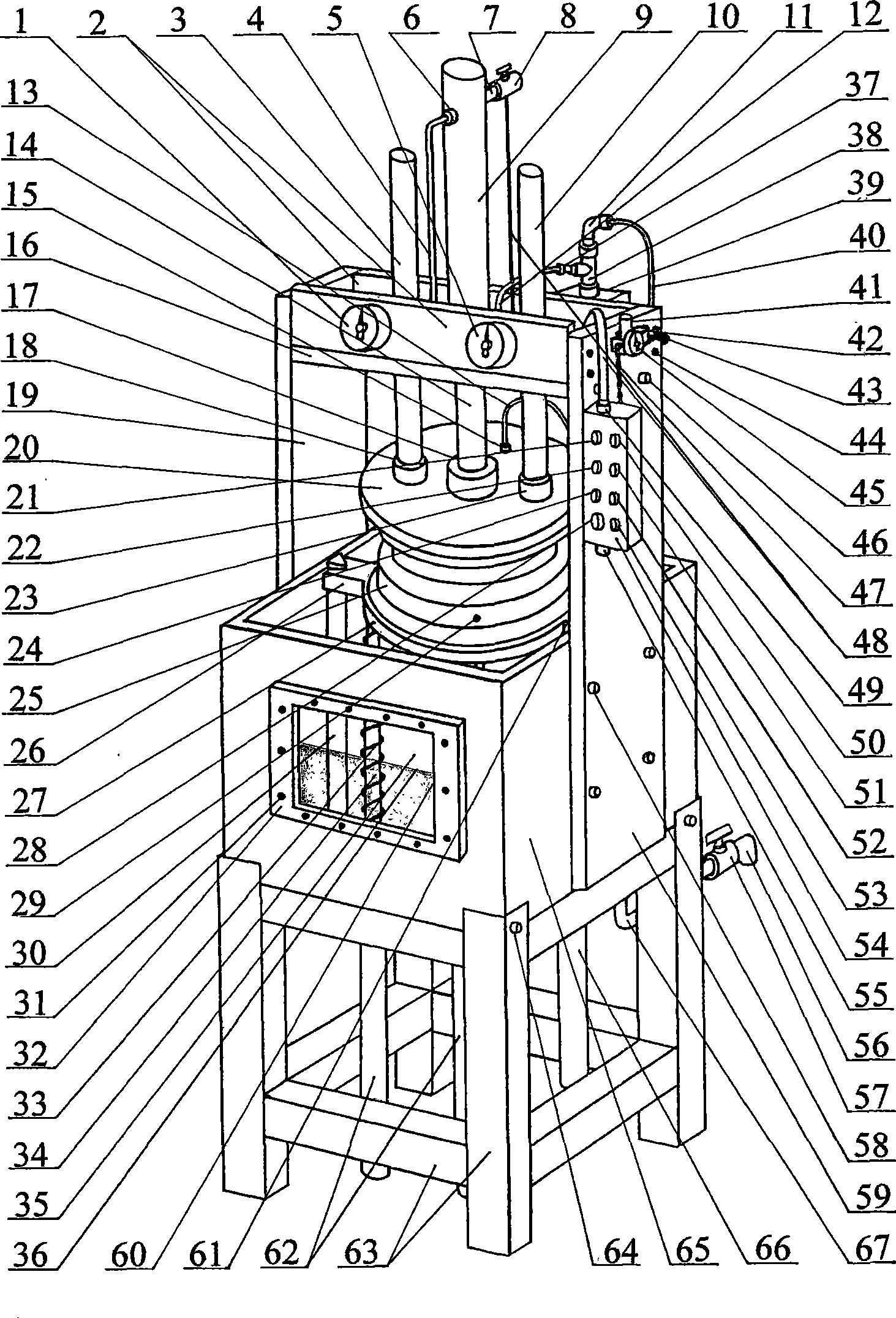

[0014] The structure and testing process of the tubeless rim airtightness testing equipment, as shown in the figure, includes the structure of the tubeless rim airtightness testing equipment and the tubeless rim airtightness testing process.

[0015] The structure of the air tightness testing equipment for tubeless rims is as shown in the figure:

[0016] First, separate the components of the body, and divide the parts that make up the air tightness testing equipment for tubeless rims into upper frame, lower frame, water tank, pressure plate, tray, and control box, among which:

[0017] The upper frame assembly is mainly composed of beam columns 19 and 59, beams 16 and 2, screws 58 and 46, and screws 44; beam columns 19 and 59 follow beams 16 and 2, and screws 46 and 44 pass through the beam columns 19 and 59 are connected in the way that the end face ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com