Composite section material for coating wood surface on surface of plastic/wood-plastic sectional material and manufacturing method therefor

A wood-plastic profile and surface coating technology, which is applied to the jointing of wooden veneers, humidity control of wood, and manufacturing tools, etc., can solve the problems of slow curing speed, easy-to-produce defective bonding, and infirmity of the adhesive film, and achieve Fast curing speed, improved interface affinity, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

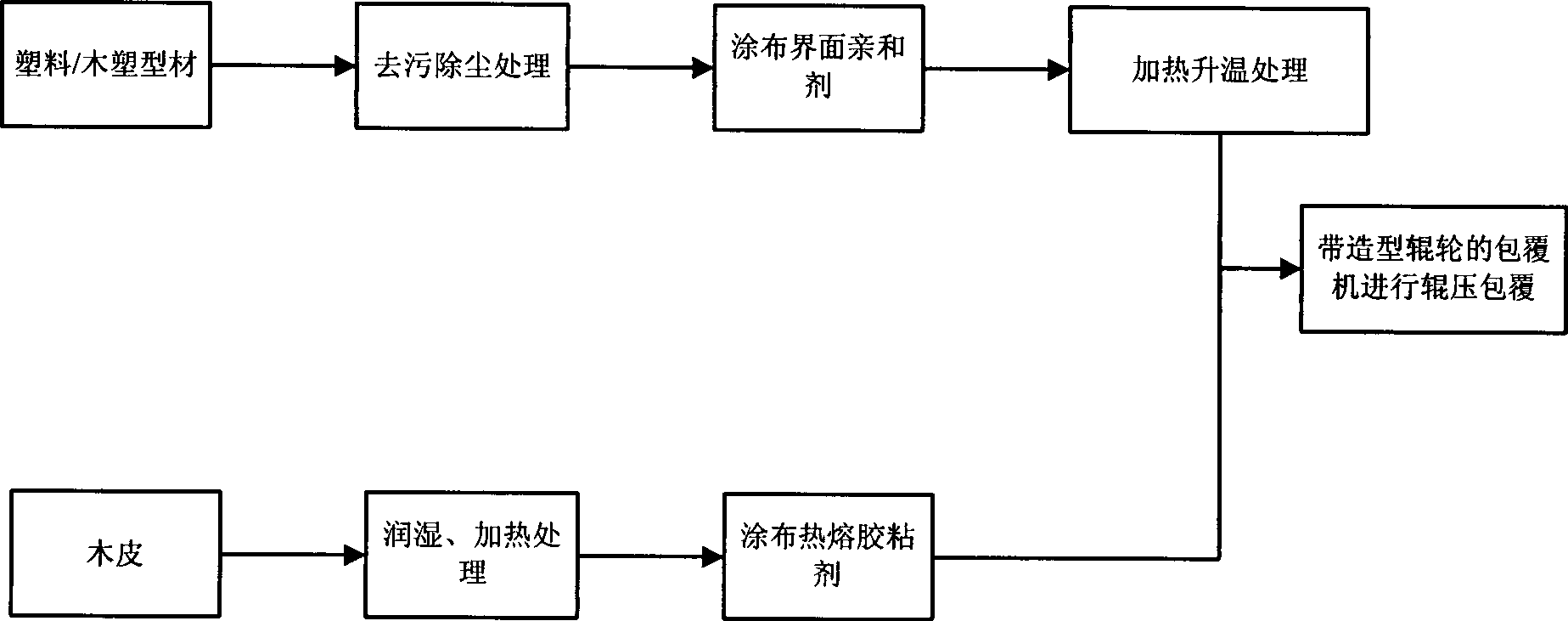

Method used

Image

Examples

Embodiment 1

[0030] (1) Decontamination and dust removal treatment is performed on the ABS (acrylonitrile-styrene-butadiene copolymer) profiles, that is, the dust attached to the surface of the profile to be coated is sucked out through the suction device, which is beneficial to the surface of the profile and the veneer in the subsequent process the gluing;

[0031] (2) The main component is the interface affinity agent of polycondensation resin and chlorinated hydrocarbon to the coating surface to be coated of the ABS profile after dedusting;

[0032] (3) While performing steps (1) and (2), apply PUR hot-melt adhesive to the inner surface of the veneer with a thickness of 0.15 mm. The melting temperature of PUR hot-melt adhesive is 110 ° C, and its coating temperature is 120 ° C. ℃, glue amount is 90g / m 2 ;

[0033] (4) to the ABS profiles processed through steps (1) and (2) and the wood veneer processed through step (3), roll-press coating by the cladding machine with molding rollers, ...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is that a non-woven fabric layer is added to the inner surface of the veneer, and correspondingly, the glue-coating treatment on the inner surface of the veneer is carried out on the non-woven fabric layer. In addition, the ABS composite profiles coated with veneer that have been processed through steps (1) to (4) are also subjected to sawing treatment, and the sawing treatment uses a sawing machine to make its periphery neat, and the length and / or width meet the following requirements: storage and transport requirements.

Embodiment 3

[0037] The difference between this embodiment and Example 2 is that the ABS composite profile covered with wood veneer will also undergo a health preservation stage before leaving the factory. 12 hours.

[0038]In addition, the standing time of the health preservation stage can also be 24 hours, 36 hours, 48 hours, etc. Generally, it depends on the amount of PUR hot melt adhesive applied, so that it can fully react with the moisture in the air, and it can be finished after the reaction is completed. After the health-preserving stage is over, generally, the resting time is 6-48 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com