Ammonium polyphosphate/SiO2 composite aerogel flame-retardant reinforced timber and preparation method thereof

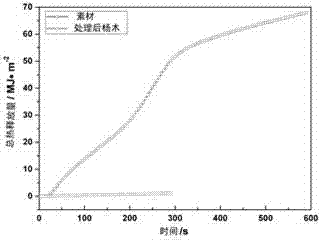

A composite airgel and ammonium polyphosphate technology, applied in wood treatment, wood heating, wood humidity control, etc., can solve the problems of affecting decoration, a large amount of smoke, loss, etc., and achieve good heat insulation and flame retardant effect, good The effect of synergistic flame retardancy and permeability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

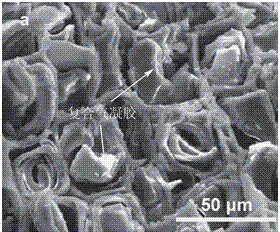

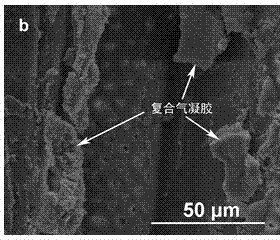

[0032] A kind of ammonium polyphosphate / SiO 2 Composite airgel-type flame retardant reinforced poplar wood, including poplar wood, and ammonium polyphosphate / SiO present in the pores of poplar wood 2 Composite airgel; where poplar wood and ammonium polyphosphate / SiO2 The mass ratio of the composite airgel is 100:18.

[0033] Ammonium Polyphosphate / SiO in Wood Pores 2 Composite airgel is made by first placing the wood in the homogeneous mixed sol solution of the hydrolyzate of ammonium polyphosphate and silicon source under acidic conditions, so that the hydrolyzate of the two is introduced into the wood channel, and then the wood is taken out and dried. After soaking in lye to make condensation between the two hydrolyzates, the wood is finally taken out to dry the ammonium polyphosphate / SiO produced in situ by the condensation of the hydrolyzate in the wood pores 2 Composite airgel;

Embodiment 1

[0034] A kind of ammonium polyphosphate / SiO 2 The first embodiment of the preparation method of composite airgel type flame retardant reinforced poplar wood comprises the following steps:

[0035] (1) Dry the wet poplar wood (1000mm long, 150mm wide, and 30mm thick) in a conventional drying room to a moisture content of 45%, and then use high-intensity microwave pretreatment equipment to perform microwave puffing treatment on the above-mentioned poplar sawn timber. The temperature of puffing treatment is controlled at 145°C, and the time of microwave pretreatment is controlled at 18s; then, the above-mentioned poplar sawn timber after microwave puffing pretreatment is dried to 14% in a conventional drying room, and set aside;

[0036] (2) Take a container to prepare 1260g of ammonium polyphosphate aqueous solution with a mass percentage of 30%, then use phosphoric acid to adjust the pH value of the solution to 4, and wait for use; then take another container and add 104g ortho...

Embodiment 2

[0040] A kind of ammonium polyphosphate / SiO 2 Composite airgel-type flame retardant reinforced poplar wood, including poplar wood, and ammonium polyphosphate / SiO present in the pores of poplar wood 2 Composite airgel; where poplar wood and ammonium polyphosphate / SiO 2 The mass ratio of the composite airgel is 100:22.

[0041] Ammonium Polyphosphate / SiO in Wood Pores 2 Composite airgel is made by first placing the wood in the homogeneous mixed sol solution of the hydrolyzate of ammonium polyphosphate and silicon source under acidic conditions, so that the hydrolyzate of the two is introduced into the wood channel, and then the wood is taken out and dried. After soaking in lye to make condensation between the two hydrolyzates, the wood is finally taken out to dry the ammonium polyphosphate / SiO produced in situ by the condensation of the hydrolyzate in the wood pores 2 Composite airgel;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com