Microwave vacuum device for drying and charring lumber

A microwave vacuum drying and carbonization device technology, applied in wood treatment, humidity control wood, wood processing equipment, etc., can solve the problems of increased wood loss, carbonized wood bursting, poor carbonization uniformity, etc., to speed up carbonization speed and reduce wood loss , The effect of improving moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

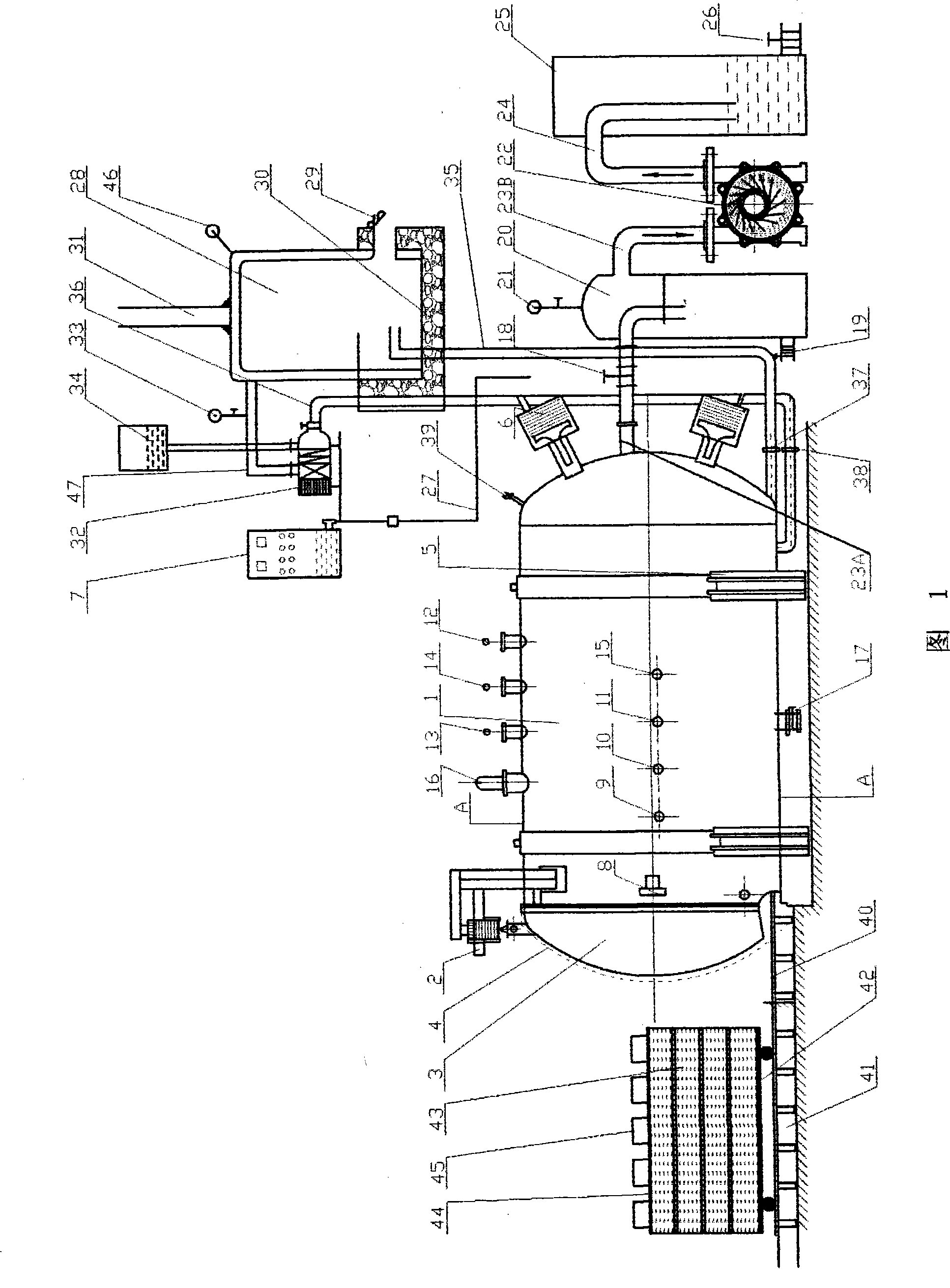

