Processing method of high-strength E0 grade middle-high density plate

A technology of high-density boards and processing methods, applied in wood processing appliances, manufacturing tools, wood treatment, etc., can solve the problems of high curing temperature, difficult balance, and slow curing speed of phenolic resin, and achieve low content of free aldehydes and free phenols , The production process is stable and the effect of good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

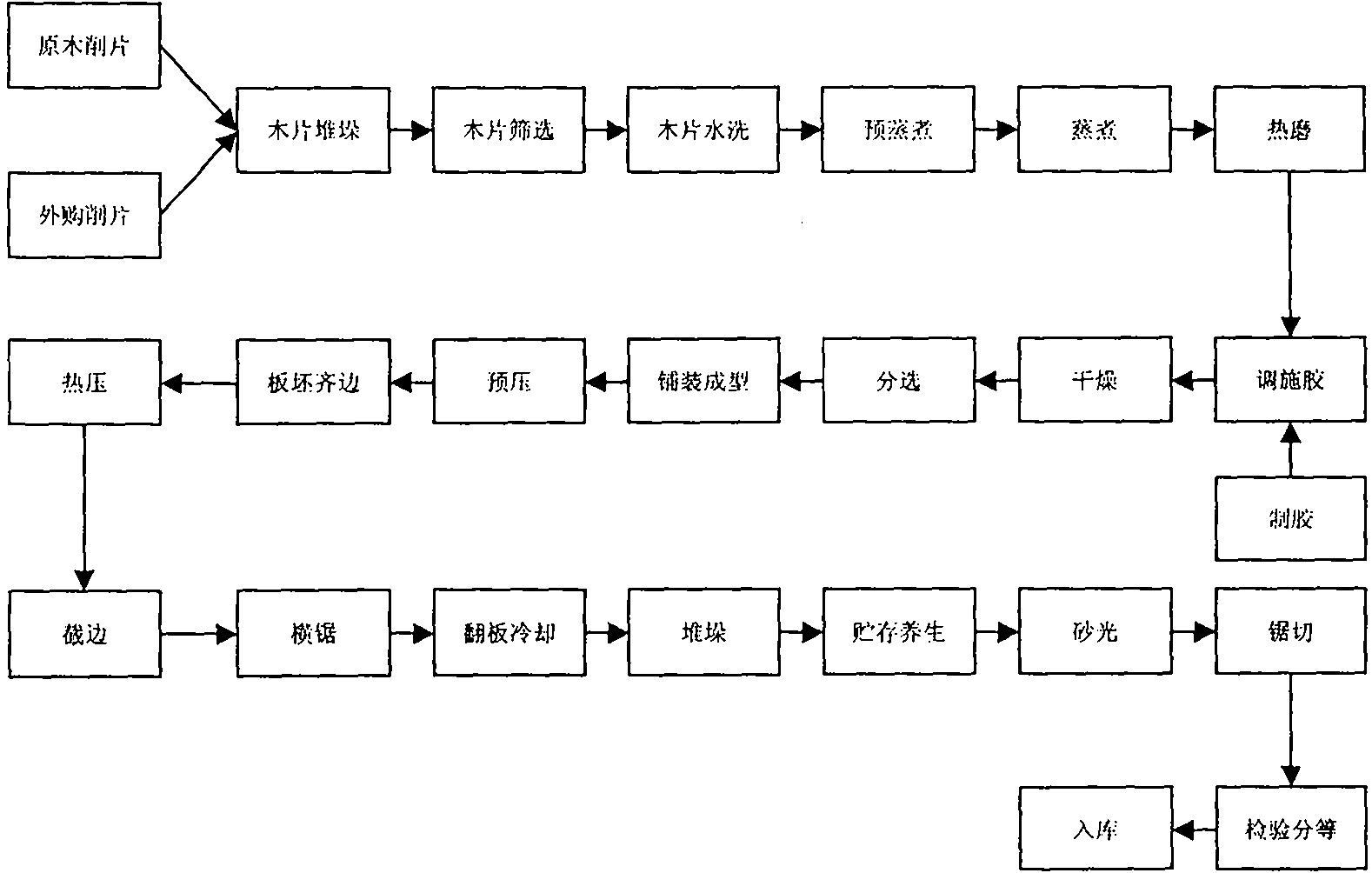

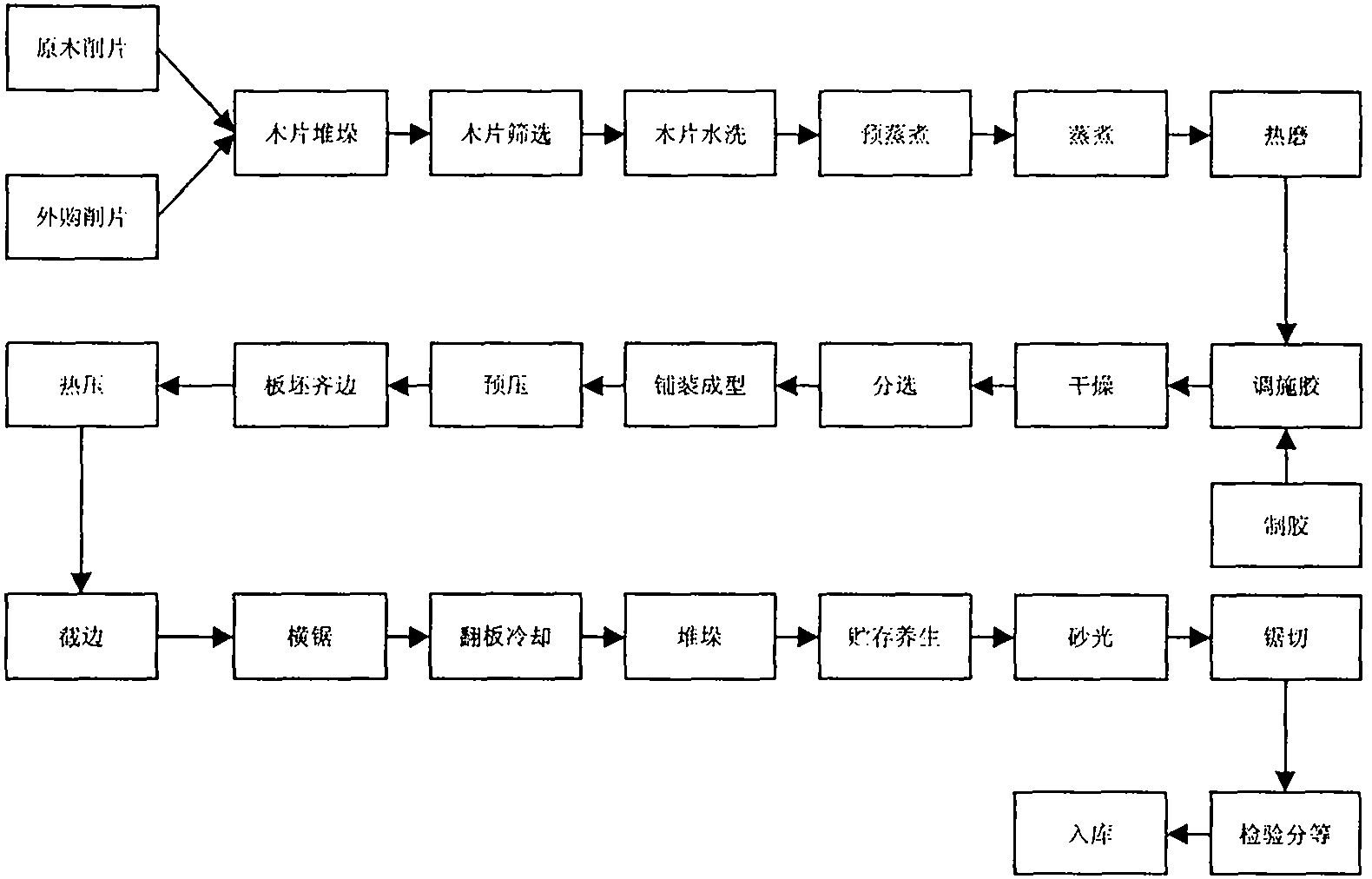

Image

Examples

Embodiment 1

[0010] Embodiment 1: Wash the clean logs with a length of 40 mm, a width of 15 mm, and a thickness of 2 mm to remove impurities such as silt on the surface of the wood chips. The washed wood chips are sent to the pre-cooking vat by the wood chip pump for initial softening, and then sent to the cooking vat for further softening through the cork screw. The steam pressure in the cooking vat is 0.70Mpa, and the pressure of the grinding chamber is about 0.01Mpa lower than that of the cooking vat. The grinding quality of the fiber is improved through the pressure difference, and the cooking time is 3 minutes. After the wood chips are fully cooked, they enter the grinding chamber of the heat refiner to defiber. The fiber is applied with modified phenolic resin according to the ratio of solid modified phenolic resin glue to 12% of the absolute dry fiber mass, and the solid paraffin is applied according to the amount of 0.5% of the absolute dry fiber mass. Applying, the mass of the liq...

Embodiment 2

