A kind of plum blossom inner hexagonal punching needle and preparation method of needle

A technology of punching pins and plum blossoms, which is applied in the field of metal stamping, can solve the problems of fast solidification, poor fluidity, and burrs, and achieve the effects of good product consistency, reduced production costs, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] M6 plum-blossom inner hexagonal punching needle and the preparation method of the needle head

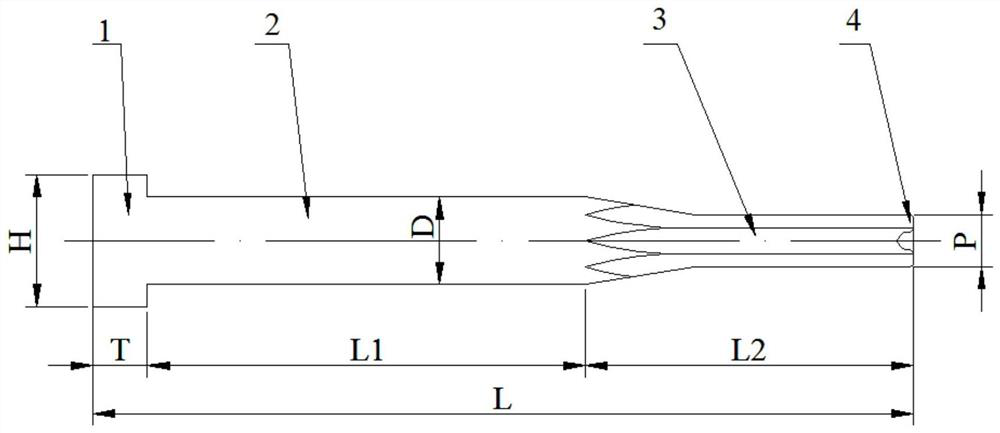

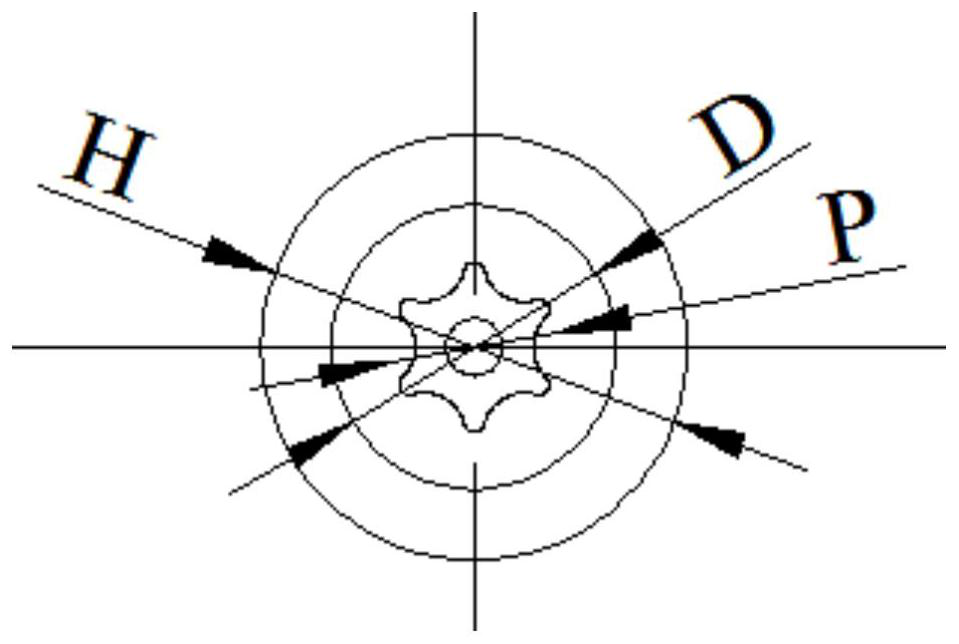

[0035] A kind of M6 plum blossom inner hexagonal punching needle, the plane front view is as follows figure 1 As shown, the plane right view is as figure 2 As shown, the punching needle is an A-type punching needle, including a T head 1, a needle bar 2 and a needle head 3. The dimensions of each part of the punching needle are L1:L2=4:3, H=2.5P=1.5D, P=6mm, T / P=1.04, and the plum blossom structure 4 on the front end of the needle head 3 has a depth of 2mm, 3mm diameter concave hole; where T, L1, L2 represent the lengths of T head 1, needle bar 2, and needle head 3 respectively; H, D, and P represent the diameters of T head 1, needle bar 2, and needle head 3.

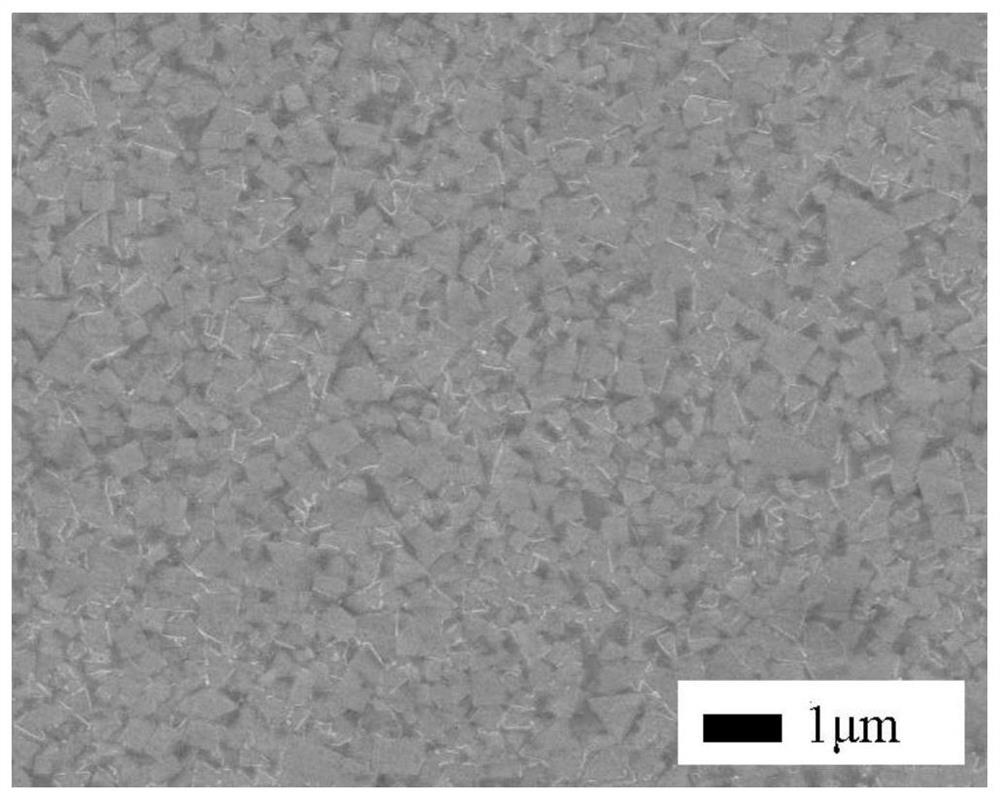

[0036] The material of the T head 1 and the needle bar 2 is high-speed steel, and the material of the needle 3 is WC-Co hard alloy, and the two parts are connected by welding wire. Among them, the raw material compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com