Steeltried wheel rim burr treatment process and device

A technology for processing equipment and construction methods, which is applied in the field of automobile steel ring production, and can solve the problems of lack of perfect steel ring rim burr treatment technology, insufficient attention to the beauty of steel rings, affecting the appearance of steel ring products and airtight technical performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

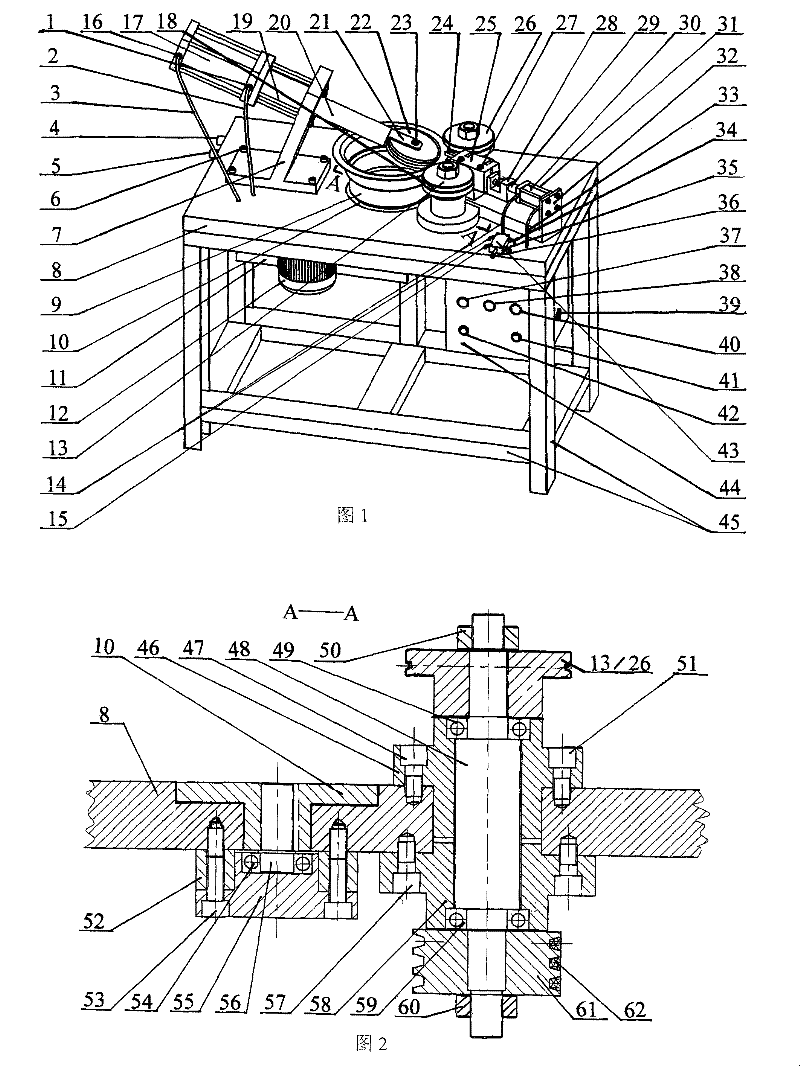

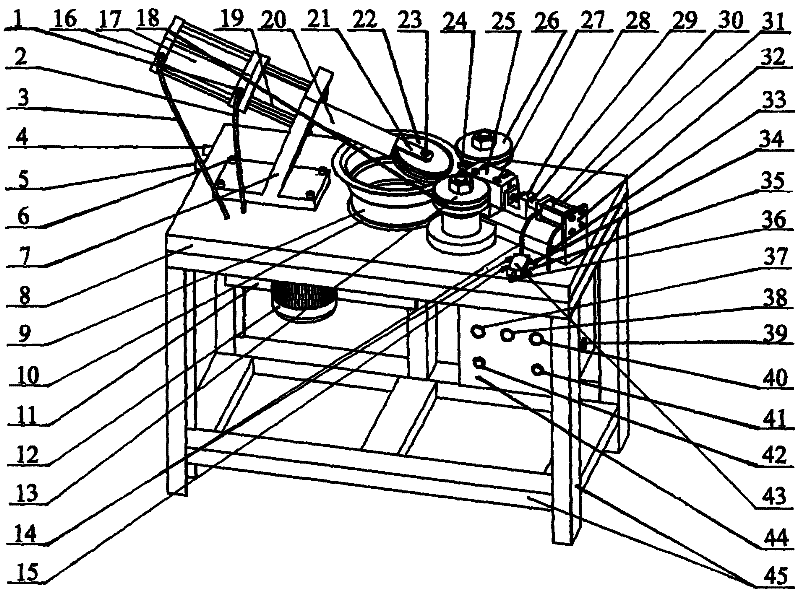

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0011] The present invention, such as figure 1 As shown in Figure 2, including the construction method of the steel ring rim burr processing equipment and the steel rim burr processing process: the construction method of the steel rim rim burr processing equipment, firstly the parts that make up the steel rim rim burr processing equipment , divided into frame assembly, pressure wheel assembly, turntable assembly 10, guide wheel assembly 13 and 26, cutter assembly, and then configure electrical box assembly, motor 12 and transmission mechanism, air valve assembly 43, and then connect each assembly, with cylinder The fixed frame 7 is placed on the top surface of the platen 8 and fixed with screws, the pressure wheel assembly is arranged on the frame assembly, and the fixed seat 52 and the bottom cover 55 are fixed on the bottom surface of the platen 8 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com