[0011] Embodiment 2: Wash the clean logs with a length of 60 mm, a width of 30 mm, and a thickness of 6 mm to remove impurities such as silt on the surface of the wood chips. The washed wood chips are sent to the pre-cooking vat by the wood chip pump for initial softening, and then sent to the cooking vat for further softening through the cork screw. The steam pressure in the cooking vat is 0.80Mpa, and the pressure of the grinding chamber is about 0.02Mpa lower than that of the cooking vat. The grinding quality of the fiber is improved through the pressure difference, and the cooking time is 5 minutes. After the wood chips are fully cooked, they enter the grinding chamber of the thermal refiner to defiber, and the fiber is applied with modified phenolic resin according to the ratio of solid modified phenolic resin glue to 18% of the absolute dry fiber mass, and solid paraffin is applied according to the amount of 1.5% of the absolute dry fiber mass. Applying, the liquid forma...

Embodiment 3

[0012] Embodiment 3: Wash the clean logs with a length of 50 mm, a width of 20 mm, and a thickness of 5 mm to remove impurities such as silt on the surface of the wood chips. The washed wood chips are sent to the pre-cooking vat by the wood chip pump for initial softening, and then sent to the cooking vat for further softening through the cork screw. The steam pressure in the cooking vat is 0.75Mpa, and the pressure of the grinding chamber is about 0.015Mpa lower than that of the cooking vat. The grinding quality of the fiber is improved through the pressure difference, and the cooking time is 5 minutes. After the wood chips are fully cooked, they enter the grinding chamber of the thermal refiner to defiber, and the fiber is applied with a modified phenolic resin according to the ratio of the solid modified phenolic resin glue to 15% of the dry fiber mass, and the solid paraffin is applied according to 1% of the dry fiber mass. Applying, the mass of the liquid formaldehyde sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com