Method of using eucalyptus to make formaldehyde-free veneer laminated lumber

A technology of laminated veneer and eucalyptus, which is used in the joining of wooden veneers, moisture-conditioning wood, manufacturing tools, etc. The effect of economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: a kind of method of making formaldehyde-free laminated veneer with eucalyptus wood, comprises following operation:

[0016] ①, Medium and small-diameter eucalyptus logs are peeled and cut to make eucalyptus veneers with a thickness of 2.4mm, a length of 1270mm, and a width of 320mm or 640mm;

[0017] ②, the eucalyptus veneer is dried in a dryer, and the moisture content of the veneer is controlled below 12%;

[0018] ③. Place the eucalyptus veneer in a carbonization kiln for carbonization treatment at a temperature of 200°C for 2 minutes;

[0019] ④, use starch adhesive on the veneer after carbonization, and glue it on the glue machine, and the amount of glue is controlled at 300g / square meter on both sides; the proportion and preparation of starch adhesive are in the patent number: CN201010171082.8 documented in patent documents.

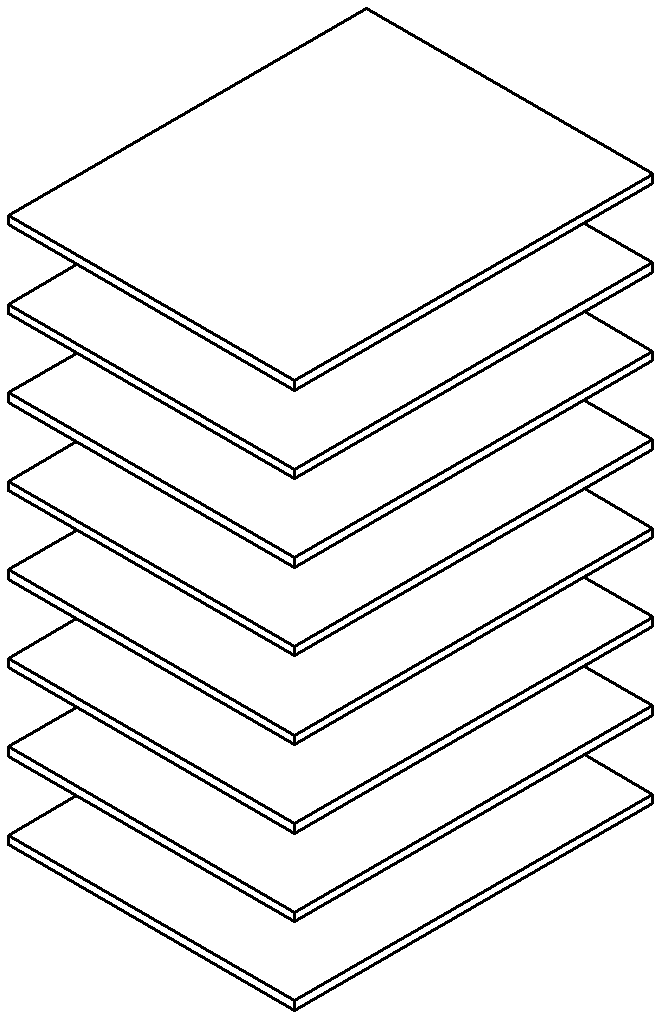

[0020] ⑤, Blank assembly: the glued eucalyptus veneer is made into a group of 8 layers, such as figure 1 As shown, the gra...

Embodiment 2

[0024] Embodiment 2: a kind of method of making formaldehyde-free laminated veneer with eucalyptus wood, comprises following operation:

[0025] ①, Medium and small-diameter eucalyptus logs are peeled and cut to make eucalyptus veneers with a thickness of 3.0mm, a length of 1300mm, and a width of 320mm or 640mm;

[0026] ②, the eucalyptus veneer is dried in a dryer, and the moisture content of the veneer is controlled below 12%;

[0027] ③. Place the eucalyptus veneer in a carbonization kiln for carbonization treatment at a temperature of 220°C for 3 minutes;

[0028] ④, use starch adhesive on the veneer after carbonization, and glue it on the glue machine, and the amount of glue is controlled at 320g / square meter on both sides; the proportion and preparation of starch adhesive are in the patent number: CN201010171082.8 documented in patent documents.