[0048] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

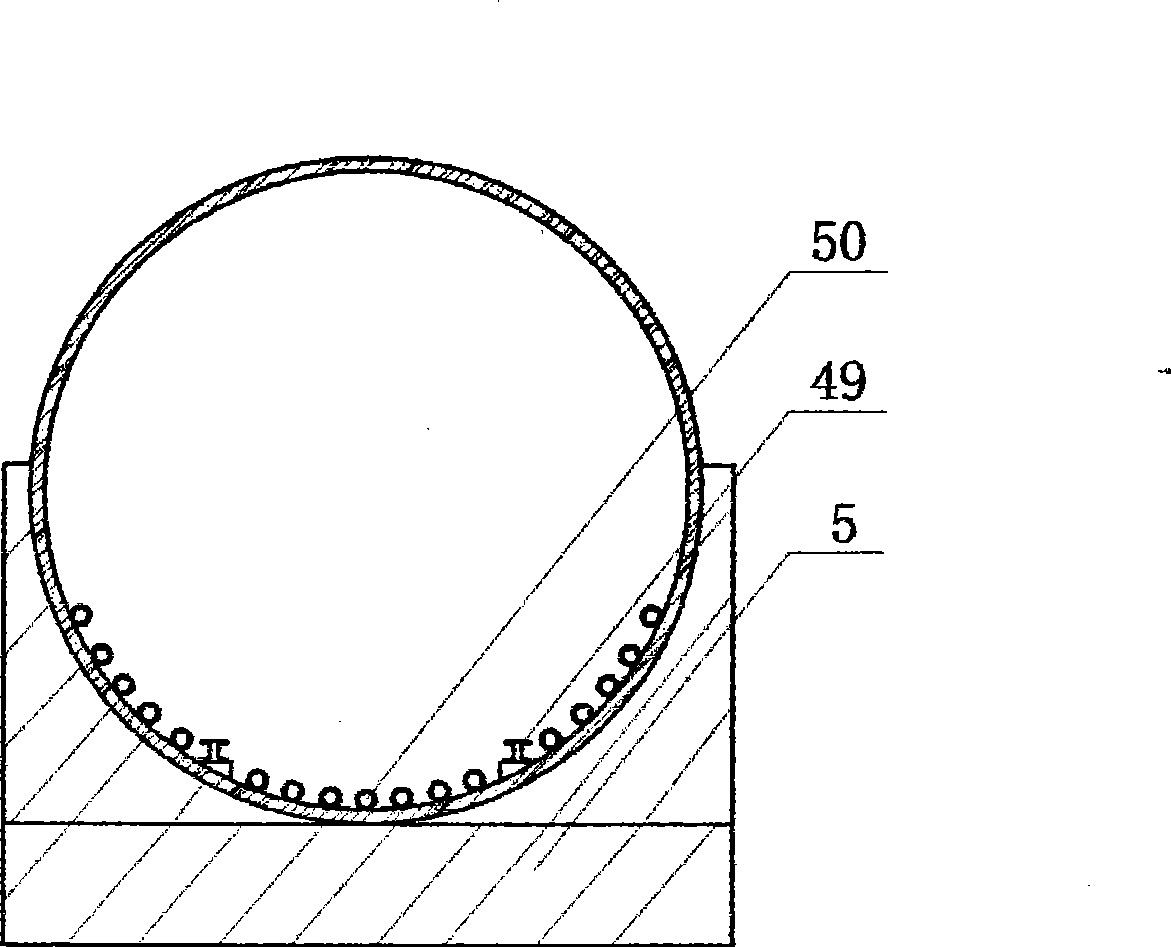

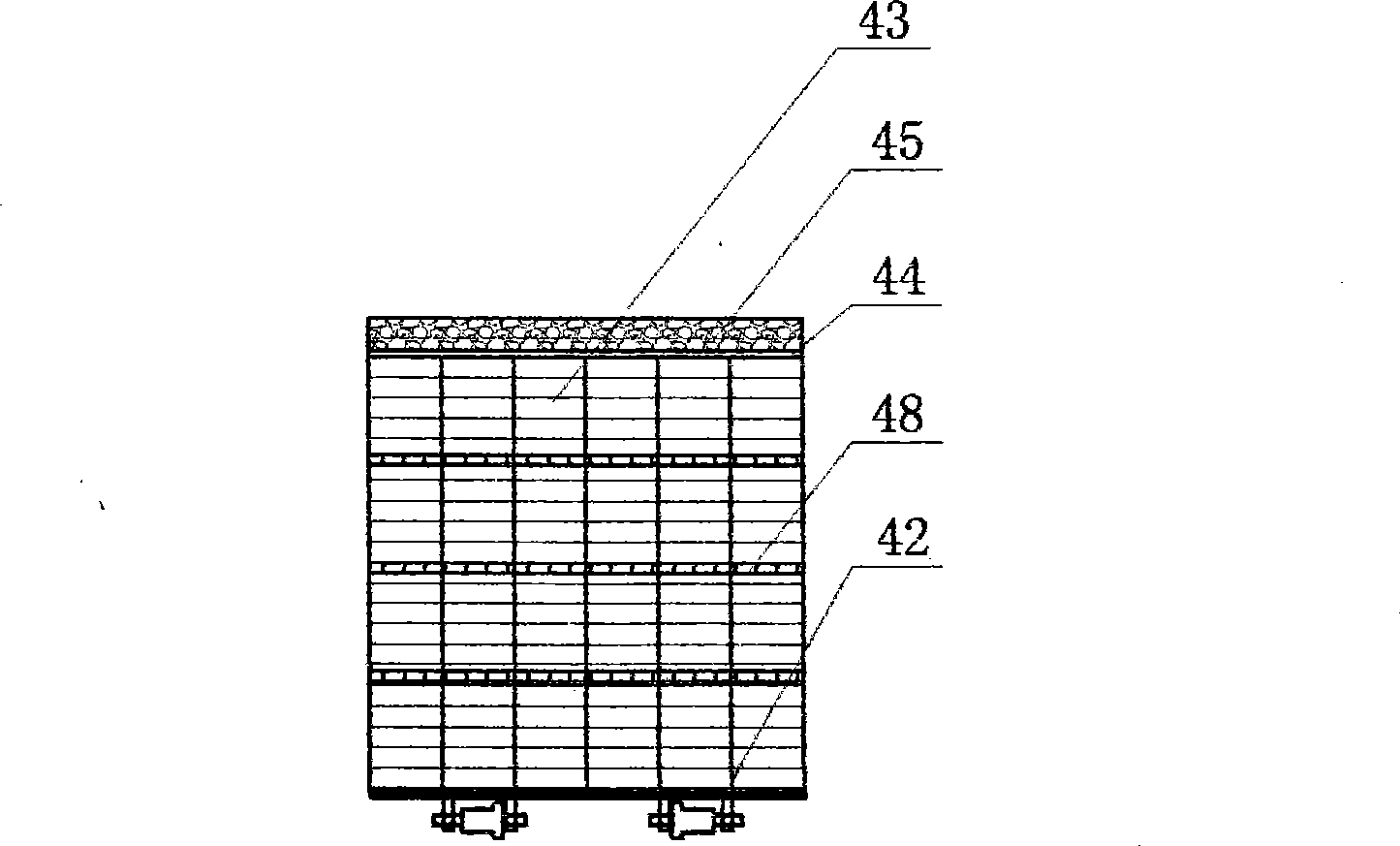

[0049] As shown in Figure 1-3, the wood microwave vacuum drying and carbonization device includes: a carbonization tank (box) with a tank door (3) and a tank door opener (2) and a carbonization chamber (1), a vacuum system , also includes one or more microwave sources (6) for generating microwaves, a heat conduction oil furnace system, and a material preparation and feeding system.

[0050] A microwave protection net (4) is provided on the tank door (3) of the carbonization tank (box) of the wood drying and carbonization device, and a safety locking device (8) is provided on the wall of the tank (box) body to control the opening of the tank door and closing, generation and closing of microwaves and removal of air in the carbonization chamber (1). The temperature thermocouple (9), pressure thermocouple (10), vacuum thermocouple (11) and material moisture analy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com