Full overflow tank type liquid distributor

A liquid distributor and overflow tank technology, applied in the field of packed tower internals, can solve the problems of inability to use high-efficiency structured packing and precise separation, low quality of liquid distribution, and inability to obtain liquid volume, etc. The effect of uniform liquid distribution and stable liquid level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with embodiment and accompanying drawing thereof, the present invention will be further described:

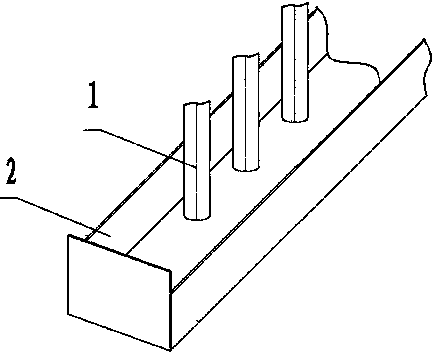

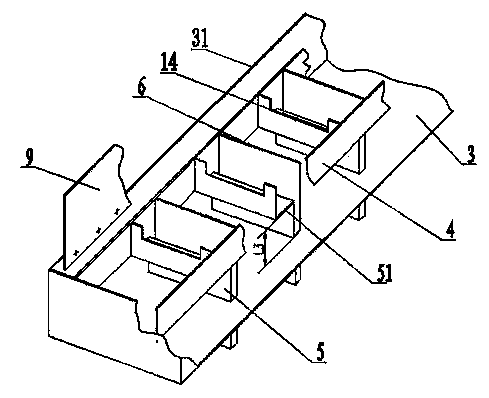

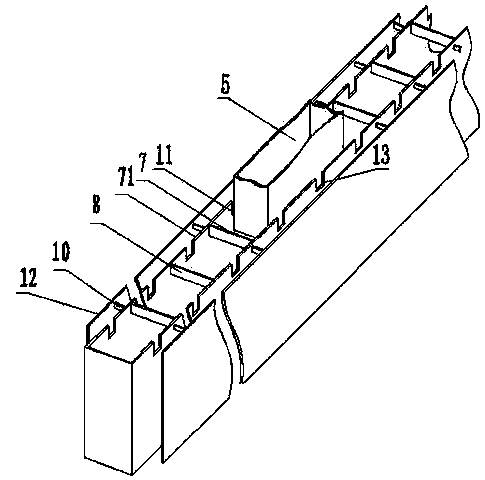

[0025] The full overflow tank type liquid distributor designed by the present invention (distributor for short, see Figure 1-7 ), mainly including liquid distribution pipe 1, buffer tank 2, primary tank 3, liquid distribution box 5, secondary tank 7, baffle plate 9, liquid receiving box 11 and liquid guide plate 12; liquid distribution pipe 1 is cylindrical The structure extends into the buffer tank 2; the buffer tank 2 is installed on the first-level tank 3, one buffer tank 2 corresponds to one first-level tank 3, and the left and right sides of the first-level tank 3 are equipped with baffles 9 respectively, and the baffles 9 and The first-level tank 3 is connected, and its height is slightly higher than the upper surface of the buffer tank 2; the second-level tank 7 is located below the first-level tank 3 and installed vertically with the first-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com