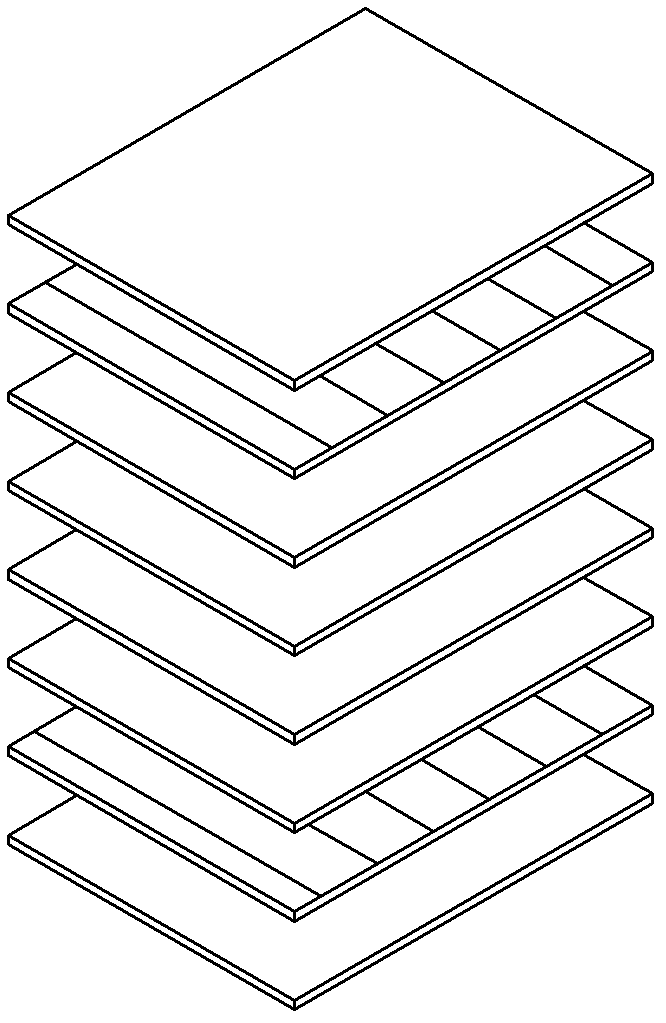

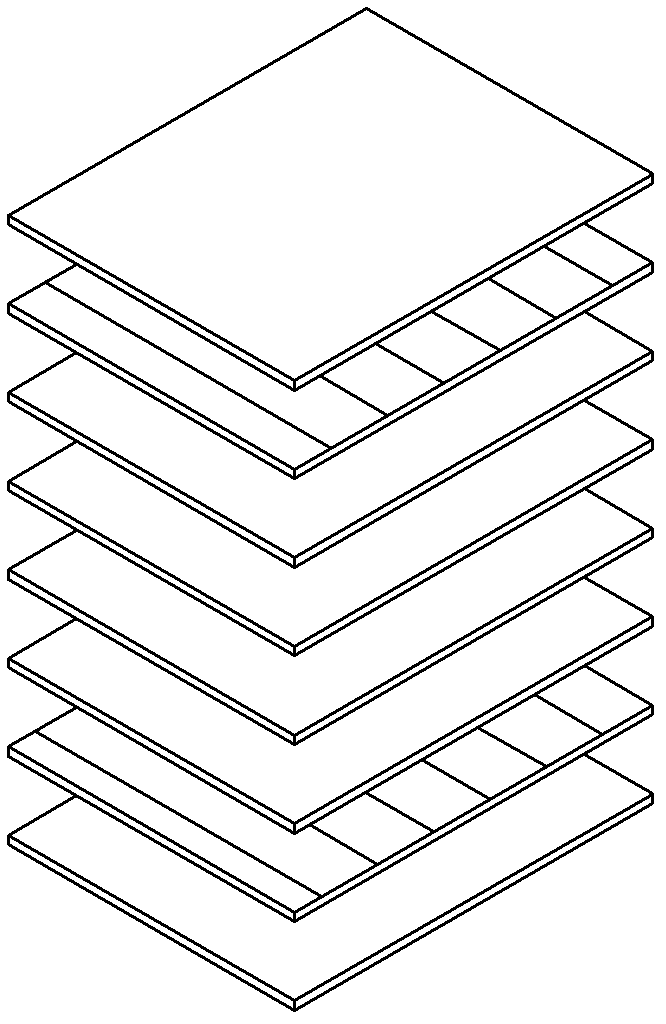

[0029] ⑤, Blank assembly: the glued eucalyptus veneer is made into a group of 8 layers, such as figure 2 As shown, in eac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com