An industrial waste liquid treatment system and method based on carrier gas extraction low-temperature mass transfer

An industrial waste liquid and treatment system technology, applied in the direction of gas treatment, separation methods, special treatment targets, etc., can solve the problems of poor treatment effect, high cost, high energy consumption, etc., to achieve reduced temperature difference, uniform liquid distribution, and liquid retention A large amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution adopted by the present invention will be further described below in combination with schematic diagrams.

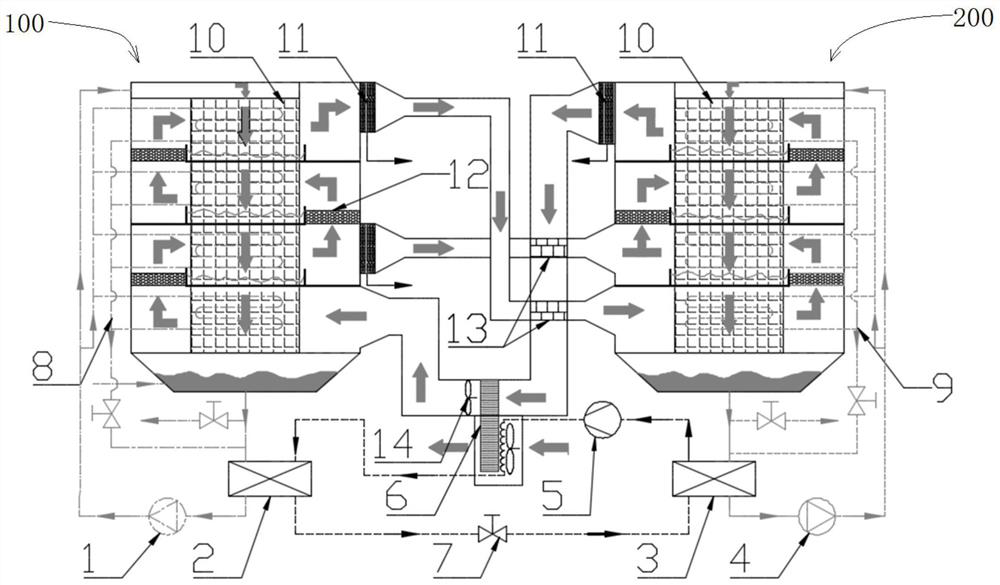

[0026] Such as figure 1 , an industrial waste liquid treatment system based on carrier gas extraction low temperature mass transfer (hereinafter referred to as "the system"), which includes: absorber 100, resolver 200, air circulation system, liquid circulation system and heat pump system.

[0027] from figure 1 It can be seen that the absorber 100 of this system is used to absorb the moisture in the waste liquid by using air, and the absorber adopts packing 10 to form a multi-stage cross-flow mass flow structure, and each layer is provided with a countercurrent rectification device 12 ( Such as a rectifier), the bottom of the absorber is provided with a waste liquid storage part and a waste liquid input port and a waste liquid output port arranged in the waste liquid storage part, and the cross section of the inner cavity of the waste liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com