Method for processing wood and wood manufactured by same

A processing method and technology for wood, applied in the direction of wood treatment, wood treatment details, humidity-conditioning wood, etc., can solve the problems of undiscovered research literature and patent applications, wood prone to cracking, shrinkage, and difficult wood quality and control, etc. Achieve low cost wood treatment, maintain color and appearance, and achieve the effect of degreasing treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Palletizing

[0029] Larix boards with an initial moisture content of 50%, a thickness of 40mm, a length of 2000mm, and a width of 100mm are stacked according to the wood drying method and placed in a closed pressure-resistant high-temperature heat treatment equipment;

[0030] 2. Decompression and vacuuming

[0031] Under 25 ℃, the larch wood inside the pressure-resistant high-temperature heat treatment equipment is subjected to decompression and vacuum treatment, so that the absolute pressure inside the equipment reaches and maintains 0.01MPa (that is, the relative vacuum degree is -0.09MPa). After keeping at 0.01MPa for 25 minutes, turn off the vacuum pump and stop vacuuming;

[0032] 3. Preheating treatment

[0033] Feed saturated water vapor into the pressure-resistant high-temperature heat treatment equipment. When the absolute pressure in the equipment reaches 0.1MPa, stop feeding saturated water vapor, and then turn on the heating system to preheat the wood...

Embodiment 2

[0044] Except that the absolute pressure inside the equipment during decompression and vacuum treatment is 0.02MPa, the decompression and vacuum treatment time is 60 minutes; the temperature inside the equipment during preheating treatment is 95°C, preheating to the temperature of the wood surface and the center of the wood The temperature difference is ≤4°C; the absolute pressure inside the equipment is 0.4MPa during the high-temperature pressurized drying process, the pressurized drying temperature is 130°C, and the heating and heating rate is 10°C / h; the absolute pressure inside the equipment during the high-temperature pressurized heat treatment process is The pressure is 0.5MPa, the heat treatment temperature is 200°C, the heating rate is 20°C / h, and the heat treatment time is 4 hours; during the humidity control process, saturated water vapor with an absolute pressure of 0.1MPa is introduced to make the temperature of the wood in the equipment After lowering to 100°C, tur...

Embodiment 3

[0047] Except that the absolute pressure inside the equipment is 0.4MPa during the high-temperature pressurized heat treatment process, the heat treatment temperature is 180°C, the heating and heating rate is 10°C / h, and the heat treatment time is 4 hours; After saturating the water vapor to reduce the temperature of the wood in the equipment to 100°C, turn on the condensation system to cool the wood in the equipment so that the temperature of the wood inside the equipment is 75-85°C until the moisture content of the wood reaches 9%. Except, the others are the same as in Example 1.

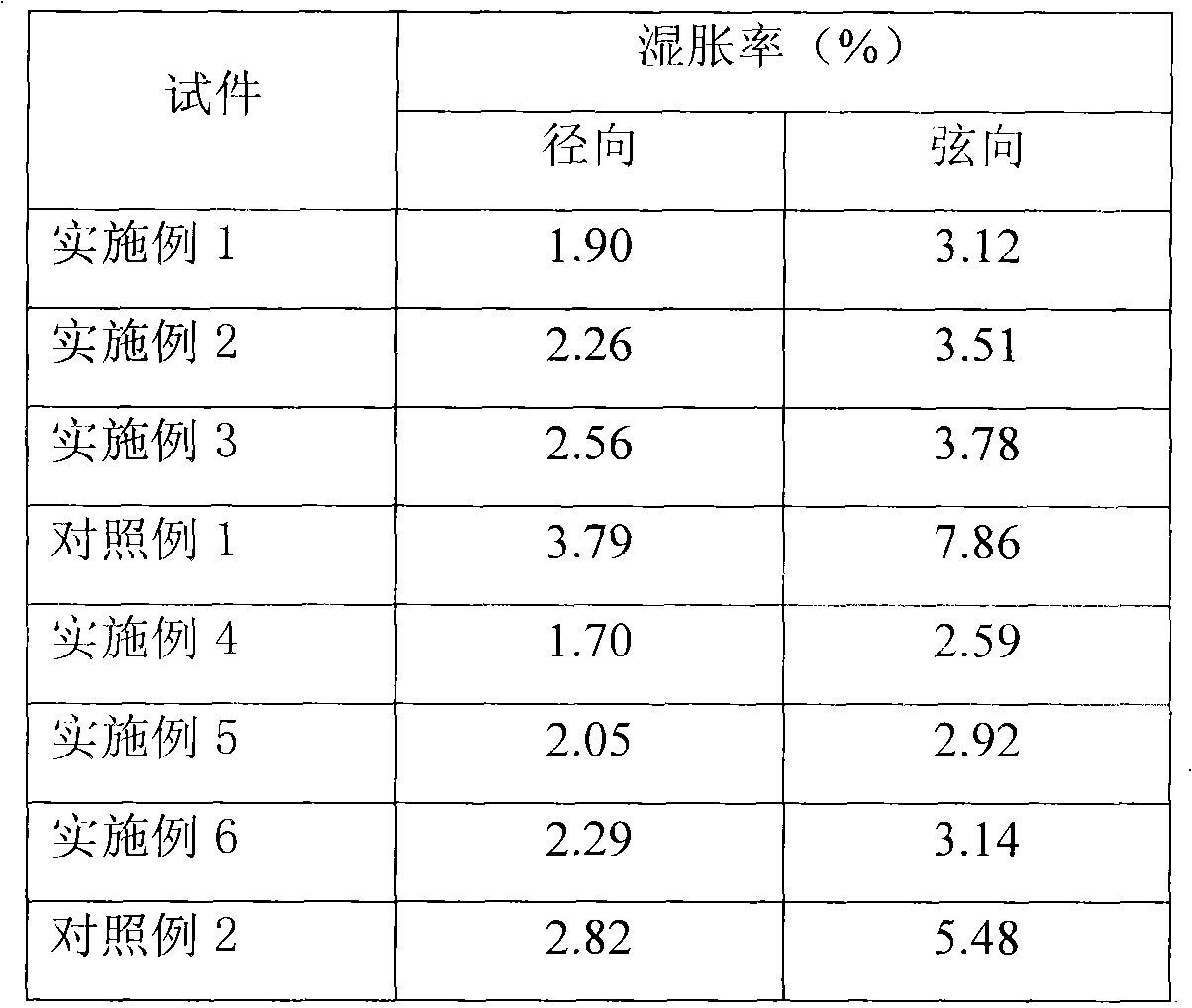

[0048] Determination of the density of modified wood according to the national standard GB1933-91 "Determination of Timber Density Method", GB1935-91 "Test Method for Compressive Strength of Wood along the Grain" to determine the compressive strength of modified wood, GB1936-91 "Test Method for Bending Strength of Wood" "Determination of the flexural strength of modified wood, GB1937-91 "Test meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com